Full-biodegradable high-temperature-resistant modified carbon dioxide-based transparent straw and preparation method thereof

A carbon dioxide and high temperature resistant technology, applied in the field of fully biodegradable high temperature resistant modified carbon dioxide-based transparent straws and their preparation, can solve the problems of high qualified rate of finished products, white pollution, consumption and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

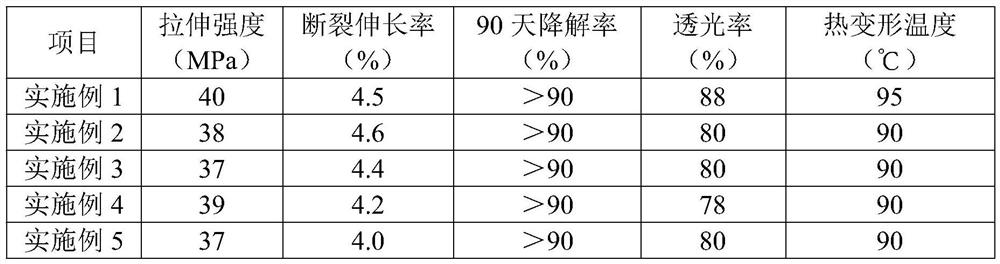

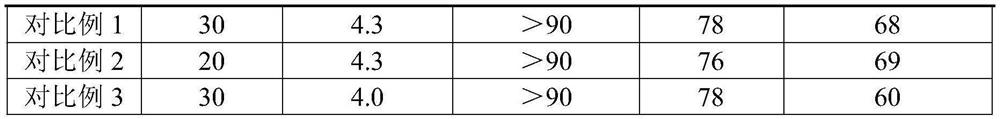

Examples

preparation example Construction

[0018] Another object of the present invention is to provide a method for preparing the fully biodegradable high-temperature-resistant modified carbon dioxide-based transparent straw, which is characterized in that it includes the following steps: after mixing the raw materials uniformly by weight, to obtain the mixed material, Then, the mixed material is added into a twin-screw extruder for melting and blending, extruded and granulated, cooled, and then drawn by a tube drawing machine, and then annealed to obtain a fully biodegradable high-temperature-resistant modified carbon dioxide-based transparent straw.

[0019] Preferably, the barrel temperature of the twin-screw extruder is 160-180°C, and the die head temperature is 170°C.

[0020] Preferably, the screw speed of the twin-screw extruder is 300-600 rpm, and the screw length-to-diameter ratio L / D is 52:1.

[0021] Preferably, the cooling method is air cooling.

[0022] Preferably, the temperature of the annealing treatm...

Embodiment 1

[0026] A fully biodegradable high-temperature-resistant modified carbon dioxide-based transparent straw is characterized in that it is made of the following raw materials in parts by weight: 5 parts of carbon dioxide-based PPC, 20 parts of PLA, 60 parts of PBS, 0.2 parts of dispersant, Compatibilizer 0.1 part, lubricant 0.1 part.

[0027] The lubricant is erucamide; the dispersant is ethylene bisstearamide; and the compatibilizer is compatibilizer CE2101.

[0028] Another object of the present invention is to provide a method for preparing the fully biodegradable high-temperature-resistant modified carbon dioxide-based transparent straw, which is characterized in that it includes the following steps: after mixing the raw materials uniformly by weight, to obtain the mixed material, Then, the mixed material is added into a twin-screw extruder for melting and blending, extruded and granulated, cooled, and then drawn by a tube drawing machine, and then annealed to obtain a fully b...

Embodiment 2

[0033] This example provides a fully biodegradable high-temperature-resistant modified carbon dioxide-based transparent straw, its formula and preparation method are basically the same as in Example 1, the difference is that it is made of the following raw materials in parts by weight: carbon dioxide-based PPC 6 25 parts of PLA, 63 parts of PBS, 0.23 parts of dispersant, 0.15 parts of compatibilizer, and 0.15 parts of lubricant.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com