Fracturing fluid and preparation method and application thereof

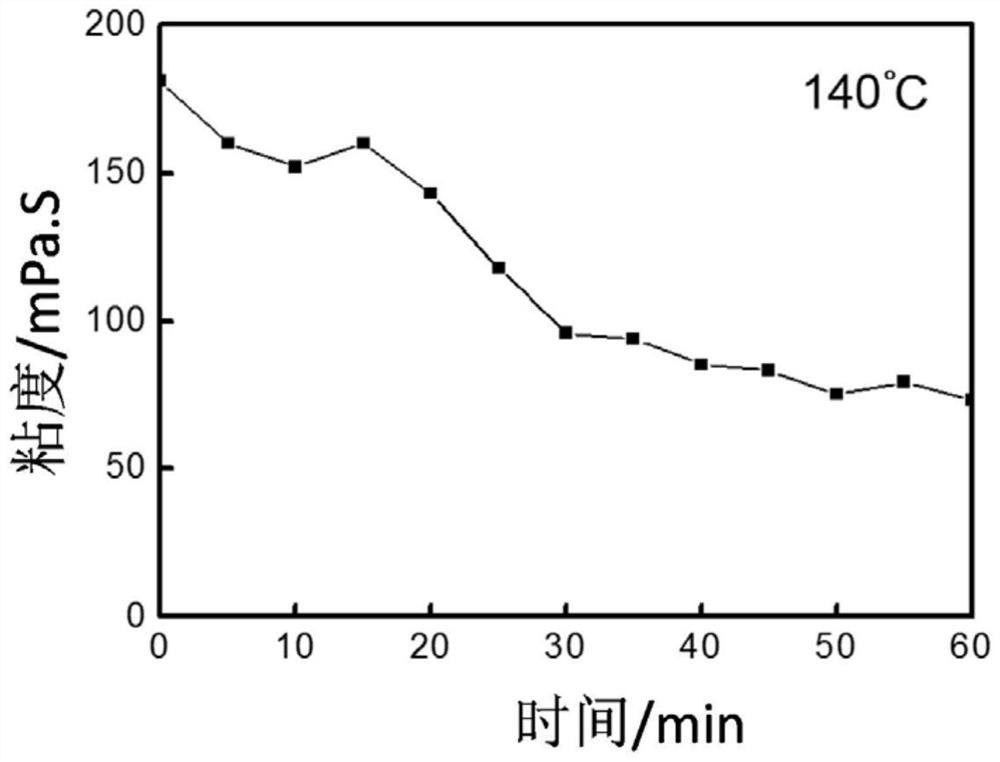

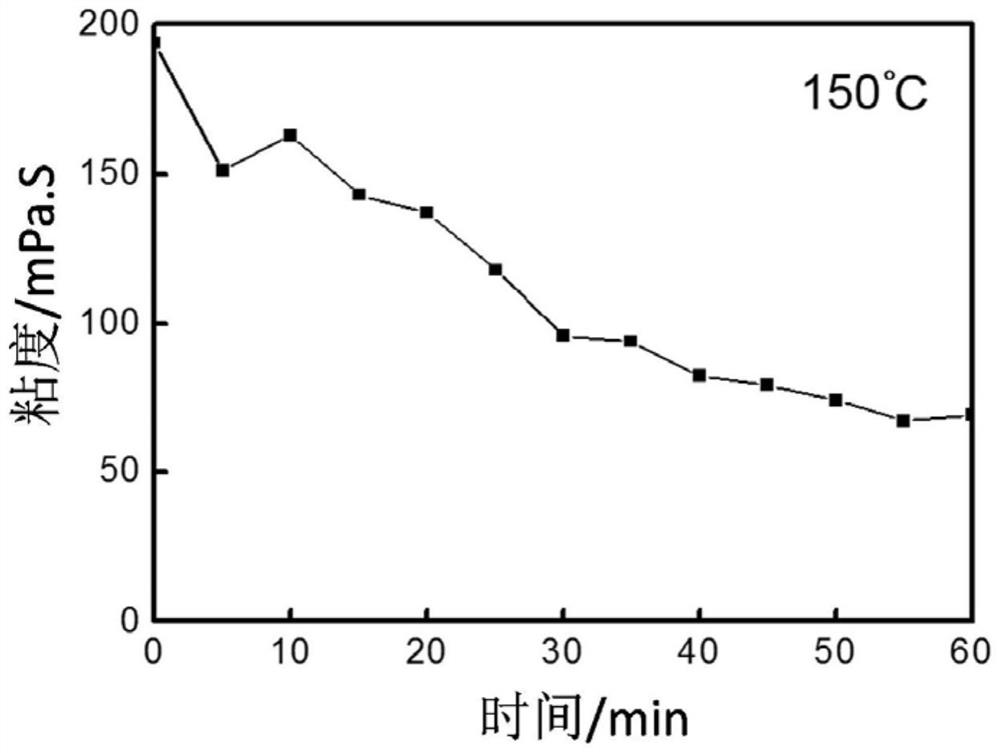

A fracturing fluid and solution technology, which is applied in the field of guar gum fracturing fluid, can solve the problems of high cost of fracturing fluid and damage to the reservoir due to the amount of usage, and achieve the effects of low price, strong temperature resistance, and reduced damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The present embodiment provides a kind of preparation method of fracturing fluid, it comprises:

[0037] Step 1, weigh borax, pseudoboehmite, ammonium chloride and water according to the mass ratio of 18.5:4.6:33:100, dissolve borax, pseudoboehmite and ammonium chloride in water, stir well and pour Put it into a high-pressure reactor and seal it; then place it in a muffle furnace at 580°C for 10 hours; then wash and dry the calcined product to obtain a crosslinking agent.

[0038] In step 2, the alkyl polyoxyethylene ether, isopropanol, alkyl polyglycoside and water are mixed in a mass ratio of 10:24:2:100 to obtain a drainage aid.

[0039] Step 3: Taking the total mass of the fracturing fluid as 100%, weigh 2‰ of carboxymethyl hydroxypropyl guar gum, 1.8‰ of the crosslinking agent prepared in Step 1, 2.5‰ of the drainage aid obtained in Step 2, and chlorinate Potassium 5‰, formaldehyde 0.35‰, polyoxyethylene polyoxypropylene pentaerythritol ether 0.35‰, sodium bicarbo...

Embodiment 2

[0044] The present embodiment provides a kind of preparation method of fracturing fluid, it comprises:

[0045] Step 1, weigh borax, pseudoboehmite, ammonium chloride and water according to the mass ratio of 20:5:30:100, dissolve borax, pseudoboehmite and ammonium chloride in water, stir well and pour Put it into a high-pressure reactor and seal it; then place it in a muffle furnace at 580°C for 10 hours; then wash and dry the calcined product to obtain a crosslinking agent.

[0046] In step 2, the alkyl polyoxyethylene ether, isopropanol, alkyl polyglycoside and water are mixed in a mass ratio of 13:29:2.4:100 to obtain a drainage aid.

[0047] Step 3: Taking the total mass of the fracturing fluid as 100%, weigh 2.5‰ of carboxymethyl hydroxypropyl guar gum, 2‰ of the cross-linking agent prepared in step 1, 2.1‰ of the drainage aid obtained in step 2, and chlorinate Ammonium 7‰, acrolein 0.25‰, polyoxyethylene polyoxypropylene alcohol amine ether 0.25‰, sodium bicarbonate 0.7...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com