Aluminum alloy profile quenching additive and quenching process

A technology of aluminum alloy profiles and additives, applied in the field of quenching liquid, can solve the problems of high toxicity of diisobutyl ketone, blackening of quenching agent, strong irritation, etc., to ensure consistent quality, reduce maintenance times, and excellent flame retardancy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1D

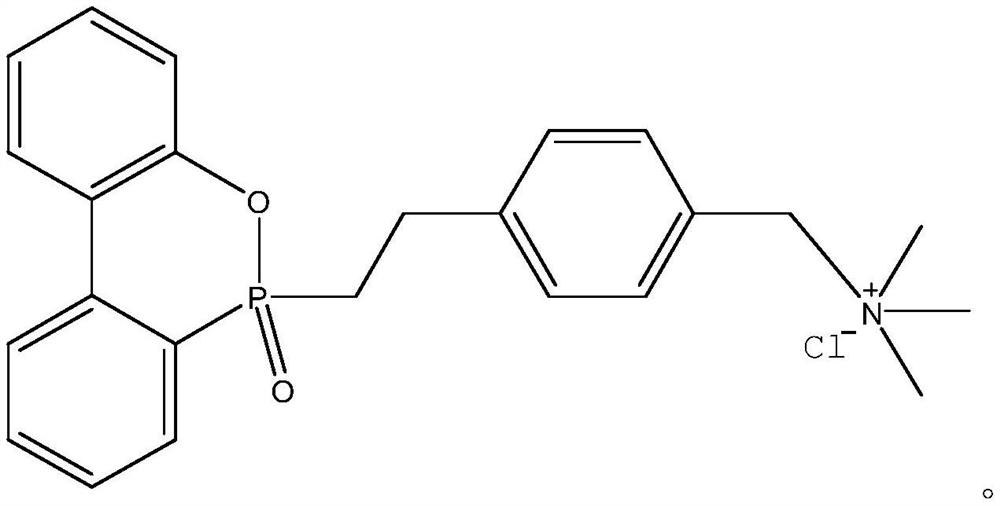

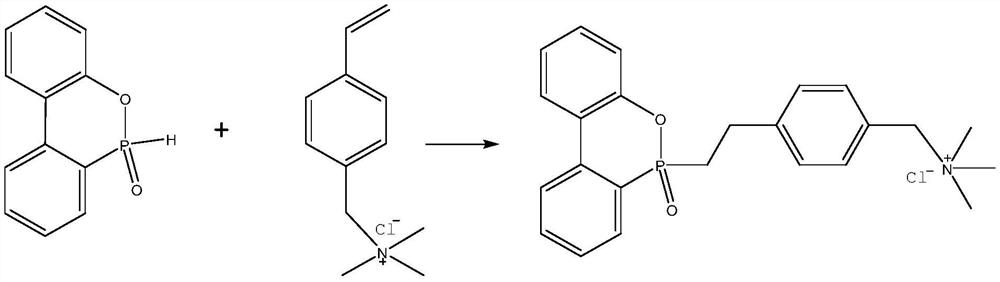

[0022] Example 1DOPO Derivative Synthesis

[0023]

[0024] 0.12 mol of DOPO, 0.1 mol n, N, N-trimethyl - pair of vinyl chloride (upper structure), 1 l-dichloromethane, stirred backflow for 2 h, after completion of the reaction, and the reaction was completed, and the reaction was completed, the reaction was completed. Liquid, evaporatedized 650 ml of dichloromethane, cooled crystallization, filtration, vacuum drying to give a white solid, yield 98%, HPLC purity 99.2%. 1 H-NMR (D-CCL) 3 PPM): 7.42 (m, 1H), 7.2 ~ 7.3 (m, 4H), 7.11 (S, 1H), 7.06 (m, 2H), 6.98 (M, 2H), 6.8 ~ 6.9 (M, 2H), 5.2 (m, 2H), 3.13 (m, 9H), 2.6 (m, 2H), 1.6 (m, 2H).

Embodiment 2

[0026] A total of 15 parts by weight of PAG stock, 85 parts by weight of deionized water were disposed of 100 parts by weight of the quenching agent. The quenching liquid uses in the production line of the company: The profile exit temperature is controlled at 550 ° C, continuously treats 2 tons of aluminum alloy profiles, and the surface of the profile begins to be bent, the streaks, etc., the quenching liquid is black, there is a odor, there is apodoa after 2 weeks later Flavor generation.

Embodiment 3

[0028] A total of 15 parts by weight of PAG stock, 8 parts by weight of the quenching additive, 77 parts by weight of deionized water;

[0029] Among them, 100 parts by weight of the quenching additive, 40 parts by weight of the polydimethylsiloxane, 30 parts by weight of benzalkonium chloride, and 30 parts by weight, DOPO derivative;

[0030] The hardening liquid is used in the company's production line: the export temperature of the profile is controlled at 550 ° C, and the aluminum alloy profile is continuously treated. The profile is good, but it has unequality (experimenting in the quenching liquid concentration), quenching color Slightly deep, no odor, no odor production after 2 weeks; supplement PAG, water, and additives to the initial value, the profile can be stably discharged.

[0031] Example 3

[0032] 20 parts by weight of PAG stock, 8 parts by weight of the quenching additive, 72 parts by weight of deionized water;

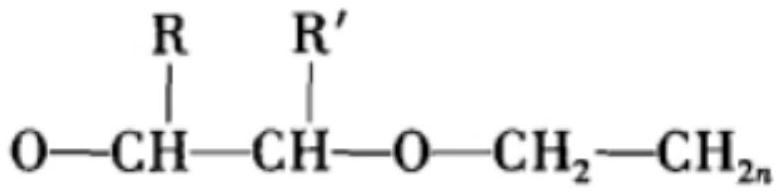

[0033] Among them, 100 parts by weight of the quen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com