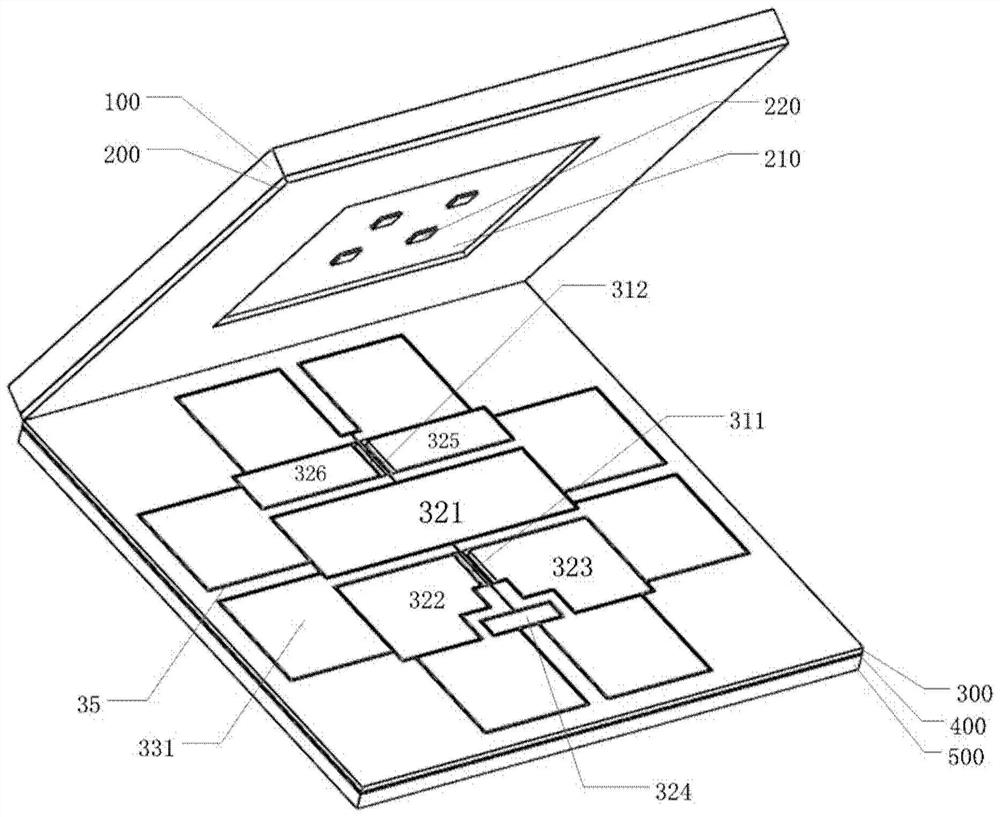

Resonant micro-pressure sensor and preparation method thereof

A micro-pressure sensor and resonant technology, which is applied in the field of MEMS micro-sensors, can solve the problems of high temperature sensitivity of the resonator, the influence of the comprehensive accuracy of the sensor, and high bonding voltage, so as to improve the pressure sensitivity, improve the anti-overload performance, and ensure the integrity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0074] The present invention also discloses a method for preparing the resonant micro-pressure sensor as described above, including:

[0075] S1: Etching the substrate layer 500 at the bottom of the SOI wafer to form a pressure sensitive film 530 and a first boss 510 disposed on the pressure sensitive film 530;

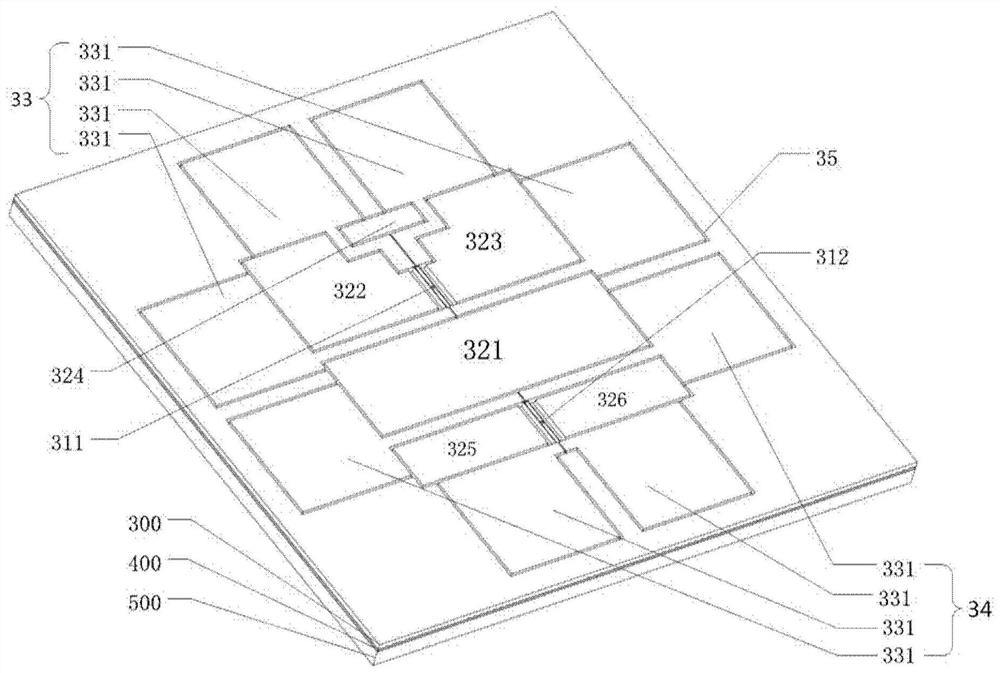

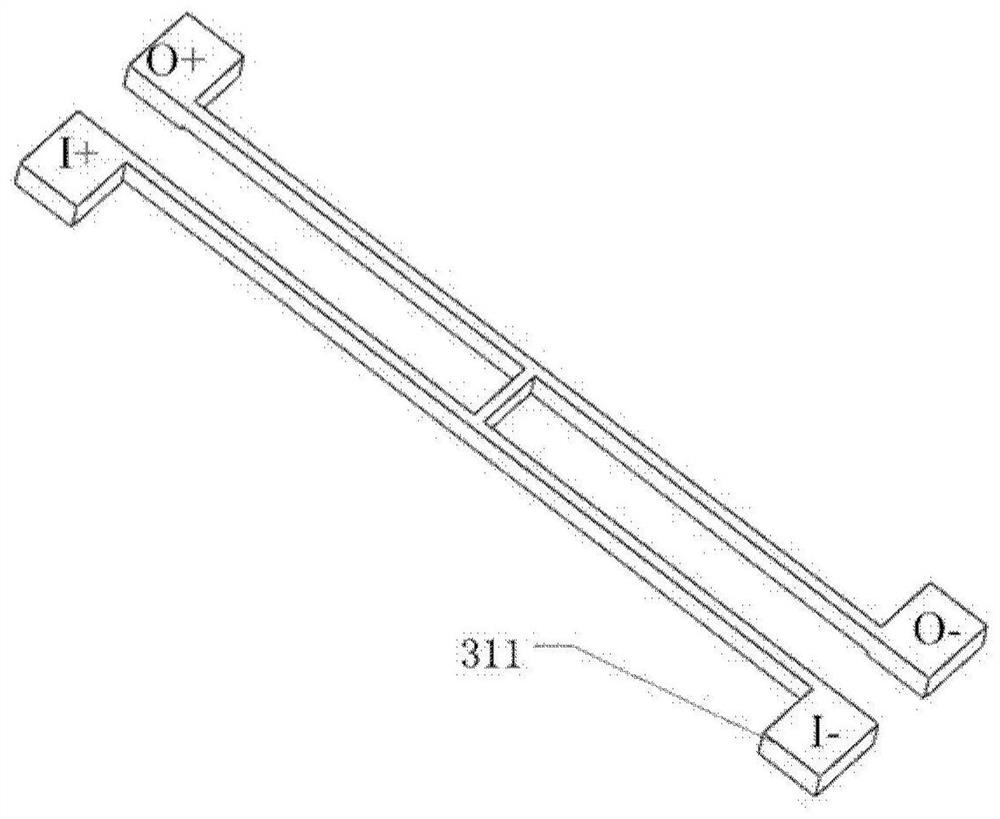

[0076] S2: Etching the device layer 300 on the top of the SOI wafer to form the first resonant unit 311, the second resonant unit 312 and the silicon island region;

[0077] S3: bonding the packaging cover plate to the SOI wafer in step S2 to obtain a resonant micro-pressure sensor, and completing the preparation of the resonant micro-pressure sensor.

[0078] In some embodiments of the present invention, the method for preparing the packaging cover plate described in step S4 includes:

[0079] S41: Etching the first cover layer 100 to obtain the first cover layer 100 provided with grooves for the first cover layer;

[0080] S42: preparing a second cover layer 200 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com