Self-healing hyperbranched polyurethane with high mechanical strength as well as preparation method and application thereof

A technology of hyperbranched polyurethane and mechanical strength, applied in the preparation of polyurethane and the field of hyperbranched polyurethane network, can solve the problems of low mechanical properties of self-healing hyperbranched polyurethane, and achieve enhanced self-healing performance, strong practicability, and preparation method. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

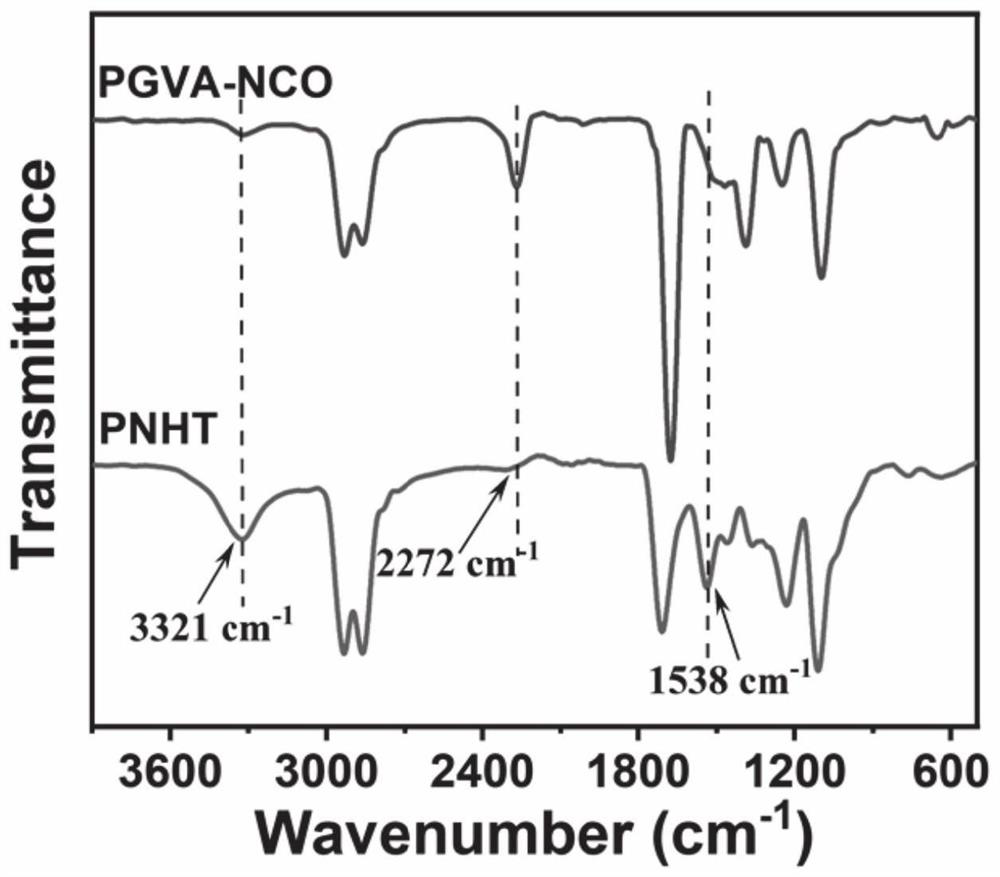

Method used

Image

Examples

preparation example Construction

[0054] The preparation method of hyperbranched polyester is:

[0055] Put glycerin and bismethylolpropionic acid at a molar ratio of 1:3 in a 250ml four-neck flask, add dibutyltin dilaurate as a catalyst, connect a water separator, a thermometer and a stirrer, and adjust the temperature under nitrogen protection. Raise to 140°C and stir, react for 3 hours, keep the temperature at 140°C, reduce the pressure to -0.1MPa to carry out polycondensation, and continue to react for 3 hours. A hyperbranched polyester is obtained.

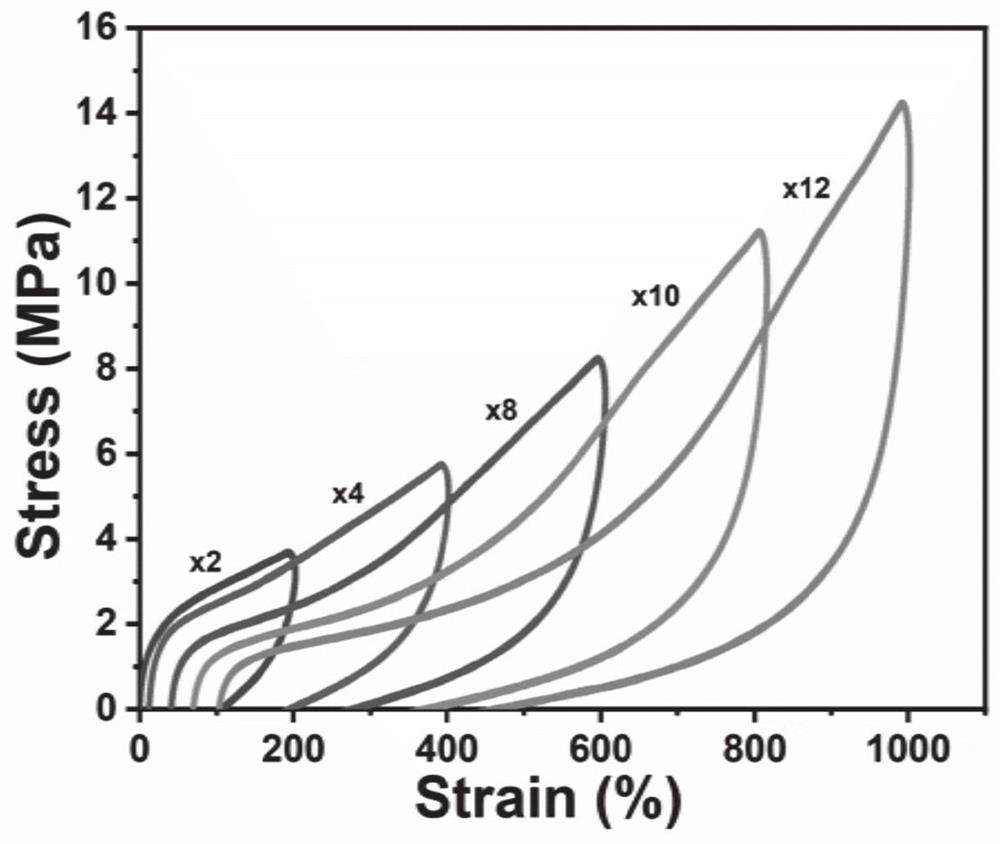

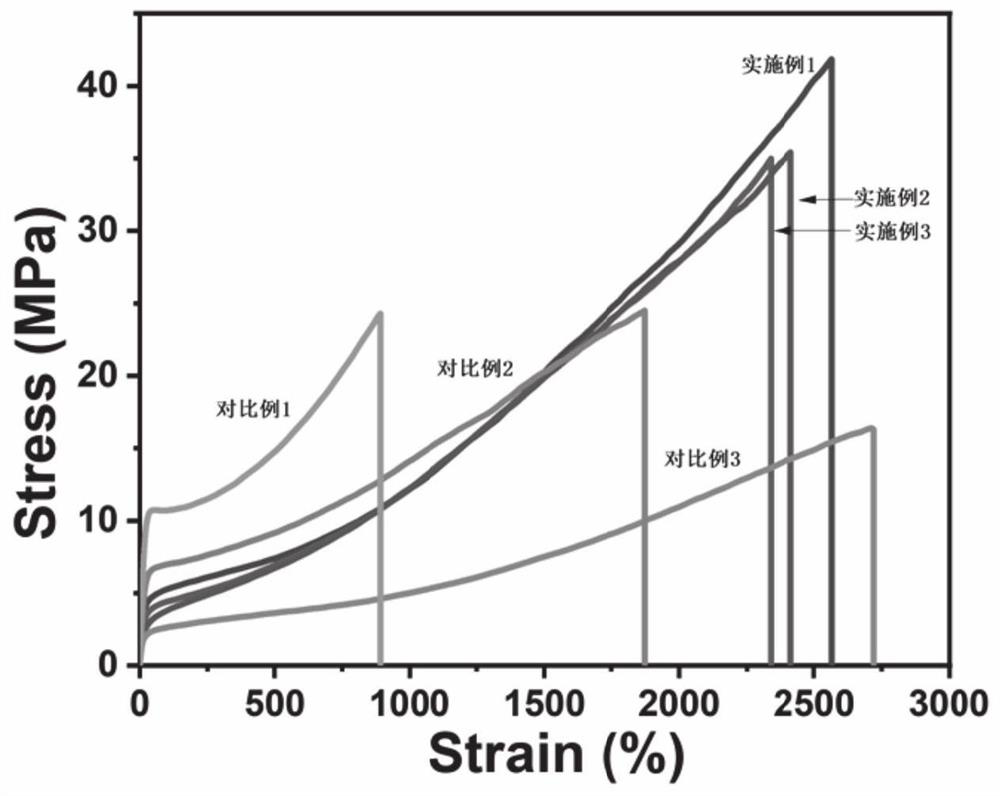

Embodiment 1

[0058] Put polytetrahydrofuran, VA and isophorone diisocyanate with a molar ratio of 1:0.15:2 in a 250ml four-neck flask, use N,N-dimethylformamide as a solvent, connect a spherical condenser, a thermometer and Stirrer, under the protection of nitrogen, the temperature was raised to 50° C. to dissolve and stir the raw materials, and then the temperature was raised to 75° C. to react for 3 hours to obtain a prepolymer of isocyanate-terminated polyurethane. Then, slowly add 2,4,6-triaminopyridine to the flask in an amount of 15% of the molar weight of isophorone diisocyanate, and add the catalyst dibutyltin dilaurate in an amount of 0.05% of the mass of PBIS , after the raw material is completely dissolved, react for 1h, then add hyperbranched polyester wherein, the add-on is 65% of the molar weight of isophorone diisocyanate, then add tannic acid therein, the add-on is isophorone diisocyanate 20% of the molar amount of isocyanate, under the protection of nitrogen, continue to r...

Embodiment 2

[0061] Put polytetrahydrofuran, VA and isophorone diisocyanate with a molar ratio of 1:0.4:2 in a 250ml four-neck flask, use N,N-dimethylformamide as a solvent, connect a spherical condenser, a thermometer and Stirrer, under the protection of nitrogen, the temperature was raised to 50° C. to dissolve and stir the raw materials, and then the temperature was raised to 70° C. to react for 2 hours to obtain a prepolymer of isocyanate-terminated polyurethane. Then, slowly add 2,4,6-triaminopyridine to the flask in an amount of 20% of the molar weight of isophorone diisocyanate, and add the catalyst dibutyltin dilaurate in an amount of 0.05% of the mass of PBIS , after the raw material is completely dissolved, react for 1h, then add hyperbranched polyester therein, the add-on is 50% of the molar weight of isophorone diisocyanate, then add tannic acid therein, the add-on is isophorone diisocyanate 30% of the molar amount of isocyanate, under the protection of nitrogen, continue to re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com