Recombinant bacillus methylotrophicus as well as construction method and application thereof

A technology of methylbutyric acid bacteria and methyl butyric acid, applied in the field of recombinant methyl butyric acid bacteria and its construction, to achieve the effect of increasing production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Example 1: Constructing recombinant plasmid pxy1-MTAA / MTAB / MTAC2

[0028] The genes used in the examples used in the examples are from buMe_rs16910, buMe_rs16905, buMe_rs16900, buMe_rs03485, buMe_rs03475, buMe_rs0347, respectively. Gene MATA, MTAB, MTAC2, ATOB, PAAH, CRT, BCD were endogenous endogenous genes, and the eatenylbutyrobacteria purchased from the ATCC strain preservation center.

[0029] Methanol overduction gene MTAb / MTAC2 / MTAA base sequence, that is, (methanol utilizing the pathway related gene SEQ NO.1):

[0030]atggcaaagaaatttgataaactggcaattaataatctggacgattttatttatggctcttgtccgaaccctgtcaccac caggagcggcatggtcatcggcggcggcaccatctatccggaaatcaacttcacactgccgggcatggatgtcaatgatc agaccattgacaaggccttgggcatttattccaatatcatcgacggtgtgctcaagagagcggcagagctctacgcgccc ggcgtgctggtagaatttgaaaccgtgccggactttaccgagcatccaaaatatgggattgacgccaaccgcattttatt aaatggcatcaaggaagccgcagacaagtacggcctcaaggccgccctgcggaccacccccaacgacctgcgcgaaatga gccgtcctccggttatgcgcggcggcaagtactgggataccat...

Embodiment 2

[0037] Example 2: Constructing recombinant strain BM / PXY1-MTAA / MTAB / MTAC2

[0038] Construction of recombinant strain BM / PXY1-MTAA / MTAb / mTAC2: Transformation of plasmid PMCljs into E. coli T1 / PMClJS to obtain recombinant strains, to prepare cells, specific steps As follows:

[0039] From the LB plate, a newly activated T1 / PMCLJS single colonies were seized in 5 ml of LB medium containing strong oxychromycin, and cultured at 37 ° C to a long period of time, and the strain was seeded in 50 ml of liquid medium. Medium, cultured to OD 37 ° C 600 = 0.4-0.5; Pour the bacterial liquid into the centrifuge tube, put 10 min on ice, 4000 rpm at 4 ° C for 10 min; discard the supernatant, with pre-cool 0.1 mol / L CaCl 2 The solution is 10 ml to gently suspend cells, placed on ice 15 min, 4000 rpm at 4 ° C for 10 min, repeat this step 2 times; discard the supernatant, add 5 mL to pre-cooling 15% glycerol 0.1 mol / l CaCl 2 The solution was gently suspended cells, and the ice wa...

Embodiment 3

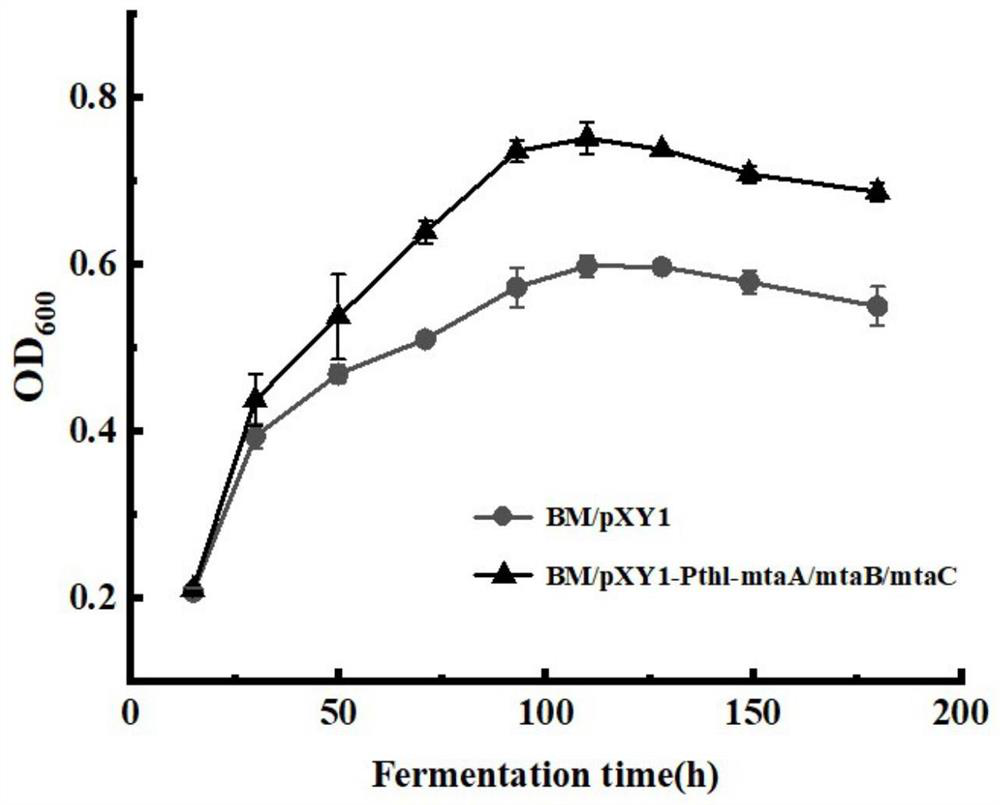

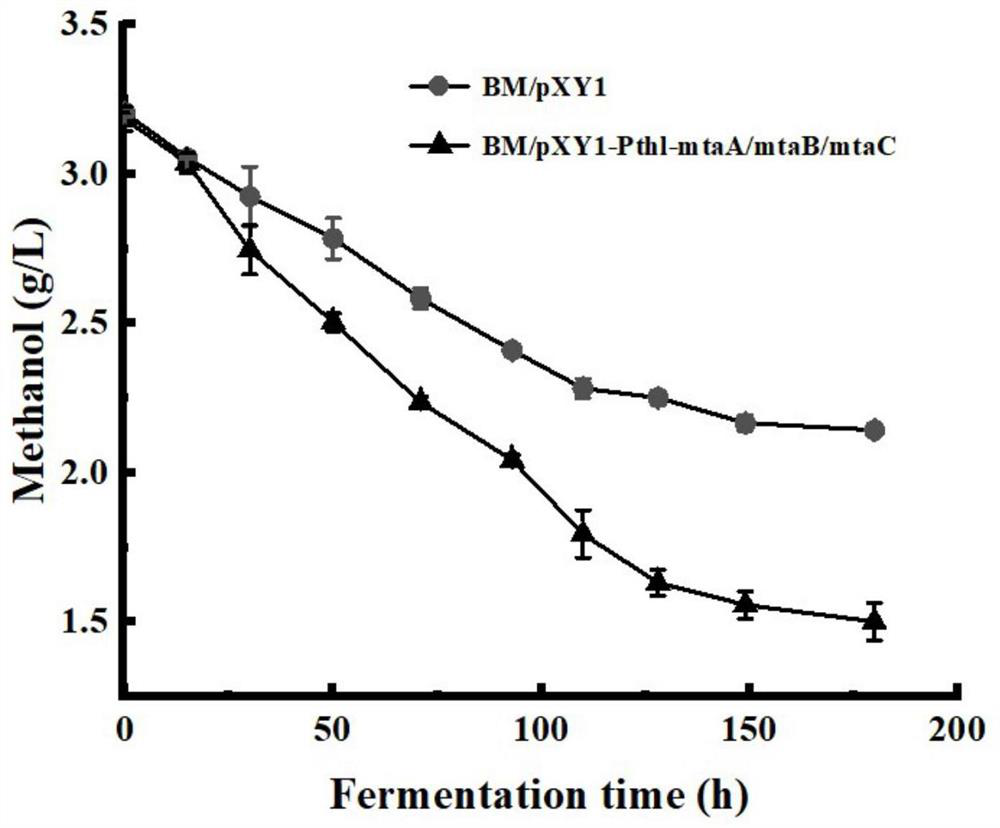

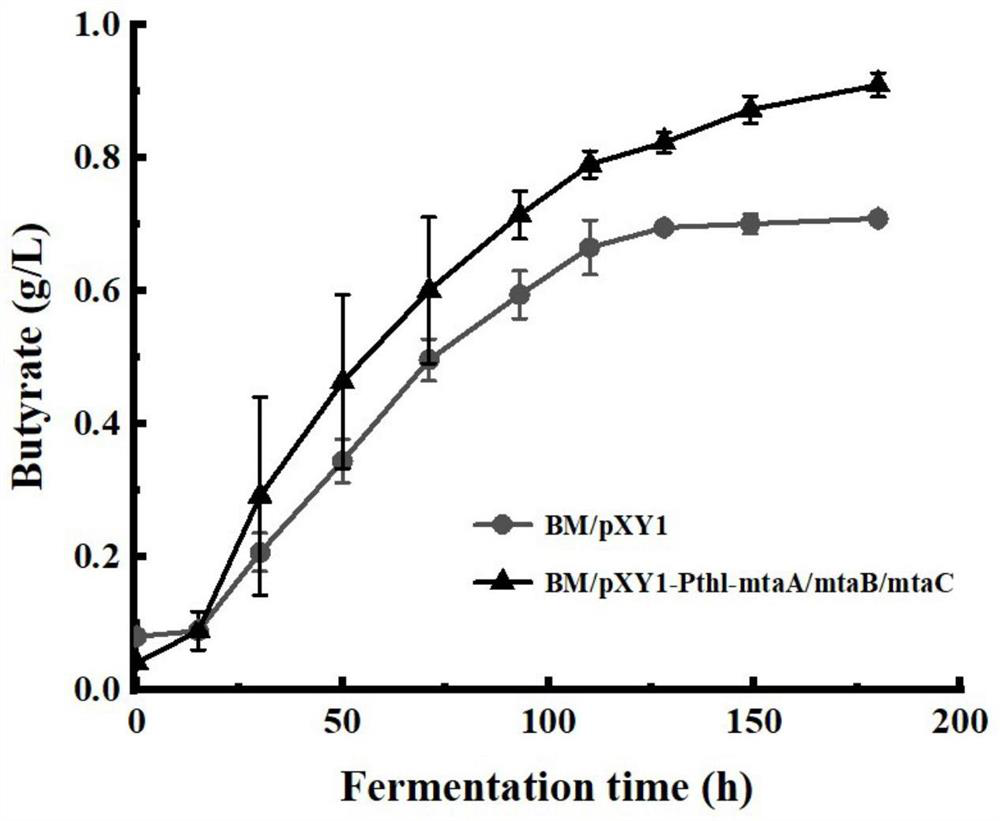

[0042] Example 3: Recombinant strain BM / PXY1-MTAA / MTAb / MTAC2 fermentation experiment

[0043] The recombinant strain BM / PXY1-MTAA / MTAB / MTAC2 single colonies were collected on the plate, which was inoculated to 1 ml YTF medium containing erythromycin (1 g / L, yeast powder 12g / L, sodium chloride 4g / L, glucose) In 5g / L), after 12-16 h, the bacterial liquid in the centrifuge tube was transferred to the annesate bottle, grown to OD. 600 For about 1, pour the bacterial solution into 50 ml of centrifuge tube, 4000 rpm centrifuge for 10min, discard the supernatant, use Pb medium to retain it with OD 600 The amount of inoculation of 0.1 was inoculated into 50 ml of Pb medium, and 100 mM methanol was added, and 2 ml of bacterial liquid was added every 24 h. After centrifugation, the supernatant was transferred to a new centrifuge tube, and methanol was used for high performance liquid chromatography. Butyric acid. Detect its OD after 2 ml of ultrapure water 600 , Compared...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com