Simple construction method of nano carbon shell loaded molybdenum-based heterojunction and application of nano carbon shell loaded molybdenum-based heterojunction in lithium-sulfur battery

A lithium-sulfur battery and nano-carbon technology, applied in the field of electrochemistry, can solve the problems of lack of in-depth research on catalysis, reduce the cost of lithium-sulfur batteries, and reduce the use of precious metal catalysts, so as to improve electrochemical performance, improve cycle, and improve adsorption. effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

[0046] (1) Nanocarbon shells were prepared by a template-free method.

[0047] Sodium citrate was dried in an oven at 140 °C for 12 h, ball milled for 6 h, and then the powder sample was transferred to a quartz boat and annealed at 700 °C for 1 h under an argon atmosphere with a heating rate of 5 °C / min. The resulting product was stirred in 2M HCl solution for 2 h and washed with copious amounts of deionized water. Dry at 60°C overnight to obtain the nano-carbon shell product;

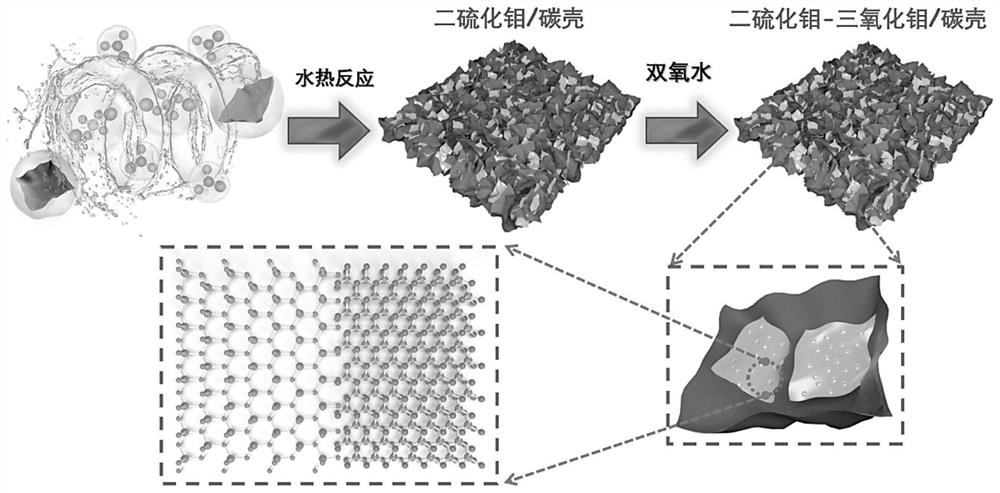

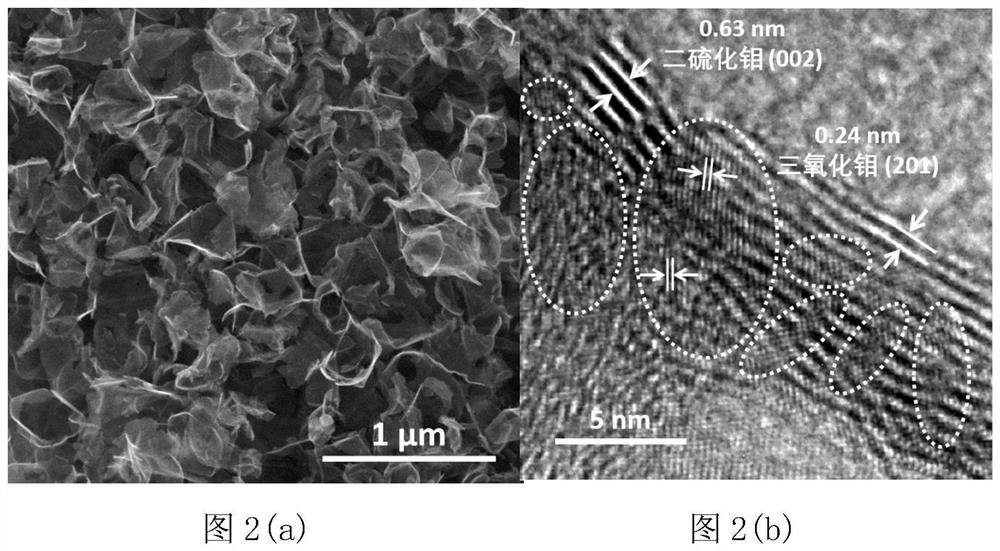

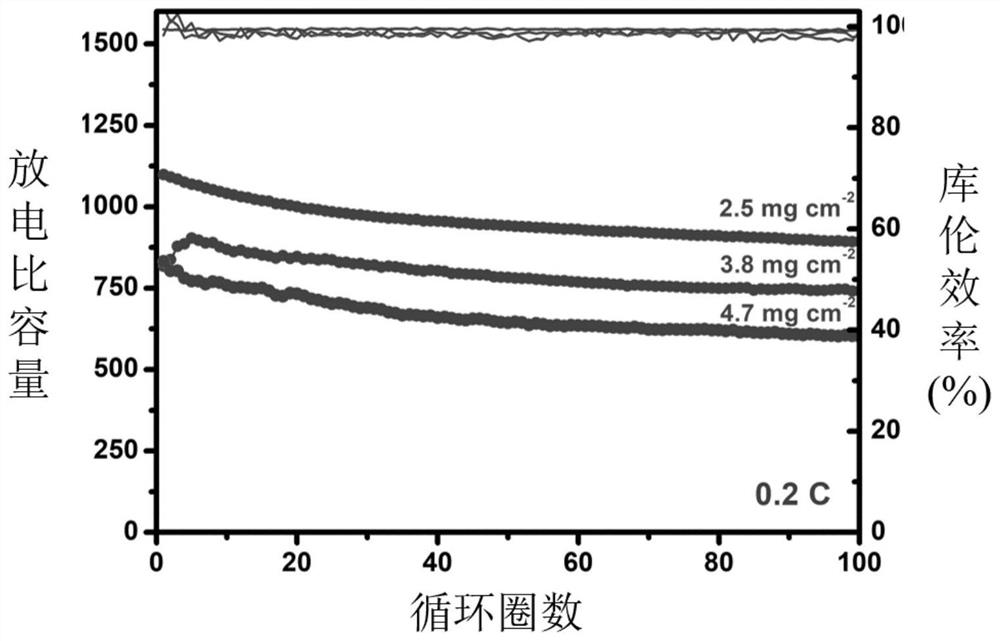

[0048] (2) Molybdenum disulfide / carbon shell material was prepared by hydrothermal method.

[0049] 50 mg of carbon shells were dispersed in 50 mL of deionized water and sonicated for 2 h, then 0.5 g of sodium molybdate dihydrate and 1 g of thiourea were added and stirred for 0.5 h. The solution was placed in a 100mL autoclave, sealed and heated at 200°C for 16h. The prepared solid product was washed with deionized water and dried in a vacuum oven at 60°C for 6 hours to obtain a molybdenum disulfide...

Embodiment example 2

[0060] (1) Nanocarbon shells were prepared by a template-free method.

[0061] Sodium citrate was dried in an oven at 160°C for 24h, ball milled for 12h, and then the powder sample was transferred to a quartz boat, annealed at 900°C for 3h under an argon atmosphere, and the heating rate was 5°C / min. The obtained product was stirred in 4M HCl solution for 6 h, washed with plenty of deionized water. Dry at 80°C overnight to obtain the nano-carbon shell product;

[0062] (2) Molybdenum disulfide / carbon shell material was prepared by hydrothermal method.

[0063] 150 mg of carbon shells were dispersed in 80 mL of deionized water and sonicated for 4 h, then 1.0 g of sodium molybdate dihydrate and 2 g of thiourea were added and stirred for 1 h. The solution was placed in a 100mL autoclave, sealed and heated at 200°C for 24h. The prepared solid product was washed with deionized water and dried in a vacuum oven at 60°C for 12 hours to obtain a molybdenum disulfide / carbon shell mate...

Embodiment example 3

[0074] (1) Nanocarbon shells were prepared by a template-free method.

[0075] Sodium citrate was dried in an oven at 150 °C for 20 h, ball milled for 9 h, and then the powder sample was transferred to a quartz boat, and annealed at 800 °C for 2 h under an argon atmosphere with a heating rate of 5 °C / min. The resulting product was stirred in 3M HCl solution for 4 h and washed with plenty of deionized water. Dry at 70°C overnight to obtain the nano-carbon shell product;

[0076] (2) Molybdenum disulfide / carbon shell material was prepared by hydrothermal method.

[0077] 100 mg of carbon shells were dispersed in 65 mL of deionized water and sonicated for 3 h, then 0.75 g of sodium molybdate dihydrate and 1.5 g of thiourea were added and stirred for 0.75 h. The solution was placed in a 100mL autoclave, sealed and heated at 200°C for 20h. The prepared solid product was washed with deionized water and dried in a vacuum oven at 70°C for 9 hours to obtain a molybdenum disulfide / ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com