Activated carbon composite material with three-dimensional porous structure and preparation method thereof

A technology of three-dimensional channels and composite materials, which is applied in the field of composite materials and preparations with three-dimensional channel structures, can solve the problems of poor adsorption effect, easy wear of activated carbon catalysts, insufficient driving force, etc., to improve the ability to deal with organic pollutants, The effect of improving the rapid adsorption capacity and increasing the adsorption reaction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

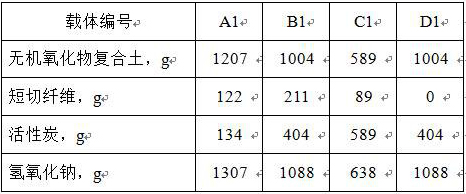

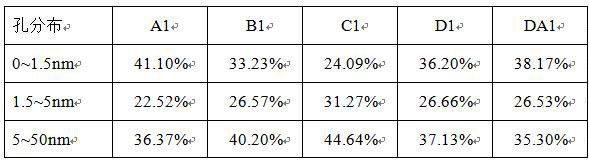

Embodiment 1

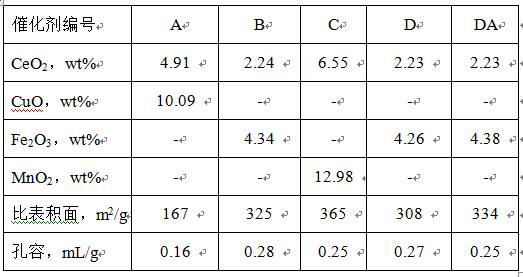

[0036] After mixing activated carbon and inorganic oxide composite soil treated at 700°C, add 10% by mass of alkali-soluble carboxymethyl cellulose fiber chopped slurry and mix evenly, then add 30% by mass of sodium silicate binder After kneading evenly, extrude into strips, dry at 90°C for 4 hours, and cure for 3 hours at 270°C under the protection of nitrogen to obtain a precursor. Take the precursor and add it to a sodium hydroxide solution with a mass concentration of 8.0%. After circulating the sodium hydroxide solution for 3 hours, filter it, dry the solid particles at 90°C for 6 hours, and roast them under the protection of nitrogen at 750°C for 3 hours to obtain the activated carbon composite carrier A1. The amounts of reagents used are listed in Table 1. The properties of the composite carrier are shown in Table 2.

[0037] The composite carrier A1 was taken, impregnated with an impregnation solution containing Ce-Cu, dried at 110°C for 10 hours, and calcined at 550°...

Embodiment 2

[0039] After mixing activated carbon and inorganic oxide composite soil treated at 800°C, add 20% by mass of alkali-soluble polyester cellulose fiber chopped slurry and mix evenly, then add 25% by mass of sodium silicate binder and knead After uniformity, extrude into strips, dry at 110°C for 4 hours, and cure for 3 hours at 270°C under the protection of nitrogen to obtain a precursor. Take the precursor and add it to a sodium hydroxide solution with a mass concentration of 7.0%. After circulating the sodium hydroxide solution for 3 hours, filter it, dry the solid particles at 110°C for 4 hours, and roast them under the protection of nitrogen at 650°C for 5 hours to obtain the activated carbon composite carrier B1. The amounts of reagents used are listed in Table 1. The properties of the composite carrier are shown in Table 2.

[0040] The composite carrier B1 was taken, impregnated with an impregnation solution containing Ce-Fe, then dried at 110°C for 10 hours, and calcined...

Embodiment 3

[0042] After mixing activated carbon and inorganic oxide composite soil treated at 900°C, add 15% by mass of alkali-soluble hydroxyethyl cellulose fiber chopped slurry and mix evenly, then add 30% by mass of sodium silicate binder After kneading evenly, extrude into strips, dry at 100°C for 6 hours, and cure for 3 hours at 300°C under the protection of nitrogen to obtain a precursor. Take the precursor and add it to a sodium hydroxide solution with a mass concentration of 8.0%. After circulating the sodium hydroxide solution for 4 hours, filter it, dry the solid particles at 110°C for 8 hours, and roast them under the protection of nitrogen at 700°C for 5 hours to obtain the activated carbon composite carrier C1. The amounts of reagents used are listed in Table 1. The properties of the composite carrier are shown in Table 2.

[0043] The composite carrier C1 was taken, impregnated with an impregnating solution containing Ce-Mn, then dried at 110°C for 10 hours, and calcined a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com