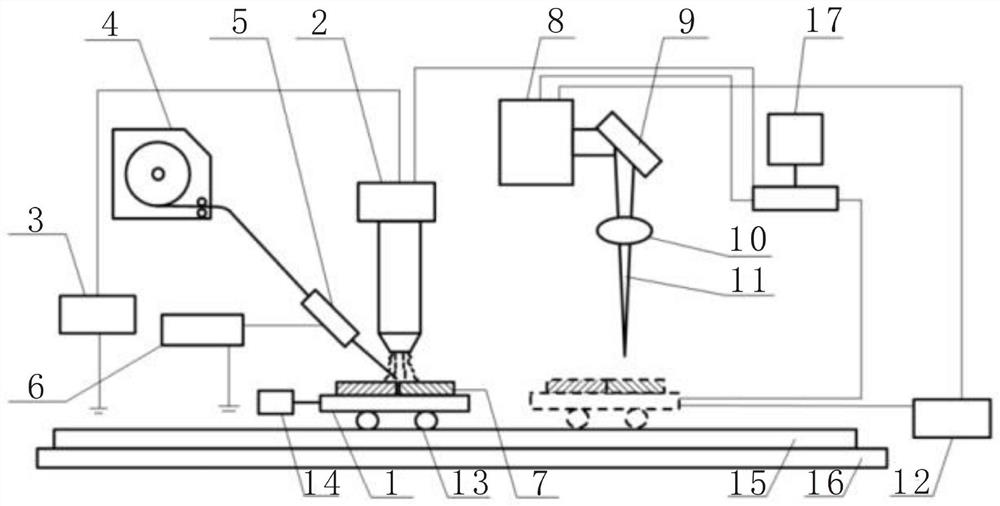

Fusion welding and laser shock strengthening composite manufacturing device and method

A technology of laser shock strengthening and manufacturing equipment, which is applied in manufacturing tools, welding equipment, arc welding equipment, etc., can solve the problems of difficulty in guaranteeing the quality of fusion welding seams, high labor intensity of welders, and low production efficiency, so as to alleviate the overall performance. The effect of lowering, lower working environment requirements, and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

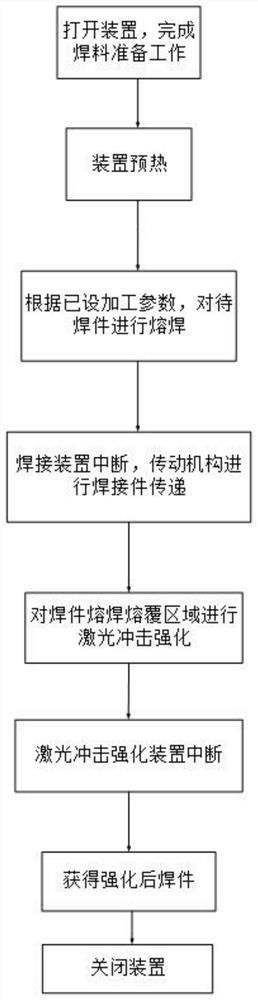

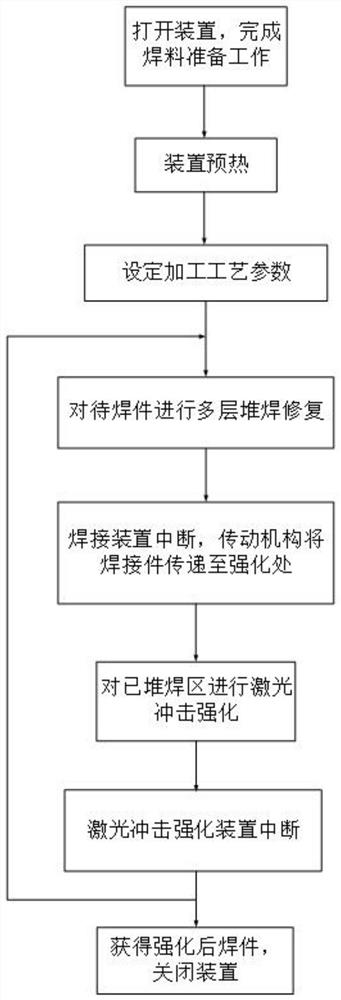

Method used

Image

Examples

Embodiment

[0079] In this embodiment, austenitic stainless steel 316L and Incoloy825 nickel-based superalloy dissimilar plates are used as materials, and TC17 titanium alloy welding wire with a diameter of 1.6 mm is used as the welding wire. The size of the plate is the same as 120mm*150mm*100mm. After fixing, the sample is mechanically polished and cleaned with acetone. After the preparation work is completed, the specific implementation steps are as follows:

[0080] 1) Turn on the power supply of the overall device and the computer control system 17, detect the connection and operation of each device to ensure normal operation, and set the arc welding manufacturing process parameters and laser shock strengthening process parameters;

[0081] 2) The welding process is realized through the arc welding manufacturing device, wherein the main process parameters of the arc welding are: the welding acceleration voltage is 60V, the welding current is 500A, and the welding speed is 200mm / min; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com