Large-scale energy-saving production device and process for preparing ethylene glycol through dimethyl oxalate hydrogenation

A technology of dimethyl oxalate and production equipment, which is applied in the field of chemical technology, can solve the problems of high power consumption and steam consumption, reduce the enterprise's anti-risk ability, and the operating rate is less than 50%, so as to reduce equipment investment and steam consumption , the effect of reducing direct or indirect costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

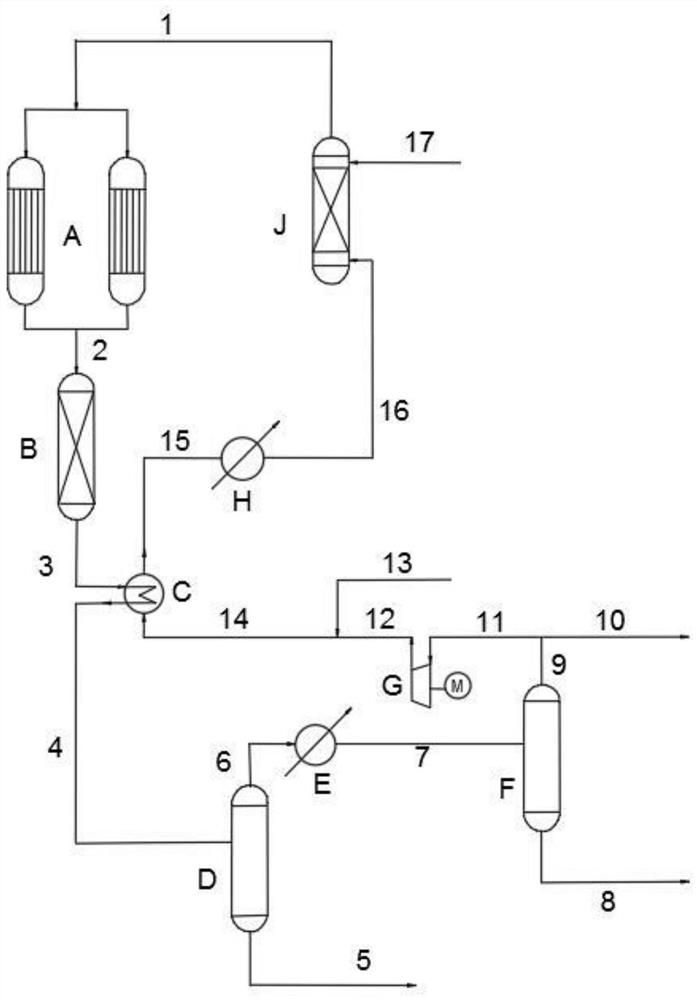

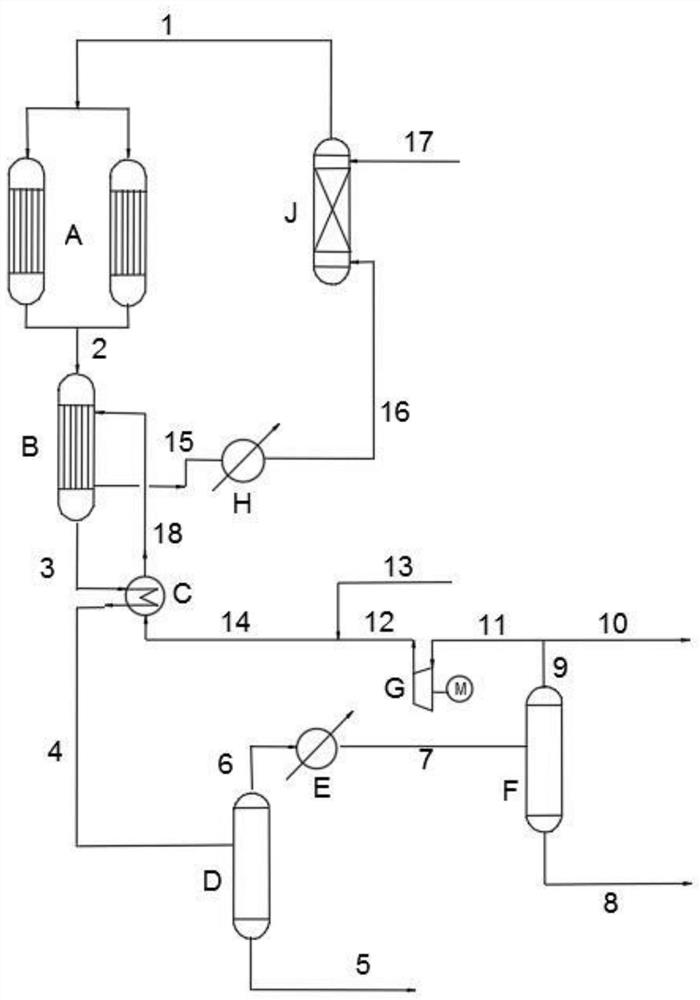

[0043] see figure 1 As shown, taking the production process of ethylene glycol with an annual output of 400,000 tons / year as an example, a large-scale energy-saving production device for hydrogenating dimethyl oxalate to ethylene glycol in this specific embodiment has a structure comprising:

[0044] Gasification device J, the entire reactor group consisting of two parallel first synthesis reactors A and a single second synthesis reactor B, heater H, feed-in and out-feed heat exchanger C, first high-pressure separation tank D, second Two high-pressure separation tank F;

[0045] The gasification device J is connected to the first synthesis reactor A through the first synthesis reactor inlet gas pipeline 1, and the second synthesis reactor B and the first synthesis reactor A are connected through the second synthesis reactor inlet gas pipeline 2 In series, the gasification device J and the heater H are connected through the gasification device circulation gas pipeline 16; the ...

specific Embodiment 2

[0057] The process flow is the same as that of Example 1, except that the first synthesis reactor A adopts three tubular reactors connected in parallel, and one second synthesis reactor B connected in series. The cylinder diameter of the first synthesis reactor A is 4.2m, the height of the reactor tube bundle is 6.0m, the inner diameter of the tube bundle is 34mm, the tube spacing is 45mm, and the catalyst loading volume of the single first synthesis reactor A is 38.24m 3 ; The second synthesis reactor B is an adiabatic reactor, the diameter of the reactor cylinder is 4.2m, the height of the cylinder is 7.2m, and the catalyst loading volume of the second synthesis reactor is 98.62m 3 .

[0058] Under the design conditions of this process, the pressure drop of the reactor group is 105KPa, and the pressure drop of the synthesis loop is 185KPa. Compared with the scheme of using multiple tube reactors in series, the pressure drop of the synthesis loop is more than 75KPa. The powe...

specific Embodiment 3

[0060] The process flow is the same as that of Example 1, except that the first synthesis reactor A adopts two plate reactors connected in parallel, and one second synthesis reactor B connected in series. The cylinder diameter of the first synthesis reactor A is 4.2m, the plate height is 6.4m, the distance between metal plates is 6mm, the distance between plate pairs is 32mm, and the catalyst loading volume of a single first synthesis reactor is 58.41m 3 ; The second synthesis reactor B is an adiabatic reactor, the diameter of the reactor cylinder is 4.2m, the height of the cylinder is 7.0m, and the catalyst loading volume of the second synthesis reactor is 96.51m 3 .

[0061] Under the design conditions of this process, the pressure drop of the reactor group is 115KPa, and the pressure drop of the synthesis loop is 195KPa. Compared with the scheme of using multiple tube reactors in series, the pressure drop of the synthesis loop is more than 75KPa. The power of the circulati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com