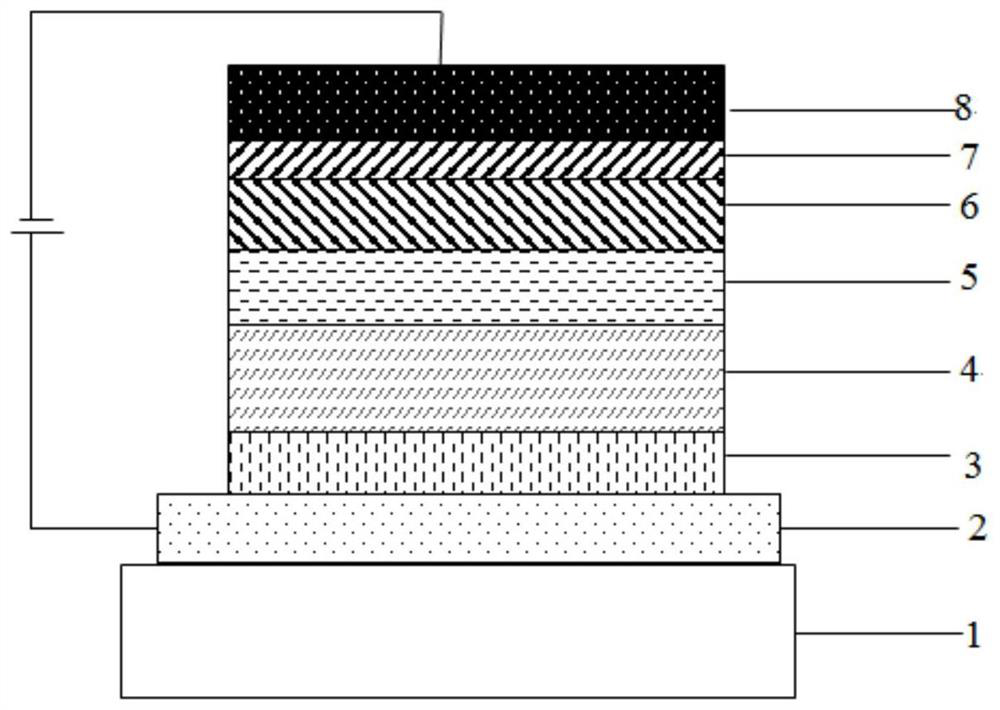

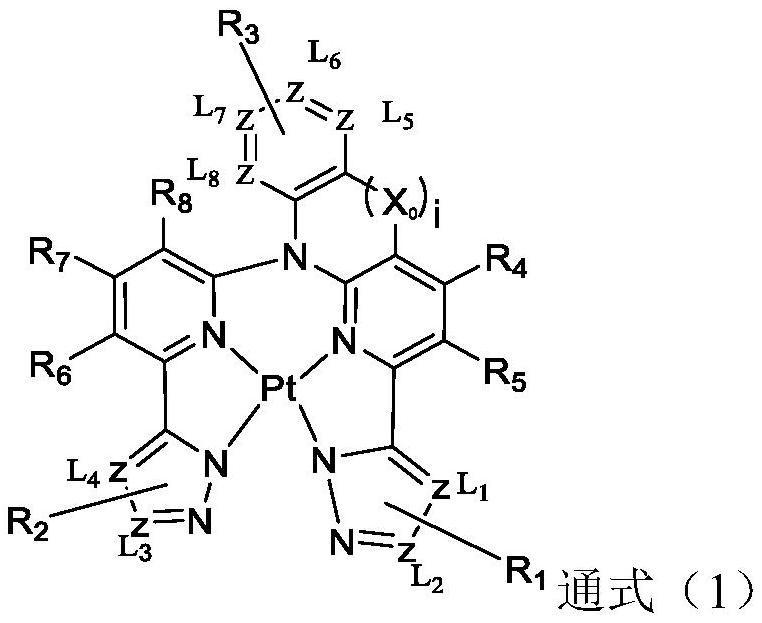

A kind of organic electroluminescent material containing metal platinum and its application

An electroluminescent material, metal platinum technology, applied in luminescent materials, organic chemistry, circuits, etc., can solve the problems of unsatisfactory life performance and achieve good industrialization prospects, good material stability, and narrow spectral half-peak width Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

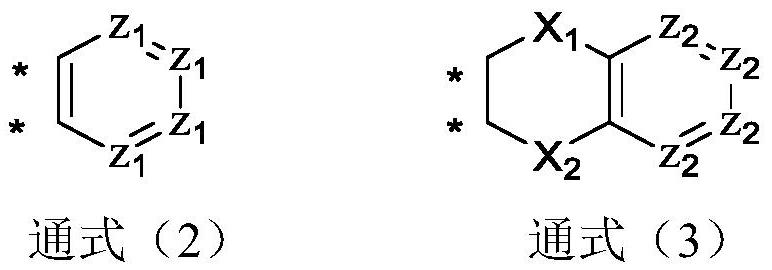

[0054] The specific reaction types involved in the preparation of the compounds of the present invention are classified as follows:

[0055] Reaction condition 1:

[0056] In a 250mL three-neck flask, under nitrogen protection, 0.02mol reactant A, 0.022mol reactant B, 0.05mol sodium tert-butoxide, 0.2mmol Pd 2 (dba) 3 , 0.2 mmol of tri-tert-butylphosphine was added to 150 mL of toluene, stirred and mixed, heated to 110-120 ° C, refluxed for 12-16 hours, and the reaction was complete; naturally cooled to room temperature, filtered, and the filtrate was rotary evaporated under reduced pressure until there was no distillate. Neutral silica gel column to obtain the product.

[0057] Reaction condition 2:

[0058] Add 0.05mol of reactant C, 41.6g of N-bromosuccinimide (NBS), 500mL of dichloromethane and 500mL of acetonitrile into the three-necked flask in sequence, and stir at room temperature for 24h. After the reaction, the precipitated solid product is vacuum pumped Filtrati...

preparation Embodiment 1

[0079]

[0080] Under a nitrogen atmosphere, weigh 0.01mol of reactant S-1 and dissolve it in 45mL of tetrahydrofuran, cool down to -78°C, slowly drop into a cyclohexane solution containing 0.02mol of n-butyllithium, after the dropwise addition, keep stirring for 30 minutes Slowly add a tetrahydrofuran solution containing 0.035mol trimethyl borate dropwise. After the dropwise addition, slowly warm up to room temperature and keep warm for 10 hours. After the reaction, cool down to 0°C and slowly drop in distilled water. Stir for 1 hour, then rise to room temperature; extract the reaction solution with 150 mL of ethyl acetate, wash the extract with 150 mL of saturated brine three times, and finally dry over anhydrous magnesium sulfate, and distill the solution under reduced pressure, and distill the obtained solid with 400 mL of V 甲苯 :V 乙醇 =3:1 mixed solution was recrystallized to obtain E-1.

[0081] In a 250mL three-neck flask, under nitrogen protection, 0.02mol reactant A...

preparation Embodiment 2

[0086]

[0087] Under a nitrogen atmosphere, weigh 0.01mol of reactant S-2 and dissolve it in 45mL of tetrahydrofuran, cool down to -78°C, slowly drop into a cyclohexane solution containing 0.02mol of n-butyllithium, after the dropwise addition, keep stirring for 30 minutes Slowly add a tetrahydrofuran solution containing 0.035mol trimethyl borate dropwise. After the dropwise addition, slowly warm up to room temperature and keep warm for 10 hours. After the reaction, cool down to 0°C and slowly drop in distilled water. Stir for 1 hour, then rise to room temperature; extract the reaction solution with 150 mL of ethyl acetate, wash the extract with 150 mL of saturated brine three times, and finally dry over anhydrous magnesium sulfate, and distill the solution under reduced pressure, and distill the obtained solid with 400 mL of V 甲苯 :V 乙醇 =3:1 mixed solution was recrystallized to obtain E-2.

[0088] In a 250mL three-neck flask, under nitrogen protection, 0.02mol reactant A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com