Green and environment-friendly metal cutting fluid and preparation method thereof

A metal cutting fluid, green and environmentally friendly technology, applied in the field of metal cutting processing, can solve the problem of difficult degradation of metal cutting fluid, and achieve the effects of easy handling, good emulsification stability, and excellent cleaning performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

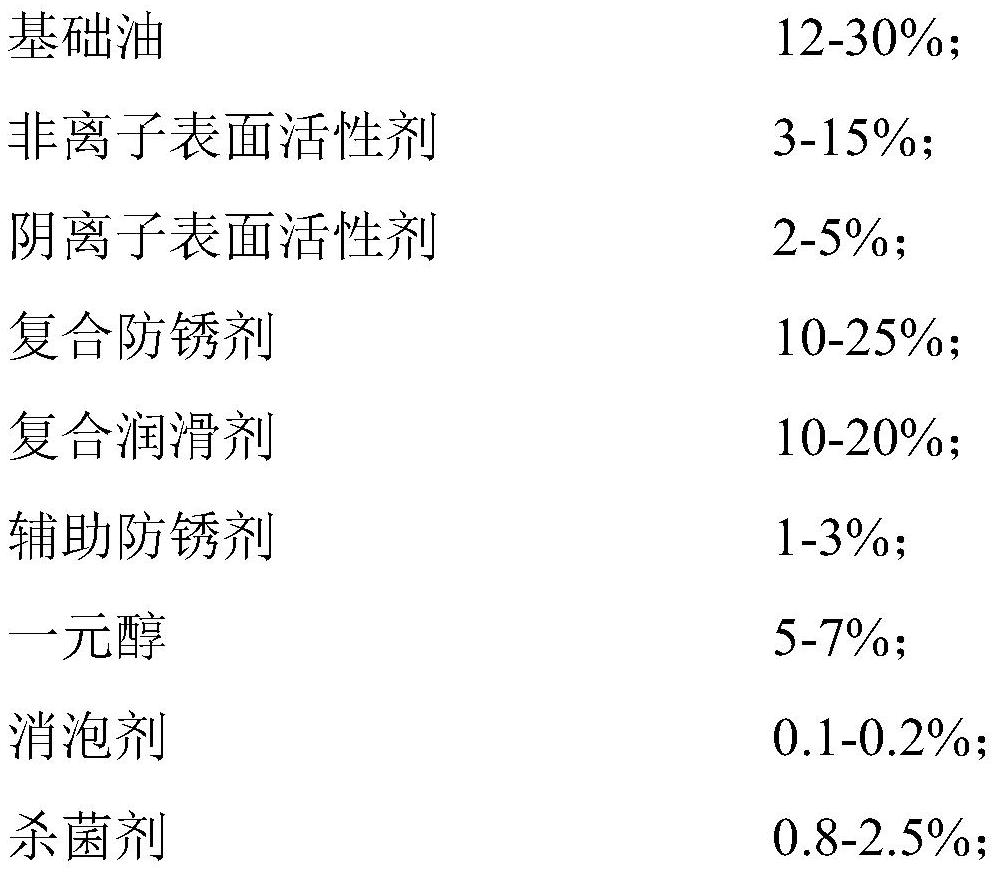

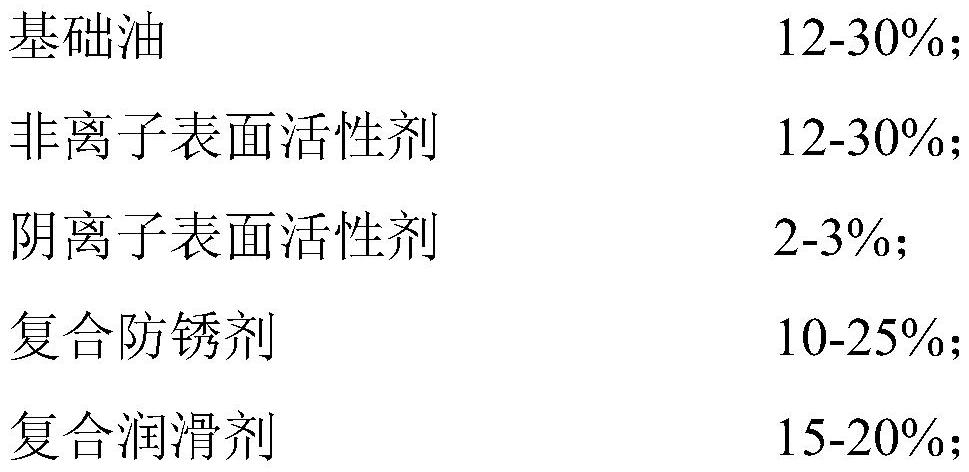

Method used

Image

Examples

preparation example Construction

[0046] A preparation method of a green and environment-friendly metal cutting fluid, comprising the following steps:

[0047] 1) the reactor is heated to 60-80 ℃, then add boric acid and triethanolamine to mix with mass ratio 1:(2-2.5), and stirring reaction 30-40min, obtains the boric acid triethanolamine ester with antirust effect;

[0048] 2) sequentially adding monoethanolamine, isopropanolamine, 1,2,3-benzotriazole and stirring for 15-30min to form a composite rust inhibitor;

[0049] 3) Add pure water to flush the raw materials on the reactor wall into the system, and stir for 20-40min;

[0050] 4) Cool down to 30-40℃, add compound lubricant and auxiliary rust inhibitor and stir for 20-40min;

[0051] 3) Add nonionic surfactant, monohydric alcohol and base oil, and stir for 20-40min;

[0052] 4) Add remaining water, anionic surfactant, bactericide and defoaming agent, and stir until the solution is clear and transparent to obtain metal cutting fluid.

Embodiment 1

[0056] A preparation method of a green and environment-friendly metal cutting fluid, comprising the following steps:

[0057] 1) the reactor is heated to 70 ℃, then the mixture of (5%) boric acid and triethanolamine is added successively (boric acid and triethanolamine mass ratio are 1:2), and stirring reaction 30min obtains boric acid triethanolamine ester;

[0058] 2) successively add (5%) isopropanolamine, (7%) monoethanolamine, (4%) lauric acid, (0.2%) 1,2,3-benzotriazole and stir for 15min to form a composite Rust inhibitor;

[0059] 3) Add (10%) pure water to flush the raw materials on the reactor wall into the system, and stir for 30min;

[0060] 4) Cool down to 35°C, add a composite lubricant consisting of (3%) ricinoleic acid, (8%) hexameric ricinoleic acid, (0.5%) vegetable oleic acid, and (3%) antirust agent dicyclohexyl Amine and stirred for 30min;

[0061] 5) Add (6%) 1-dodecanol, (5%) non-ionic surfactant isotridecyl alcohol polyoxyethylene ether and (13%) biodi...

Embodiment 2

[0065] A preparation method of a green environment-friendly metal cutting fluid, comprising the following steps:

[0066] 1) Heat the reactor to 70°C, then add (7%) a mixture of boric acid and triethanolamine in sequence (the mass ratio of boric acid to triethanolamine is 1:2), and stir for 30 minutes to obtain triethanolamine borate;

[0067] 2) Add (6%) isopropanolamine, (6%) monoethanolamine, (5%) lauric dibasic acid, (0.1%) 1,2,3-benzotriazole in sequence and stir for 15 minutes to form a compound Rust inhibitor;

[0068] 3) Add (12%) pure water to flush the raw materials on the wall of the reactor into the system, and stir for 30 minutes;

[0069] 4) Cool down to 35°C, add a compound lubricant consisting of (2%) ricinoleic acid, (8%) hexameric ricinoleic acid, (0.5%) vegetable oleic acid, and (2%) auxiliary antirust agent bicyclic Hexylamine and stirred for 30min;

[0070] 5) Add (5%) 1-tetradecyl alcohol, (3%) nonionic surfactant isotridecyl alcohol polyoxyethylene et...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com