Silicon carbide device, preparation method thereof and semiconductor device

A technology of silicon carbide and devices, which is applied in semiconductor devices, semiconductor/solid-state device manufacturing, electrical components, etc., and can solve problems such as demanding driving requirements, large leakage currents, and false openings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

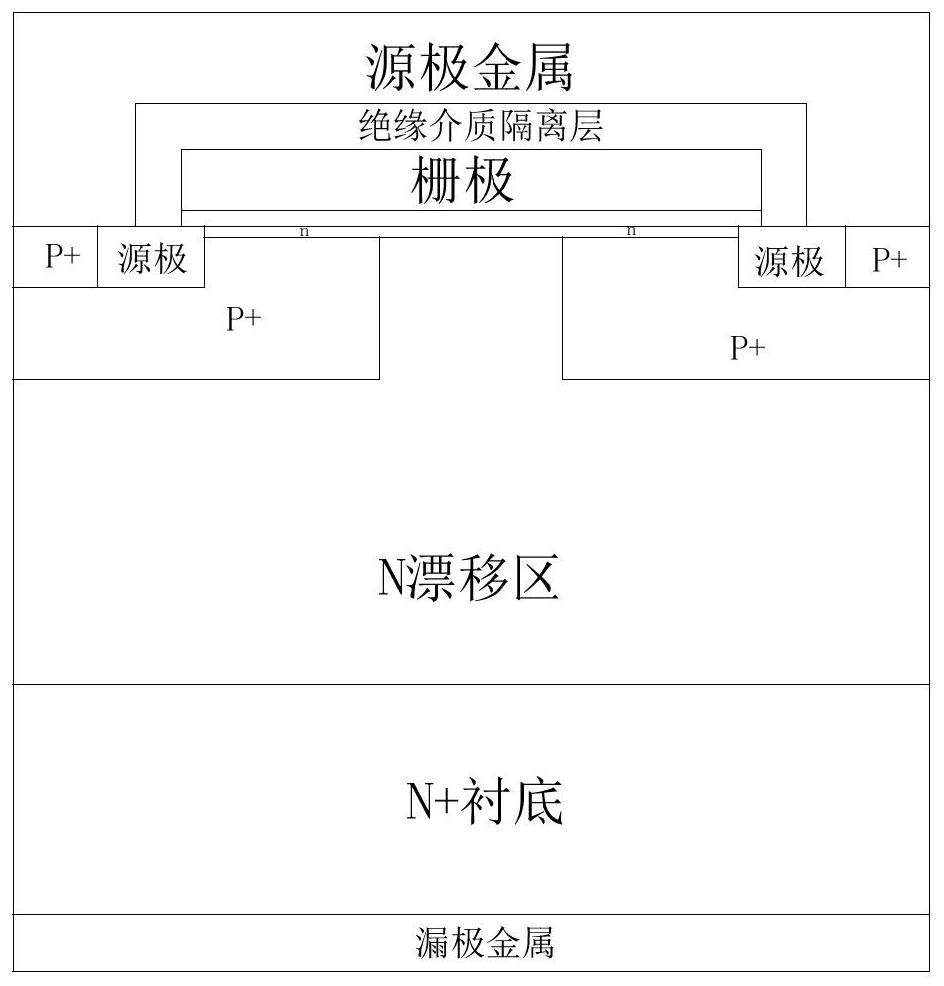

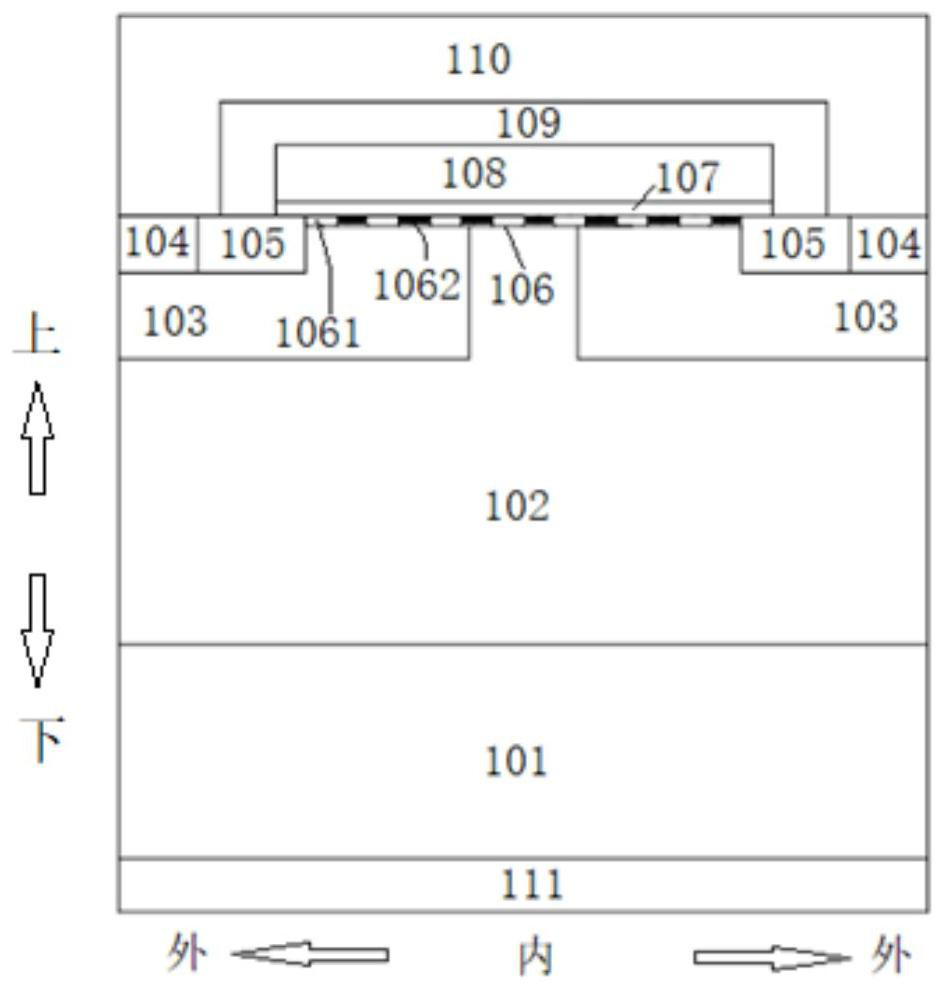

[0043] 1. Epitaxially grow a layer of drift region on the substrate to form a wafer for making silicon carbide devices;

[0044] 2. Form a p-hydrazine region on the upper surface of the wafer by photolithography implantation

[0045] 3. A thin n-type epitaxial layer is epitaxially formed on the surface of the wafer;

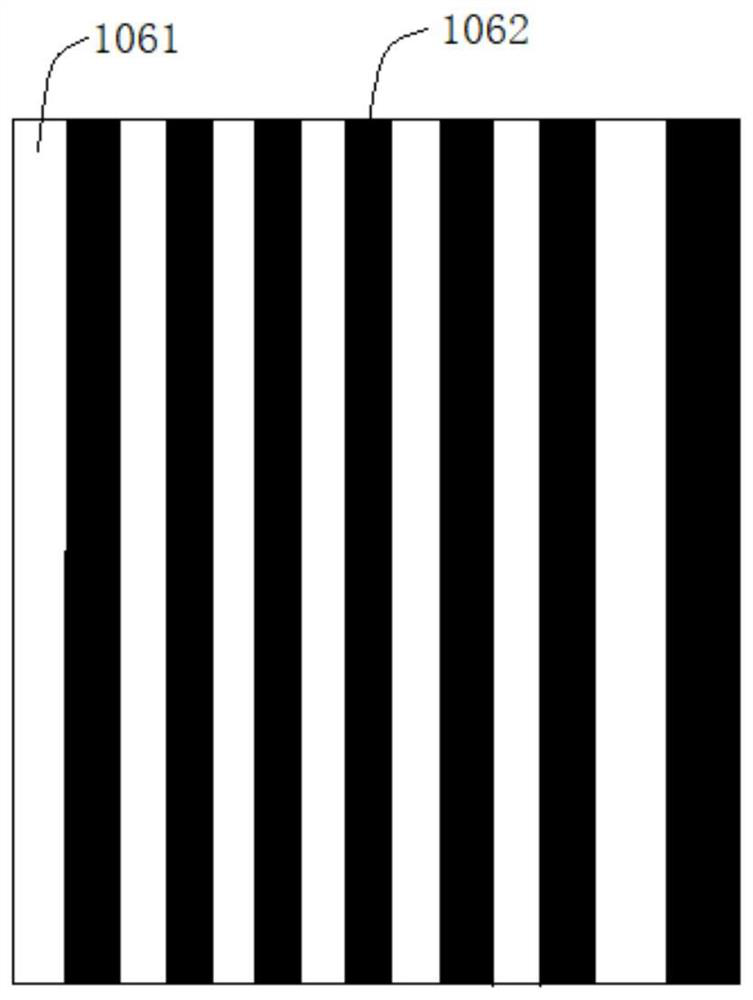

[0046] 4. Impurities are implanted through the photomask to form n-type doped regions 805, and combined with the epitaxial layer formed in the previous step to form p-type doped regions and n-type doped regions alternately arranged and distributed, and the plane of the doped thin layer Structural schematic reference image 3 , and the maximum width of the p-type doped region and the n-type doped region is 0.5 microns;

[0047] 5. The source electrode and P+ contact area of the device are formed by photolithography implantation;

[0048] 6. Grown the gate oxide layer by wet oxidation, deposited polysilicon, formed the gate by photolithography and etching thro...

Embodiment 2

[0051] Same as Example 1, the difference is that the planar structure schematic diagram of the doped thin layer refers to Figure 4 .

Embodiment 3

[0053] Same as Example 1, the difference is that the planar structure schematic diagram of the doped thin layer refers to Image 6 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Maximum width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com