Thermal battery positive electrode material with high performance and preparation method thereof

A positive electrode material, thermal battery technology, applied in the direction of primary battery electrode, battery electrode, active material electrode, etc., can solve the problem of poor wettability of the positive electrode active material of thermal battery, etc., to increase the active area of electrochemical reaction, improve the wettability Wetness, performance improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

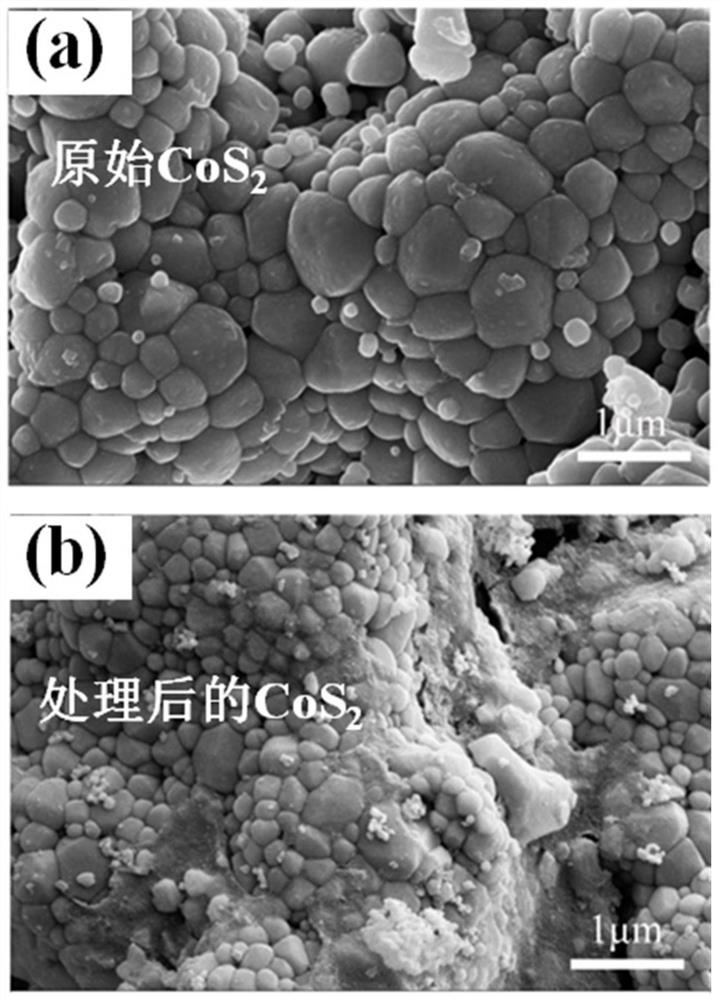

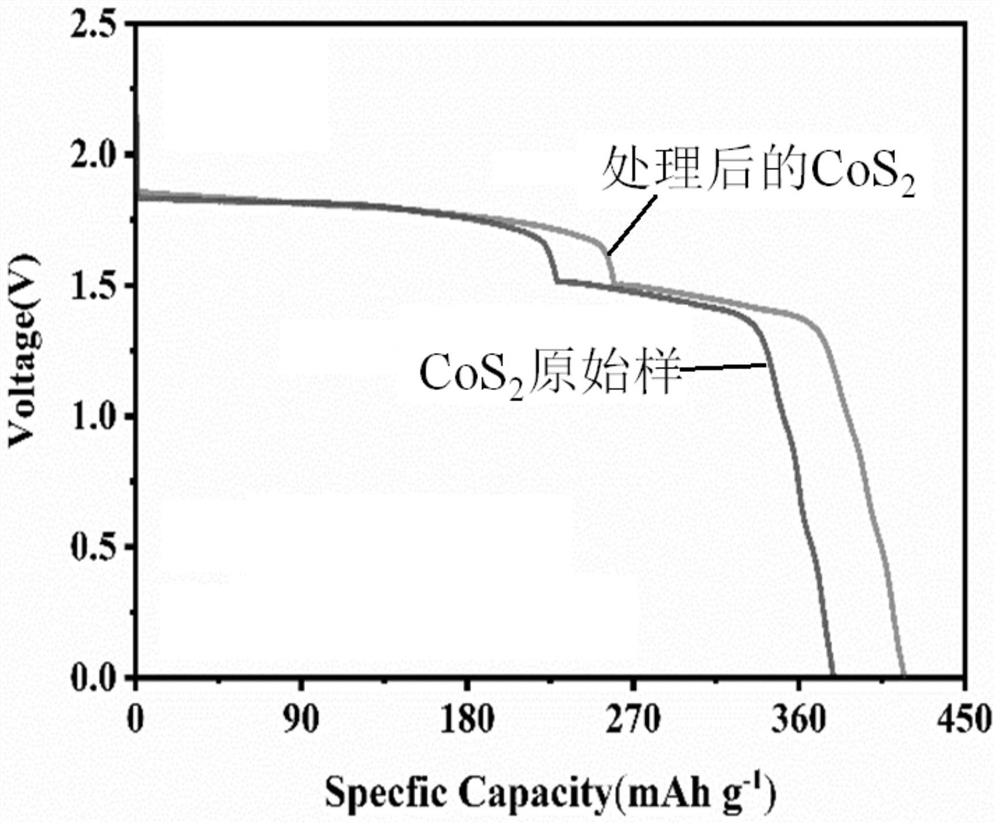

[0034] This embodiment provides a high-performance thermal battery CoS 2 A method for preparing positive electrode materials, including:

[0035] Preparation of precursor solution A: 0.15g Al(NO 3 ) 3 9H 2 O was added to 50ml of deionized water and kept stirring to form precursor solution A;

[0036] Preparation of precursor solution B: Add 0.2ml of ammonium hydroxide (22wt.%) to 50ml of deionized water, and stir evenly to form precursor solution B;

[0037] Preparation of suspension: 2g CoS 2 Add to precursor solution A, keep stirring, then slowly add precursor solution B to the system dropwise, and keep stirring to form a suspension;

[0038] Preparation of solid: Evaporate the suspension to dryness in a water bath at 80°C to obtain a solid, and transfer the solid to a vacuum oven at 80°C for 12 hours to remove water;

[0039] Calcination of solid: transfer the solid to a tube atmosphere furnace, and calcinate at 500°C for 3 hours in an argon atmosphere to prepare a th...

Embodiment 2

[0041] This embodiment provides a method for preparing a high-performance thermal battery CuO positive electrode material, including:

[0042] Preparation of precursor solution A: 0.128g Mg(NO 3 ) 2 ·6H 2 O was added to 50ml of deionized water and kept stirring to form precursor solution A;

[0043] Prepare precursor solution B: add 0.2g sodium hydroxide to 50ml deionized water, stir well to form precursor solution B;

[0044] Preparation of suspension: add 2g CuO to precursor solution A, continue to stir, then slowly add precursor solution B to the system dropwise, and continue to stir to form a suspension;

[0045] Preparation of solid: filter the suspension to obtain a solid, and transfer the solid to a vacuum oven at 80°C for 12 hours to remove moisture;

[0046] Calcination of the solid: Transfer the solid to an electric furnace and calcinate it at 500°C for 3 hours to prepare a high-performance thermal battery CuO cathode material.

Embodiment 3

[0048] This embodiment provides a high-performance thermal battery NiS 2 A method for preparing positive electrode materials, including:

[0049] Preparation of precursor solution A: 0.2688g Al(NO 3 ) 3 9H 2 O was added to 50ml of ethanol and continued to stir to form precursor solution A;

[0050] Preparation of precursor solution B: Add 0.0795g of ammonium fluoride to 50ml of ethanol to form precursor solution B;

[0051] Preparation of suspension: mix 2g NiS 2 Add to precursor solution B, keep stirring, then slowly add precursor solution A to the system dropwise, and keep stirring to form a suspension;

[0052] Preparation of solid: Evaporate the suspension to dryness in a water bath at 80°C to obtain a solid, and transfer the solid to a vacuum oven at 80°C for 12 hours to remove water;

[0053] Calcination of solid: Transfer the solid to an electric furnace and calcinate at 400°C for 3 hours to prepare a NiS thermal battery with high performance 2 Cathode material. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com