Thermal battery composite positive electrode material and preparation method thereof

A composite positive electrode material and a technology of positive electrode materials, which are applied in the field of thermal battery composite positive electrode materials and their preparation, can solve the problems of uneven mixing of positive electrode materials and conductive agents, low conductivity of thermal battery positive electrode materials, etc., and achieve easy acquisition and improved discharge The effect of performance, broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A high electrical and thermal conductivity battery VO 2 A method for preparing a composite cathode material, the specific steps comprising:

[0035] Preparation of reducing solution A: 0.5g C 6 h 12 o 6 Add 5ml of concentrated nitric acid to a mixed solution of 100ml of water and ethanol (the mass ratio of water to ethanol is 1:1), stir evenly to form reducing solution A;

[0036] Preparation of Ag-containing precursor solution B: 1g AgNO 3 Add to 100ml aqueous solution, continue to add ammonia water until the Ag precursor solution becomes clear, and obtain the Ag precursor solution B;

[0037] 1g VO 2 Add to reducing solution A, stir and mix to obtain suspension C;

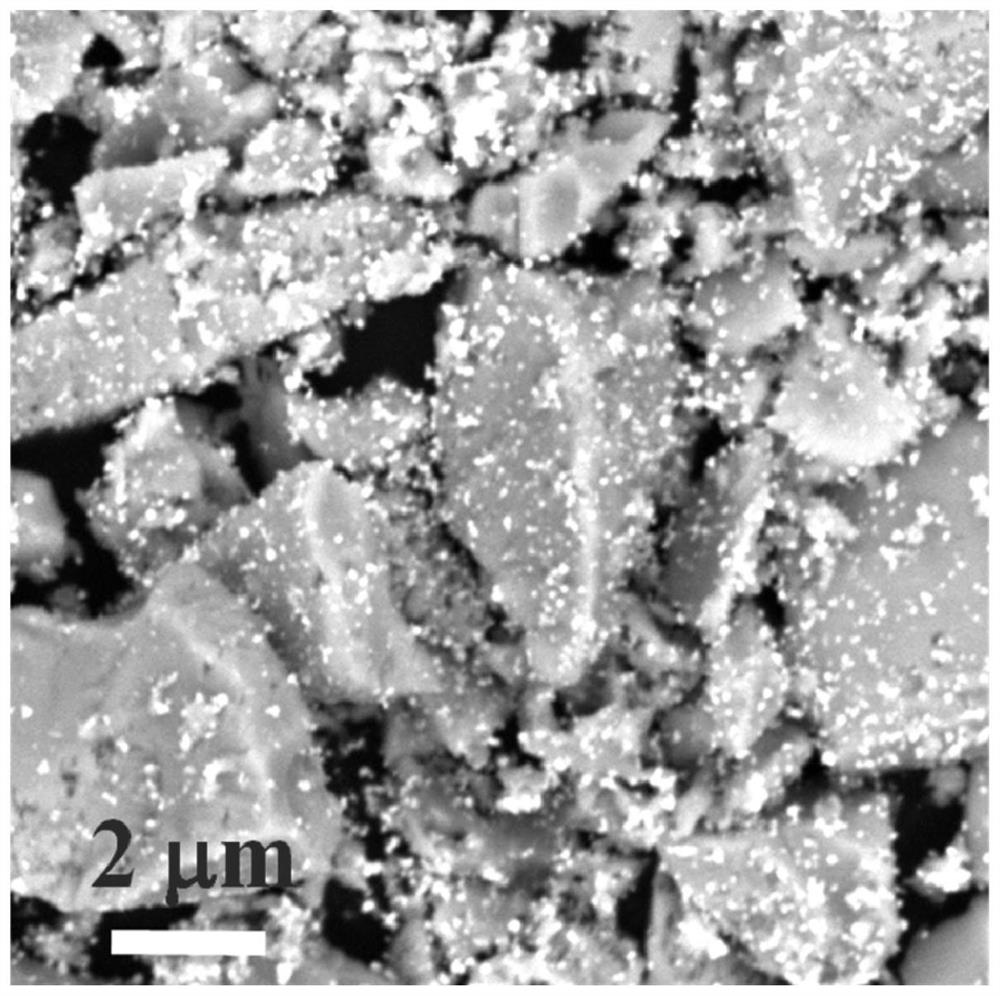

[0038] Add the Ag precursor solution B to the reducing solution A at a mass ratio of 1:2, slowly add it to the suspension C, stir and mix, so that the surface of the positive electrode material can generate nano-silver in situ, and dry to remove the solvent Fabricated thermal battery VO with high co...

Embodiment 2

[0040] A high electrical and thermal conductivity battery FeS 2 A method for preparing a composite cathode material, the specific steps comprising:

[0041]Preparation of reducing solution A: Add 2 g of ascorbic acid and 10 ml of concentrated sulfuric acid to a mixed solution of 100 ml of water and glycerol (the mass ratio of water to glycerol is 3:1), and stir evenly to form reducing solution A;

[0042] Preparation of Ag-containing precursor solution B: 1g Ag 2 SO 4 Add to 100ml aqueous solution, continue to add ammonia water until the Ag precursor solution becomes clear, and obtain the Ag precursor solution B;

[0043] 2g FeS 2 Add to reducing solution A, stir and mix to obtain suspension C;

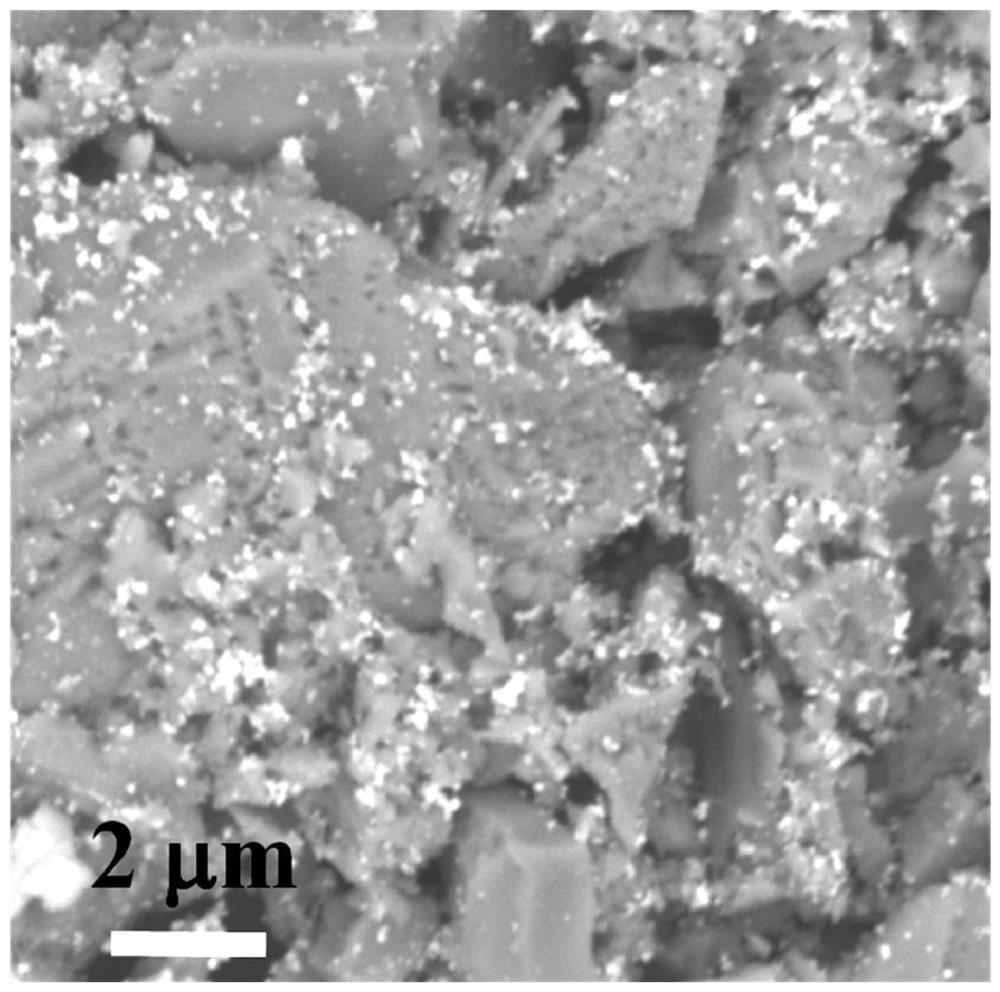

[0044] Add the Ag precursor solution B to the reducing solution A at a mass ratio of 1:4, slowly add it to the suspension C, stir and mix, so that the surface of the positive electrode material can generate nano-silver in situ, and dry to remove the solvent Fabrication of thermal...

Embodiment 3

[0047] FeF battery with high electrical and thermal conductivity 3 A method for preparing a composite cathode material, the specific steps comprising:

[0048] Preparation of reducing solution A: mix 2g sodium tartrate and 10ml H 3 PO 4 Add it to a mixed solution of 100ml of water and glycerin ether (the mass ratio of water to glycerol is 2:1), stir evenly to form reducing solution A;

[0049] Preparation of Ag-containing precursor solution B: 1g AgNO 3 Add to 100ml aqueous solution, continue to add ammonia water until the Ag precursor solution becomes clear, and obtain the Ag precursor solution B;

[0050] FeF 3 Adding to Ag-containing precursor solution B, stirring and mixing to obtain suspension C;

[0051] Slowly add the reducing solution A to the suspension C at a mass ratio of 1:3 to the Ag-containing precursor solution B, stir and mix, so that the surface of the positive electrode material can generate nano-silver in situ, and dry to remove the solvent Fabricated ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap