Recyclable castor oil-based unsaturated polyester Vitrimer material based on dynamic disulfide bond and preparation method of recyclable castor oil-based unsaturated polyester Vitrimer material

A castor oil-based, disulfide bond technology, applied in the field of Vitrimer materials, can solve the problems of unsustainable recycling and reuse of thermoplastic materials such as mechanical properties, and achieve the effect of sustainable recycling, high yield and abundant resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

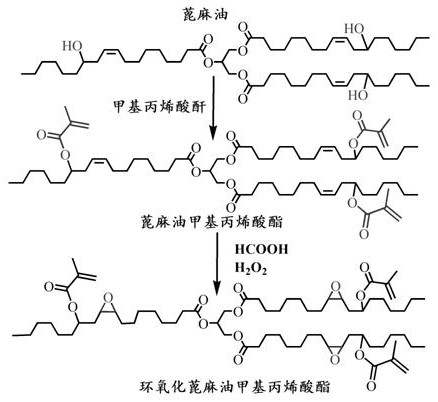

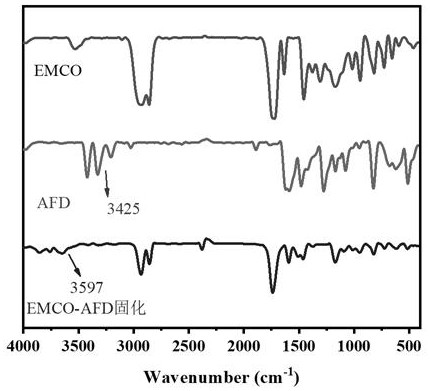

[0035] A kind of preparation method based on the recyclable castor oil base unsaturated polyester Vitrimer material of dynamic disulfide bond, is characterized in that, comprises the following steps:

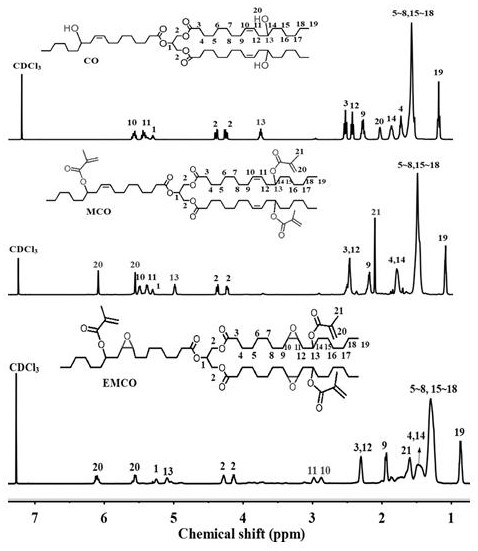

[0036] Step 1: Preparation of methacrylated castor oil

[0037] Mix and stir 1 part of castor oil, 3-4 parts of triethylamine and 0.01-0.05 parts of catalyst 4-dimethylaminopyridine at 25 °C for 0.5-1 h; then pass inert gas into the sealed system, and slowly Add 3-4 parts of methacrylic anhydride dropwise. After the dropwise addition, the reaction system is heated up to 45 °C and kept warm for 20-24 h; after the reaction, first extract with dichloromethane, and then separate the organic phase Wash with saturated sodium bicarbonate solution, 0.5-1 mol / L NaOH, 0.5-1 mol / L HCl, and saturated brine; finally dry with anhydrous magnesium sulfate, filter with suction, and remove dichloromethane by rotary evaporation under reduced pressure, namely This gives castor oil methacrylate.

[...

Embodiment 1

[0045] Preparation of a recyclable castor oil-based unsaturated polyester Vitrimer material based on dynamic disulfide bonds:

[0046] Step 1: Preparation of methacrylated castor oil

[0047] Mix and stir 1 part of castor oil, 3 parts of triethylamine and 0.02 parts of catalyst 4-dimethylaminopyridine at 25 °C for 0.5 h; then pass argon gas into the closed system, and slowly add 3 parts of methyl Acrylic anhydride, after the dropwise addition, make the reaction system warm up to 45 ° C and keep the temperature for 20 h; / L NaOH, 0.5 mol / L HCl, and saturated saline for washing; finally, dry over anhydrous magnesium sulfate, filter with suction, and rotary evaporate under reduced pressure to remove dichloromethane to obtain castor oil methacrylate.

[0048] Step 2: Synthesis of epoxidized methacrylate castor oil

[0049] Mix 1 part of methacrylate castor oil synthesized in Step 1 and 6 parts of formic acid into a three-necked flask equipped with a stirring device, and stir at ...

Embodiment 2

[0053] Preparation of a recyclable castor oil-based unsaturated polyester Vitrimer material based on dynamic disulfide bonds:

[0054] Step 1: Preparation of methacrylated castor oil

[0055] 1 part of castor oil, 3.5 parts of triethylamine and 0.03 parts of catalyst 4-dimethylaminopyridine were mixed and stirred for 0.5 h at 25 °C; then argon gas was introduced into the closed system, and 3.5 parts of methacrylic acid was slowly added dropwise anhydride, after the dropwise addition, the reaction system was warmed up to 45 °C and kept warm for 22 h; after the reaction was finished, the initial product was first extracted with dichloromethane, and then the organic phase was respectively washed with saturated sodium bicarbonate solution, 0.5 mol / Wash with L NaOH, 0.5 mol / L HCl, and saturated brine; finally dry with anhydrous magnesium sulfate, filter with suction, and rotary evaporate under reduced pressure to remove dichloromethane to obtain methacrylate castor oil.

[0056] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com