Preparation method of rubber paint containing epoxidized gutta-percha

A technology of eucommia rubber and epoxidation, which is applied in epoxy resin coatings, rubber derivative coatings, anti-corrosion coatings, etc., can solve the problems of poor aging resistance, low solubility, and large amount of solvents, and achieve resource shortage and corrosion resistance Good performance and improved corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The preparation of epoxidized eucommia rubber, the preparation route is as follows:

[0028]

Embodiment 1

[0030] Add 5g EUG and 70ml petroleum ether into a 250ml container equipped with a stirrer, thermometer and constant pressure funnel, heat to 50°C and start stirring. After the EUG is completely dissolved, add 40ml of distilled water dropwise at a fixed rate for 30min, stir for 2h, and then add Add 2.5ml of formic acid, add 15ml of hydrogen peroxide dropwise at a rate of 1ml / min, stir at 50°C for 2h, wash EEUG with alcohol until neutral. Dry to constant weight in a vacuum oven at room temperature, and the epoxy degree measured after drying is 21.1%.

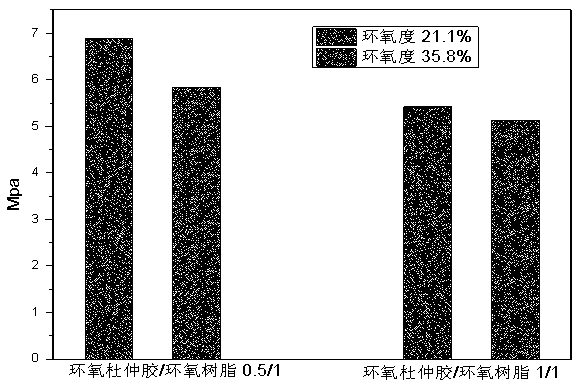

[0031] Dissolve 1g of epoxidized eucommia rubber in 20ml of ethyl acetate, heat and stir in a water bath, then dissolve 2g of epoxy resin in 5ml of ethyl acetate, heat and stir in a water bath, and finally add 1.5 g curing agent and 0.03g defoaming agent, stir evenly to coat the board to cure and test the performance of the coating.

Embodiment 2

[0033] Add 10g EUG and 140ml petroleum ether into a 500ml container equipped with a stirrer, thermometer and constant pressure funnel, heat to 55°C and start stirring. After the EUG is completely dissolved, add 80ml of distilled water dropwise at a fixed rate for 30min, stir for 2h, then add 5ml of formic acid, 30ml of hydrogen peroxide was added dropwise at a rate of 1ml / min, stirred at 55°C for 2h, and the EEUG was washed with alcohol until neutral. Dry to constant weight in a vacuum drying oven at room temperature, and the epoxy degree measured after drying is 35.8%.

[0034] Dissolve 1g of epoxidized eucommia rubber in 25ml of chloroform, heat and stir in a water bath, then dissolve 1g of epoxy resin in 5ml of ethyl acetate, heat and stir in a water bath, and finally add 1g of curing agent and 0.02g defoamer, stir evenly to coat the board to cure and test the performance of the coating.

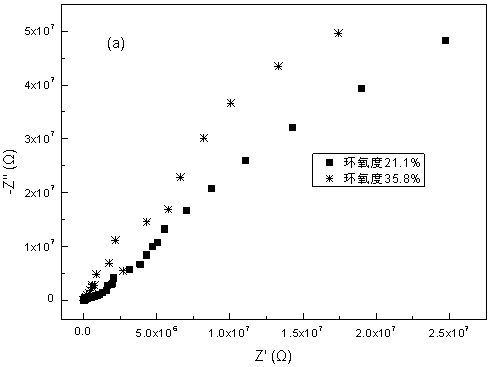

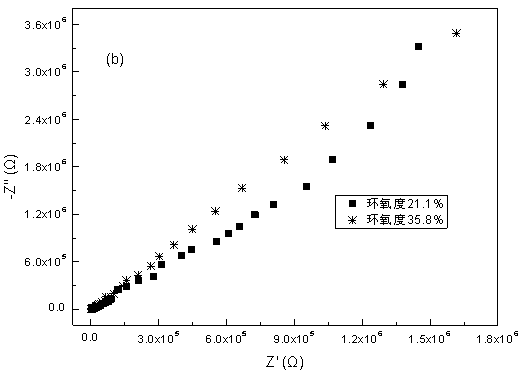

[0035] Figure 1 is the electrochemical analysis diagram of different epoxy degrees u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com