A non-damaging circulation culture device for salina

A cyclic culture, non-destructive technology, applied in biochemical cleaning devices, enzymology/microbiology devices, single-cell algae, etc., can solve problems such as cell damage, increase equipment energy consumption, and reduce pollutants and solubility. Oxygen, the effect of increasing dissolved carbon dioxide

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

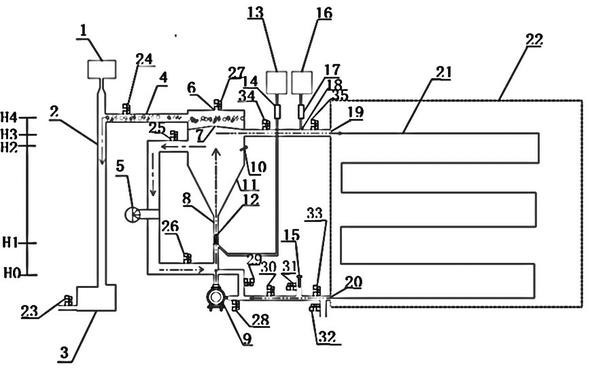

[0040] Embodiment 1 The cultivation method relying on this cultivation device is as follows: cleaning the closed flat-plate photobioreactor 21 with a total volume of 900L. The total volume of the device is 100L. Fill the above-mentioned device with a sodium hypochlorite solution with a concentration of 200ppm, turn on the centrifugal pump 9, fully disinfect it for 5 hours, and drain it; rinse it once with well water, turn on the air compressor 13, and adjust the flow meter 5 to 10L / min. Drain after fully aerating for 5 hours. Use a submersible pump to pump 900L of natural seawater with a salinity of 30‰, add 54Kg of NaCl, mix well, measure its salinity to 90‰, add KNO 3 450g, 27g KH 2 PO 4 , 1080gMgSO 4 , 360g NaHCO 3 , and about 18 mL of concentrated hydrochloric acid solution was added to adjust the pH to 8.10. The above nutrient solution was fully mixed and filtered through a 0.22 μm pore size filter. Close the negative pressure air extractor 1, the second valve 25, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com