Application of Neofomitella fumosipora Han in laccase production and laccase production method from Neofomitella fumosipora Han

The technology of layer-porous bacteria and gray-porous bacteria is applied in the application of new microporous layer-porous bacteria in the field of laccase production and its induction and acceleration of laccase production, which can solve the problem of complex fermentation substrate components, shortening laccase production cycle, and lacquer production. The problem of high cost of enzyme production, to achieve the effect of convenient purification and utilization, shortening the production cycle, and conducive to environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] 1. Experimental strains

[0051] Neofomitella fumosipora Han 386 was provided by the North China Forestry Experimental Center of the Chinese Academy of Forestry and is now preserved in the College of Life Sciences, Langfang Teachers College.

[0052] The above-mentioned bacterial strain of the present invention is provided by the North China Forestry Experimental Center of the Chinese Academy of Forestry Sciences, and its strain number is HFNC 851 in the North China Forestry Experimental Center Herbarium of the Chinese Academy of Forestry Sciences, and its preservation address is No. 1, Shuizha West Road, Mentougou District, Beijing.

[0053] 2. Medium

[0054] Malt extract agar medium (Malt extract agar, MEA): glucose 10g, malt extract powder 20g, potassium dihydrogen phosphate 3g, agar 20g, water to 1L.

[0055] Complete Yeast Medium (CYM): glucose 20g, peptone 2g, yeast extract powder 2g, magnesium sulfate heptahydrate 0.5g, dipotassium hydrogen phosphate trihydrate...

Embodiment 2

[0064] 2-1), N.fumosipora Han 386 provided by the North China Forestry Experimental Center of the Chinese Academy of Forestry and stored on the malt extract powder agar medium MEA was inoculated into solid complete medium (CYM plate Complete culture medium), under the condition of 26±0.5°C (usually 25-28°C), constant temperature culture for 8 days (usually 7-9 days), and strain activation treatment;

[0065] 2-2), use a sterile puncher to punch the activated culture of the strain after 8 days of activation culture, and obtain an expanded culture inoculum with a diameter of 5 mm; then, under aseptic conditions, inoculate the expanded culture inoculum to In the liquid complete medium, wherein in every 100mL liquid complete medium, inoculate 5 described expansion culture inoculums; Then carry out dark liquid expansion culture on the shaker, obtain the expansion culture mixture (containing expansion Cultivate to obtain gray hole new small layer hole mycelium ball); wherein the cul...

Embodiment 3

[0079] In addition to the corresponding Beijing poplar wood powder, Chinese toon wood powder, and weeping willow wood powder in medium 1 (T1), medium 2 (T2), medium 3 (T3) and medium 4 (T4) in steps 2-4) , The consumption of sorghum stalk powder is respectively except 2g, and all the other are identical with embodiment 2.

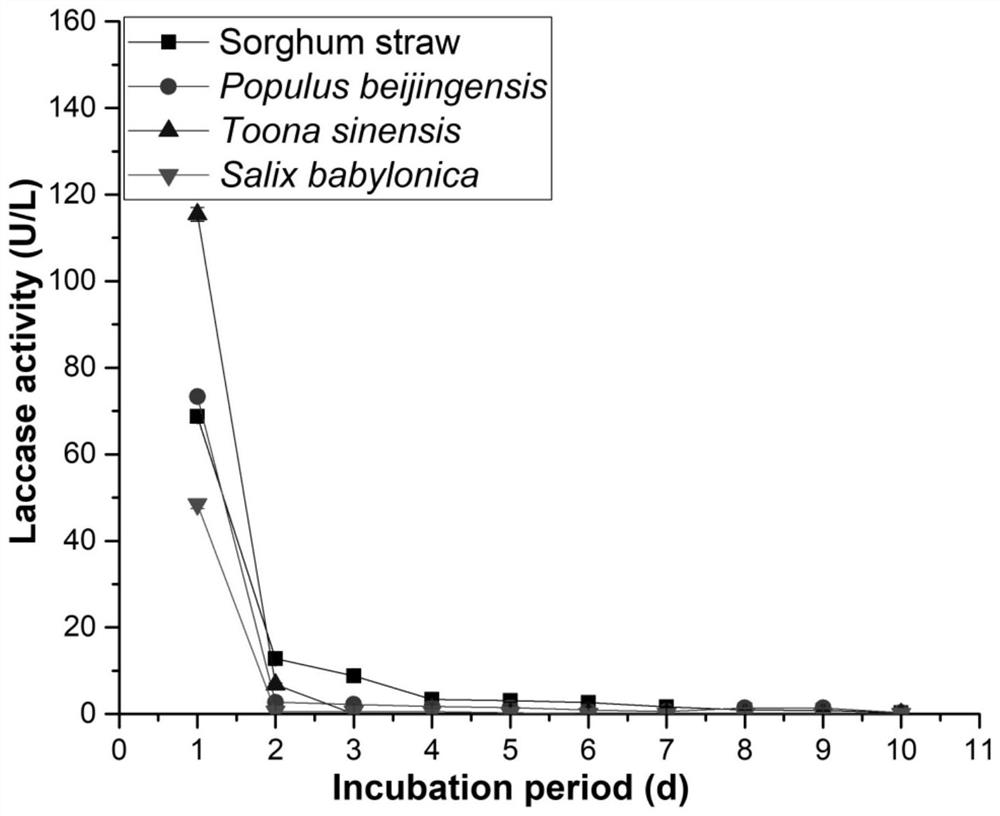

[0080] The laccase activity measurement result shows: Neofomitella fumosipora Han 386 of the present invention uses the culture medium of the present invention as the culture medium to induce culture, all just can reach maximum production laccase activity on the 1st day, and T2 culture medium The activity of producing laccase in the culture medium containing Toona sinensis wood flour was higher than that in culture medium T1, T3 and T4.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com