Method for recovering iron from semi-molten reduction cold rolling sludge

A sludge and molten state technology is applied in the field of low-temperature recovery of metal iron in cold-rolled sludge, which can solve the problem of high utilization and energy consumption of metal iron, and achieve the effects of protecting the environment, suitable for popularization and use, and simple and easy to implement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

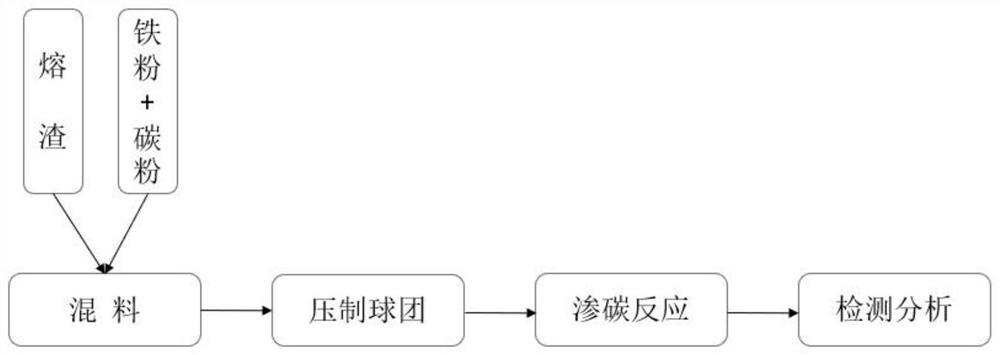

[0032] In this embodiment, a method for reclaiming iron from semi-molten reducing cold rolling sludge comprises the following steps:

[0033] a. Sludge pretreatment and semi-molten carburizing process:

[0034] According to the ratio of reducible oxygen and carbon in the mixture of cold-rolled sludge and carbon powder is 1:1.2, the cold-rolled sludge is mixed with carbon powder, and the mixing components are adjusted to obtain cold-rolled sludge and carbon. Powder mixture, and then the mixture is pressed into blocks, and then put into the heating furnace for semi-molten carburizing;

[0035] Before starting to heat up, argon gas is introduced into the furnace to drive away the air inside the furnace, the flow rate of argon gas is controlled to 1L / min, and the heating rate is 5°C / min. And pass inert gas protection into the furnace, carry out semi-molten state carburization, obtain semi-molten state mixture, complete the carburization process; this embodiment is under the same ...

Embodiment 2

[0046] In this example, when mixing materials, the slag-forming components are added in advance according to the mass ratio of the slag-forming main components when the prepared iron-containing cold-rolled sludge lump ore is smelted and reduced in the step c. Raw material, mixed with cold mill sludge and carbon powder to form a mixture:

[0047] Table 1 selects the composition of synthetic slag

[0048]

[0049] Experimental test analysis:

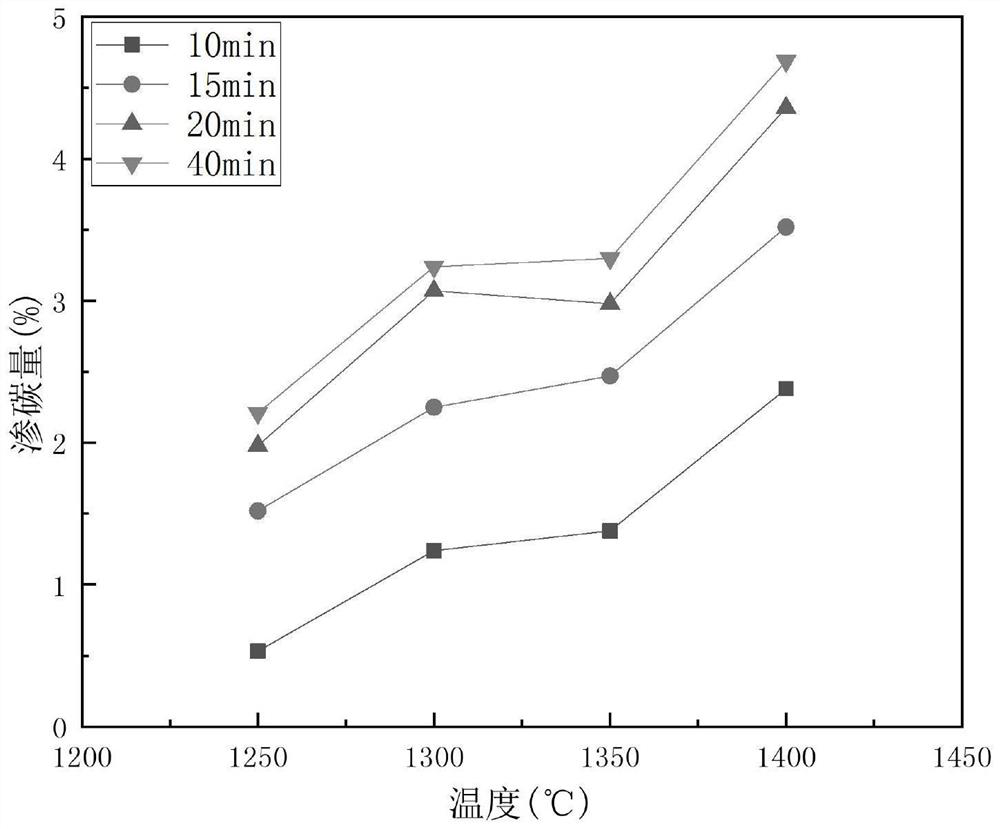

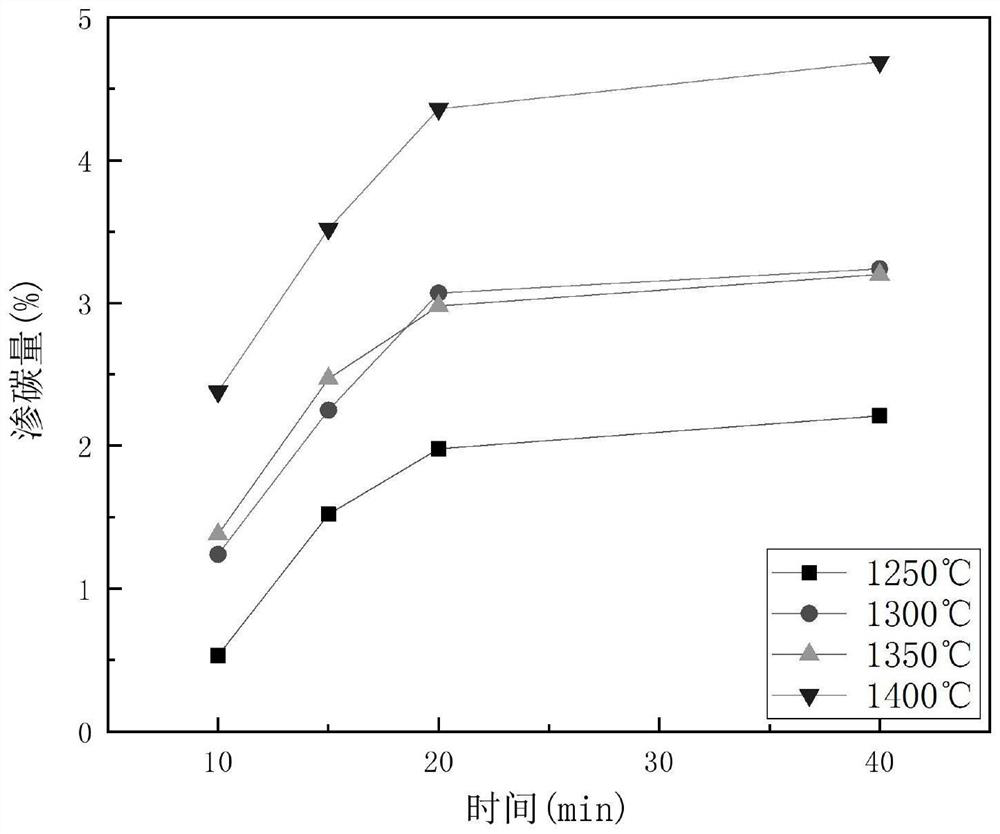

[0050] By testing the influence of the liquid phase fraction of molten slag on the carburizing amount of metal particles, the influence of the melting degree of slag phase on the carburizing of metal particles inside the pellets was analyzed, and the reduction carburizing experiment of pellets with different slag phase compositions was carried out. By calculating the phase transformation melting curves of different eutectic points in the phase diagram, three slag phases with different melting degrees in the same slag system were select...

Embodiment 3

[0054] In this embodiment, the mass percentage of iron contained in the cold rolling sludge used is not less than 50wt%. Selecting sludge with higher iron content as semi-molten carburizing has the combined effect of economical efficiency, iron resource recovery and comprehensive environmental management benefit maximization. Thereby amplifying the demand of industrialization and realizing the practical application of this technology.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com