Cordierite microcrystal powder and preparation method thereof, aluminum oxide ceramic substrate and preparation method thereof

A technology of alumina ceramics and micro-alumina, applied in the direction of aluminum silicate, silicate, etc., can solve the problems of inability to promote the development of alumina plate crystals in the substrate, the mechanical properties of the substrate are not promoted, and the density is low. Achieve the effect of reducing dielectric constant, short holding time, sintering temperature and sintering time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

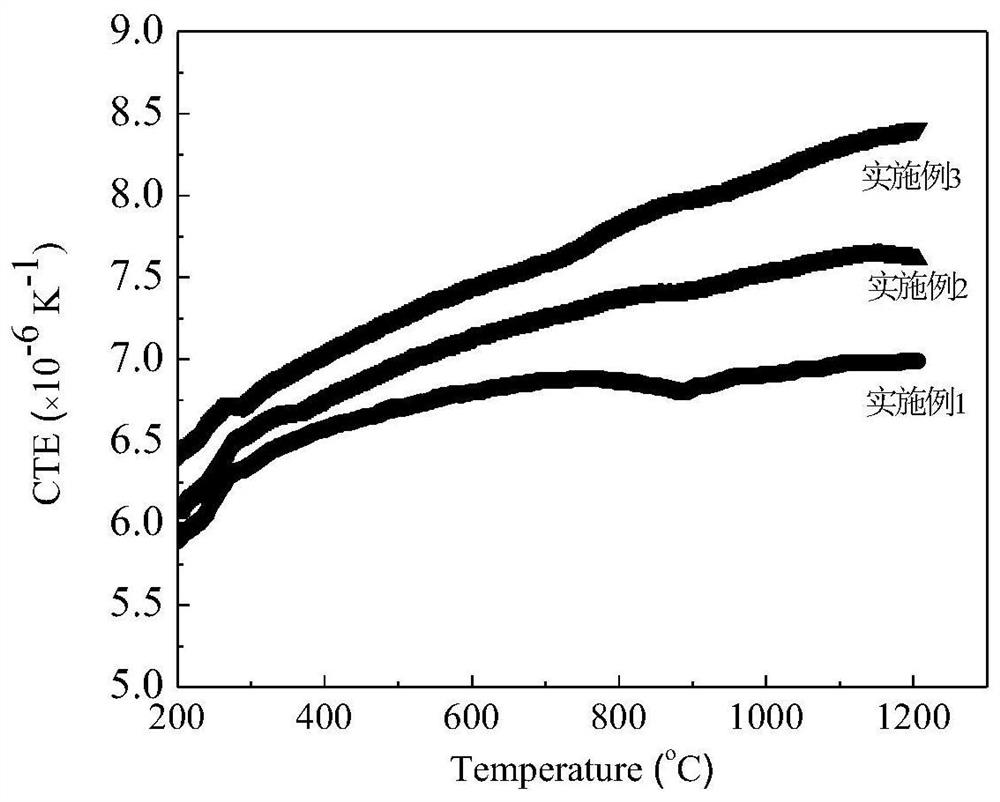

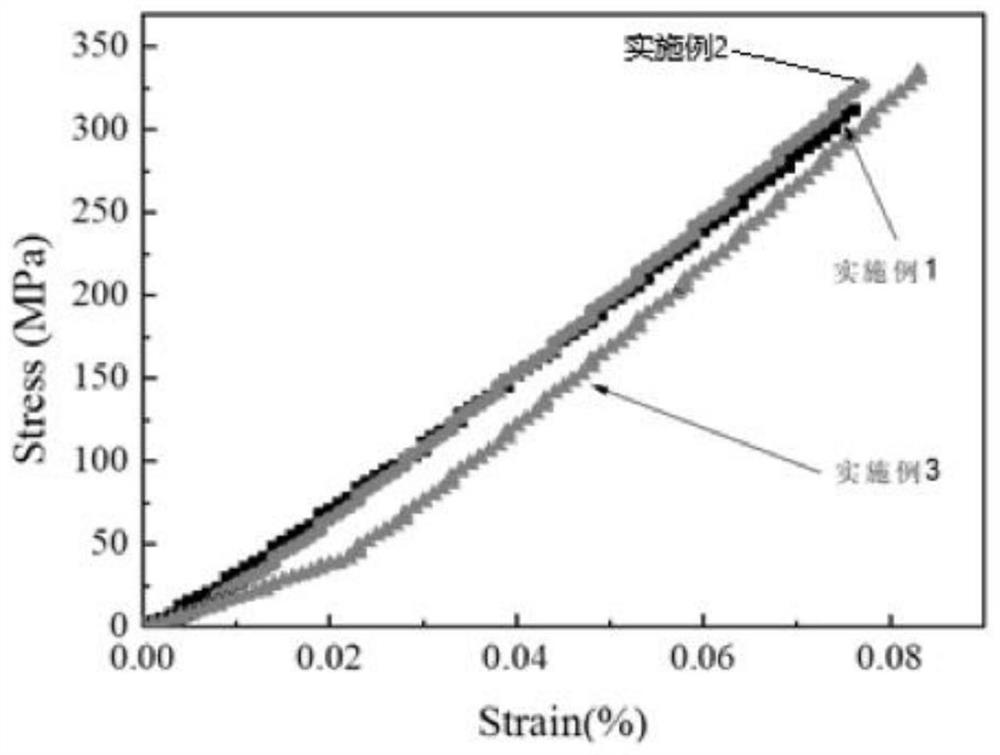

Embodiment 1

[0049] A low-temperature sintered ultra-thin alumina ceramic substrate with adjustable dielectric constant, low dielectric loss and thermal expansion coefficient, and high strength, and a preparation method thereof, comprising the following steps:

[0050] (1) Raw material preparation and drying: After drying the used powder at 80°C for 24 hours, weigh 14 g of micron magnesium oxide (μm-MgO), micron silicon oxide (μm-SiO 2 )51g, micron alumina (μm-Al 2 o 3 ) 910g, CaO powder 20g, ZnO powder 5g.

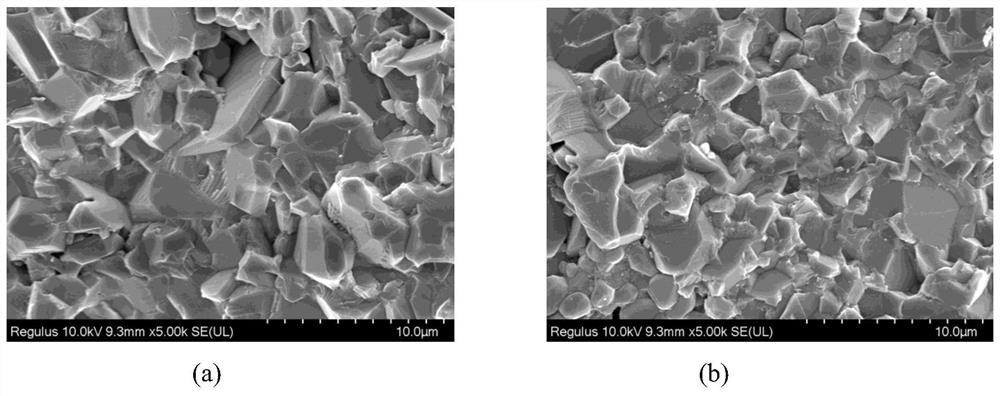

[0051] (2) Pre-synthesis of cordierite microcrystalline powder: 14 g of μm-MgO, μm-SiO 2 51g and μm-Al 2 o 3 Add 35g into the ball mill tank, use water as the medium, corundum balls as the abrasive, the ball milling time is 30h, and the ball mill speed is 400r·min -1 , the slurry was dried at 90°C for 48h, and then in a box furnace at 4°C·mim -1 Raise to 1050°C for 4 hours, then cool in the furnace to obtain cordierite microcrystalline powder;

[0052] (3) Slurry preparation:...

Embodiment 2

[0057] A low-temperature sintered ultra-thin alumina ceramic substrate with adjustable dielectric constant, low dielectric loss and thermal expansion coefficient, and high strength, and a preparation method thereof, comprising the following steps:

[0058] (1) Raw material preparation and drying: After drying the used powder at 80°C for 24 hours, weigh 11.2g of μm-MgO, μm-SiO 2 40.8g, μm-Al 2 o 3 898g, CaO powder 40g, ZnO powder 10g.

[0059] (2) Pre-synthesis of cordierite microcrystalline powder: 11.2g of μm-MgO, μm-SiO 2 40.8g and μm-Al 2 o 3 Add 28g into the ball mill tank, use water as the medium, corundum balls as the abrasive, the ball milling time is 30h, and the ball mill speed is 400rpm min -1 , the slurry was dried at 90°C for 48h, and then in a box furnace at 4°C·mim -1 Raise it to 1100°C for 2 hours, and then cool it in the furnace to obtain cordierite microcrystalline powder;

[0060] (3) Slurry preparation: the obtained cordierite microcrystal powder,...

Embodiment 3

[0065] A low-temperature sintered ultra-thin alumina ceramic substrate with adjustable dielectric constant, low dielectric loss and thermal expansion coefficient, and high strength, and a preparation method thereof, comprising the following steps:

[0066] (1) Raw material preparation and drying: After drying the used powder at 80°C for 24 hours, weigh 7g of μm-MgO and μm-SiO 2 25.5g, μm-Al 2 o 3 892.5g, CaO powder 60g, ZnO powder 15g.

[0067] (2) Pre-synthesis of cordierite microcrystalline powder: 7g of μm-MgO, μm-SiO 2 25.5g and μm-Al 2 o 3 Add 17.5g into the ball mill tank, use water as the medium, corundum balls as the abrasive, the ball milling time is 30h, and the ball mill speed is 400rpm min -1 , the slurry was dried at 90°C for 48h, and then in a box furnace at 4°C·mim -1 Raise to 1150°C for 1.5 hours, then cool in the furnace to obtain cordierite microcrystalline powder;

[0068] (3) Slurry preparation: the obtained cordierite microcrystal powder, the rem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap