Method for preparing nano iron and oxide thereof by taking sintered ash as raw material

A nano-iron oxide and sintered ash technology, which is applied in ferrous oxide, iron oxide, nanotechnology and other directions, can solve the problems of inability to remove harmful elements, affect the normal production of blast furnaces, waste resources and the environment, and achieve simple reaction equipment. Easy to control, low cost, water saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

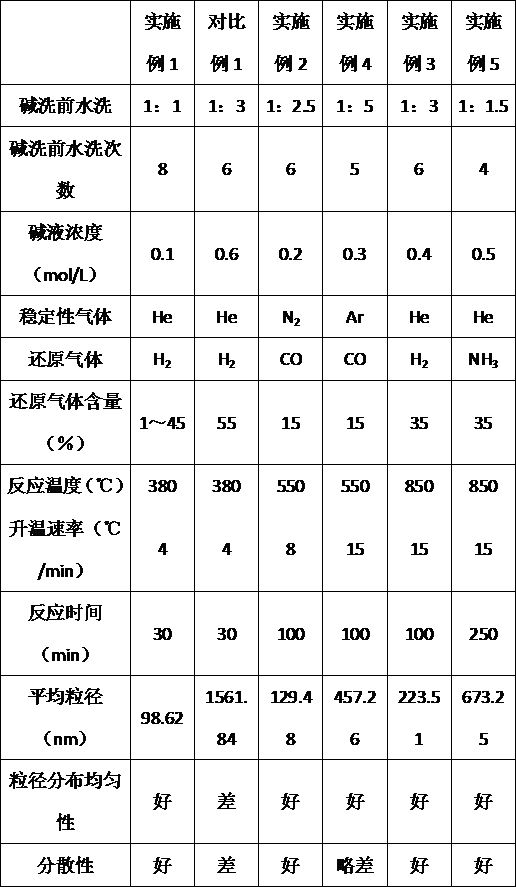

Embodiment 1

[0022] A method for preparing nano ferric oxide by using sintered ash as raw material, the specific operation steps are:

[0023] 1) Take 80g of sintered ash, wash it 8 times with deionized water according to the ratio of 1:1, use electromagnetic to select iron oxide for each cleaning, and mix the solid substances separated by magnetic each time to obtain primary solid substances;

[0024] 2) Wash the primary solid material obtained in step 1) again with deionized water, and perform magnetic separation again after cleaning, measure the conductivity of the remaining water after magnetic separation, and retain the solid material for secondary magnetic separation;

[0025] 3) Repeat step 2) for the second magnetic separation solid material until the conductivity is stable (the conductivity is the same as or close to the conductivity of the deionized water used), and the primary purified solid material is obtained;

[0026] 4) The primary purified solid material prepared in step 3...

Embodiment 2

[0031] A method for preparing nano ferrous oxide with sintered ash as raw material, the specific operation steps are:

[0032] 1) Take 80g of sintered ash, wash it 6 times with deionized water according to the ratio of 1:2.5, use electromagnetic to select iron oxide for each cleaning, and mix the solid substances separated by magnetic separation each time to obtain primary solid substances;

[0033] 2) Wash the primary solid material obtained in step 1) again with deionized water, and perform magnetic separation again after cleaning, measure the conductivity of the remaining water after magnetic separation, and retain the solid material for secondary magnetic separation;

[0034] 3) Repeat step 2) for the second magnetic separation solid material until the conductivity is stable (the conductivity is the same as or close to the conductivity of the deionized water used), and the primary purified solid material is obtained;

[0035] 4) The primary purified solid material prepared...

Embodiment 3

[0040] A method for preparing nano-iron with sintered ash as raw material, the specific operation steps are:

[0041] 1) Take 80g of sintered ash, wash it 6 times with deionized water according to the ratio of 1:3, use electromagnetic to select iron oxide for each cleaning, and mix the solid substances separated by magnetic each time to obtain primary solid substances;

[0042] 2) Wash the primary solid material obtained in step 1) again with deionized water, and perform magnetic separation again after cleaning, measure the conductivity of the remaining water after magnetic separation, and retain the solid material for secondary magnetic separation;

[0043] 3) Repeat step 2) for the second magnetic separation solid material until the conductivity is stable (the conductivity is the same as or close to the conductivity of the deionized water used), and the primary purified solid material is obtained;

[0044] 4) The primary purified solid material prepared in step 3) is subject...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com