Preparation method and application of bionic silicified collagen material

A technology of silicified gel and raw materials, applied in the direction of prosthesis, medical science, etc., can solve the problems of limiting the industrial application of biomimetic silicified collagen materials, dose-dependent toxicity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

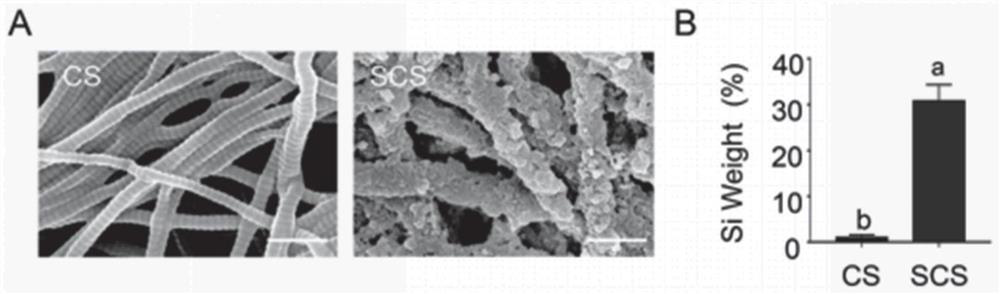

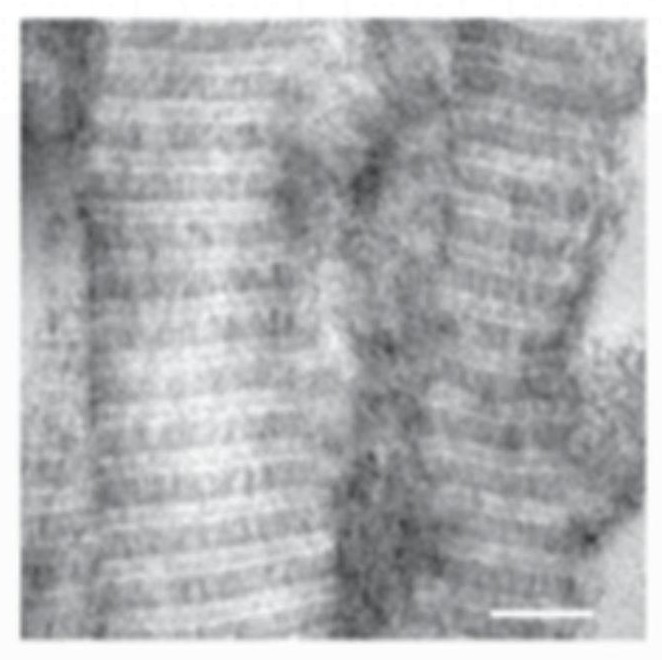

[0031] Example 1: Preparation of biomimetic siliconized collagen material

[0032] Mix Silbond 40, absolute ethanol, deionized water and 37% hydrochloric acid (pH regulator) at room temperature according to the molar ratio of 1.875:396.79:12.03:0.0218 (mass ratio is 15:182.8:2.167:0.008) to obtain the volume percentage 3% orthosilicic acid solution;

[0033] Mix the above-mentioned 3% orthosilicic acid solution with 36mM (choline chloride, molecular weight: 139.62; Sigma-Aldrich, St.Louis, MO, USA) in equal volumes to prepare a pretreatment solution, and determine the pH value of the pretreatment solution Adjusted to 5.5, the concentration of orthosilicic acid adjusted to 1.5% by volume;

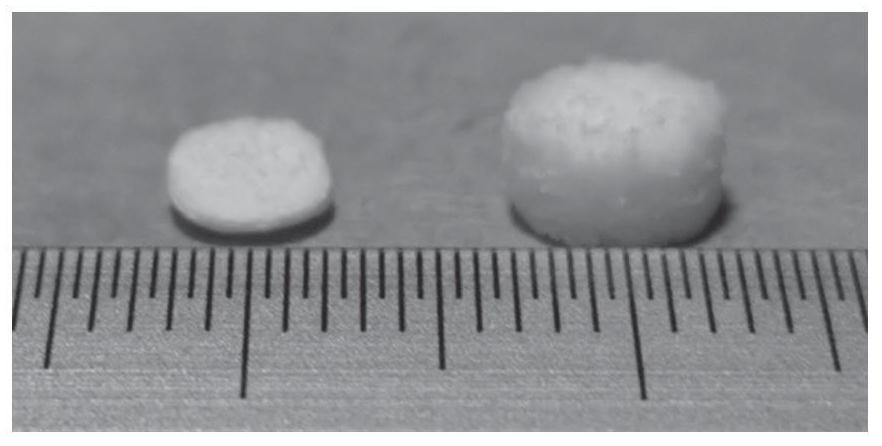

[0034] Trim the three-dimensionally restructured type I collagen sponge (ACE collagen, Ace Surgical Supply Co., Inc, MA, USA) into a collagen block with a diameter of 0.3 cm, rinse it with Milli-Q deionized water three times and set aside;

[0035] The four schemes shown in Table 1 were us...

Embodiment 2

[0061] Example 2: Effects of Silicified Collagen Scaffold Extraction on the Morphology and Neuropeptide Expression of Dorsal Root Ganglion Cells

[0062] 2.1 Preparation of biomimetic siliconized collagen scaffold extract

[0063] According to the method 1.4 in Example 1, soak the dried biomimetic siliconized collagen scaffold (100mg) in 10ml Tris hydrochloric acid buffer solution (PH=7.4) at 37°C, take out the material after 24 hours, and collect the buffer solution;

[0064] The above-mentioned buffer solution was mixed with Neurobasal complete medium containing 20ng / mL nerve growth factor (R&D Systems, Minneapolis, MN, USA) according to a ratio of 1:2, and used as an extract medium for the cultivation of dorsal root ganglion cells ( extract group), and the dorsal root ganglion cells of the control group were cultured with Neurobasal complete medium containing 20ng / mL nerve growth factor (control group). The Neurobasal-A complete medium configuration method is to add 0.5mM / ...

Embodiment 3

[0097] Example 3: Effects of Silicic Acid on Morphology and Neuropeptide Expression of Dorsal Root Ganglion Cells

[0098] 3.1 Isolation and culture of dorsal root ganglion cells

[0099] With embodiment 2.

[0100] 3.2 Immunofluorescence staining experiment

[0101] In order to investigate the effect of silicic acid stimulation on DRG cells, dilute an appropriate amount of sodium orthosilicate in the complete medium to prepare fresh silicon-containing medium, and the final silicon concentration is between 5 μM and 40 μM; the isolated DRG Ganglion cells were inoculated on cell slides in a 24-well plate, cultured in different concentrations of silicon-containing medium for 3 days, and immunofluorescent staining experiments were performed; the specific method was the same as in Example 2;

[0102] 3.3 Determination of the effect of silicic acid on the morphology of dorsal root ganglion cells

[0103] After the dorsal root ganglion cells were cultured in 5, 10, 20, and 40 μM s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com