Film-coated proppant and preparation method thereof

A proppant and film coating technology, applied in chemical instruments and methods, earth-moving drilling, wellbore/well components, etc., can solve the problems of low gas production rate and high water content, so as to prevent the decline of conductivity and reduce water content. rate, the effect of improving the compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

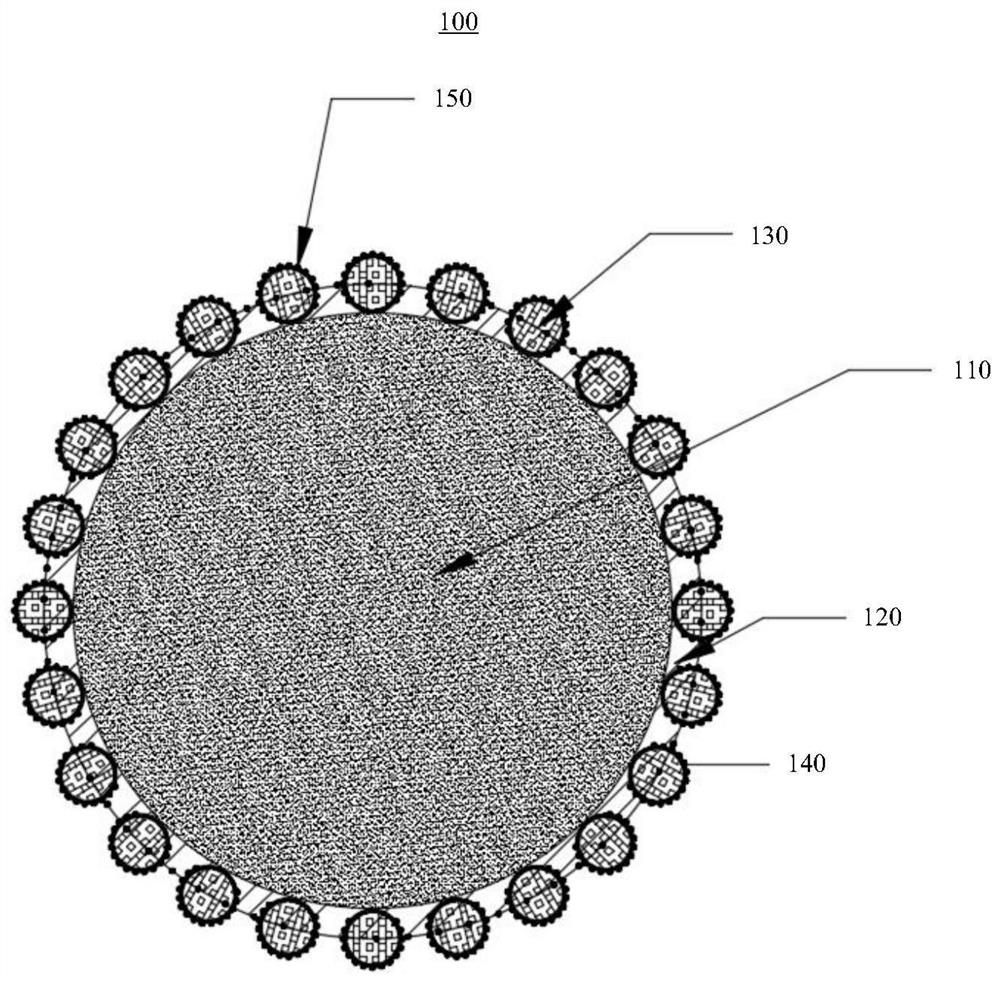

[0037] One aspect of the present invention provides a method for preparing a film-coated proppant, the method comprising:

[0038] A certain amount of aggregate is weighed, and the aggregate is heated to a first preset temperature, and then the heating is stopped.

[0039] Exemplarily, it is possible to choose to weigh a certain amount of quartz sand or ceramsite as aggregate, and stop heating after heating the aggregate to a first preset temperature. In order to make the subsequent feeding and stirring process more smooth, after the aggregate is heated to the first preset temperature, it can be optionally put into the sand mixer to complete the subsequent steps.

[0040] When the temperature of the aggregate drops to the second preset temperature, add a certain amount of the first resin, and control the feeding time to the first preset time, then add a certain amount of silicon micropowder and stir.

[0041] The first resin in this step can improve the strength of the film-c...

Embodiment 1

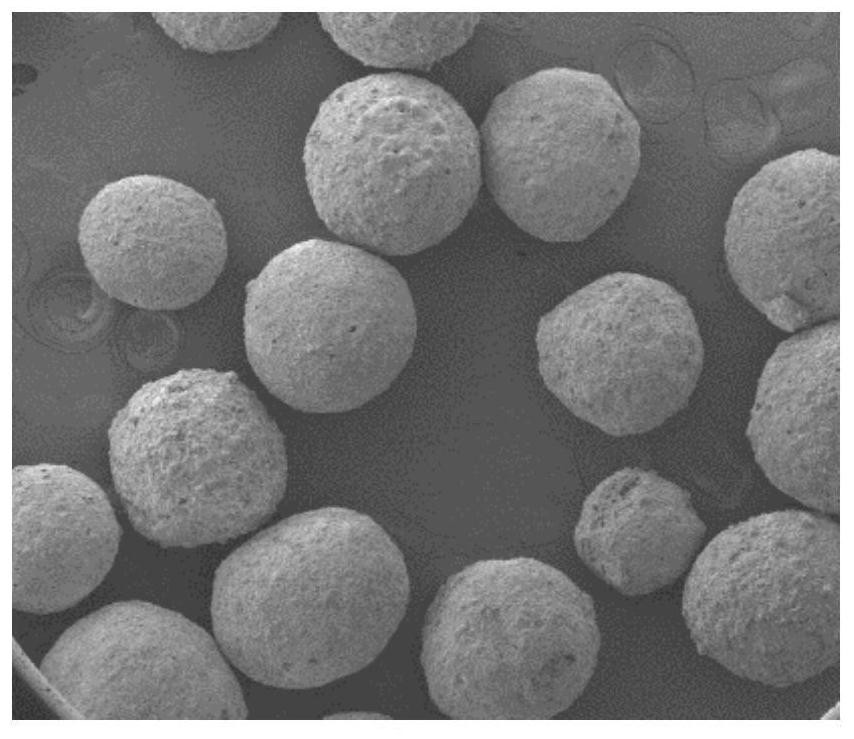

[0071] Weigh 2000 grams of quartz sand, heat the quartz sand to 200°C and stop heating, put the heated quartz sand into the sand mixer, and when the temperature of the quartz sand drops to 180°C, add 10 grams of epoxy 0.07mol / 100g bisphenol A epoxy resin, the feeding time is controlled at 15 seconds, then add 50 grams of silicon micropowder with a particle diameter of 45 μm, stir for 20 seconds, then add 1.0 gram of modified amine curing agent, the feeding Time is controlled at 10 seconds, then add 10 grams of bisphenol A epoxy resins with an epoxy value of 0.07mol / 100g, this addition time is controlled at 15 seconds, then add 100 grams of polytetrafluoroethylene emulsion with a solid content of 40% , the feeding time is controlled at 20 seconds, after the feeding is completed, stir for 10 seconds, then add 1.0 g of modified amine curing agent, the feeding time is controlled at 15 seconds, then cool and sieve to obtain the film-coated proppant.

[0072] After testing, the cont...

Embodiment 2

[0074] The difference from Example 1 is that the bisphenol A epoxy resin added twice in this embodiment is 20 grams, the modified amine curing agent added twice is 5 grams, and the silicon micropowder added is 100 grams. The polytetrafluoroethylene emulsion that adds is 200 grams.

[0075] After testing, the contact angle of the film-coated proppant prepared by this method is 168°, the breakage rate is 2.7%, the roundness and sphericity can be increased to 0.9, and the acid solubility can be reduced to 2.75%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy value | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com