High-temperature secondary annealing method for silicon carbide crystal

A secondary annealing and silicon carbide technology, applied in chemical instruments and methods, crystal growth, single crystal growth, etc., can solve problems such as defects and residual stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The preparation method of silicon carbide briquette is: take a long 4-inch silicon carbide crystal, first use the rounding equipment to round the edges and corners of the edge, and then use the wire cutting machine to remove the head and tail to form a cylindrical crystal block, and then Use paraffin to bond a quartz cylinder on one side of the crystal block as a handle, which is convenient for flattening and compacting operations.

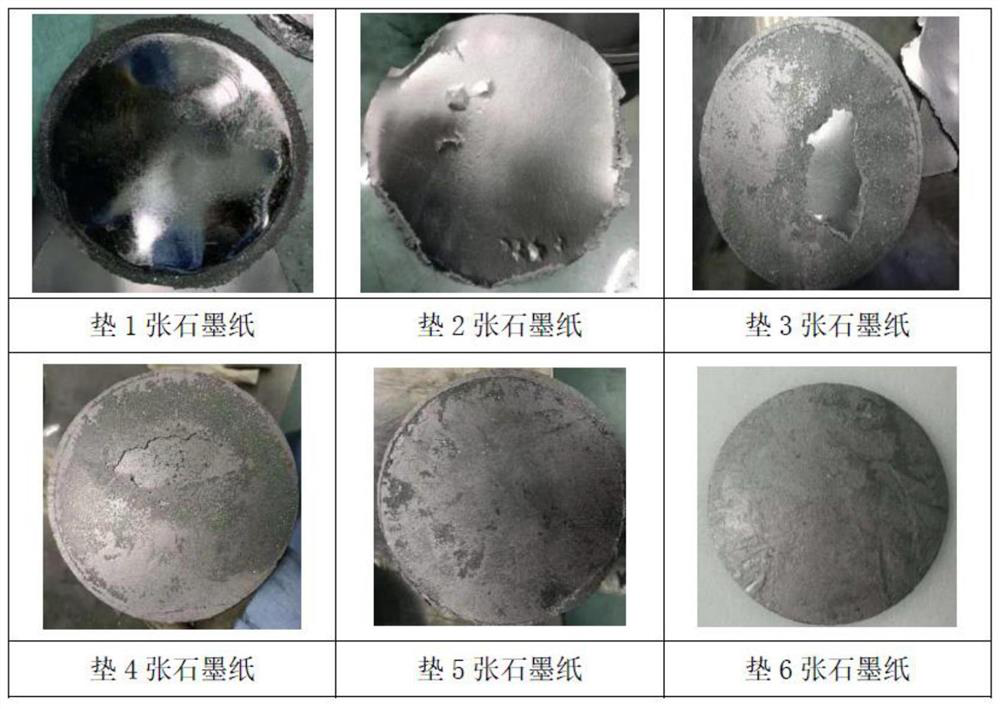

[0036] (2) Put 5-8 pieces of scrubbed graphite paper 2 on the flattened and compacted polycrystalline material 1, which is the same size as the inner diameter of the crucible, and then put a crystal ingot 4 to be annealed on the graphite paper 2 .

[0037] Circular graphite paper 2: Use a grinding tool to cut a rolled graphite paper into a circle with the same inner diameter as the crucible, and then use a heavy object to flatten it.

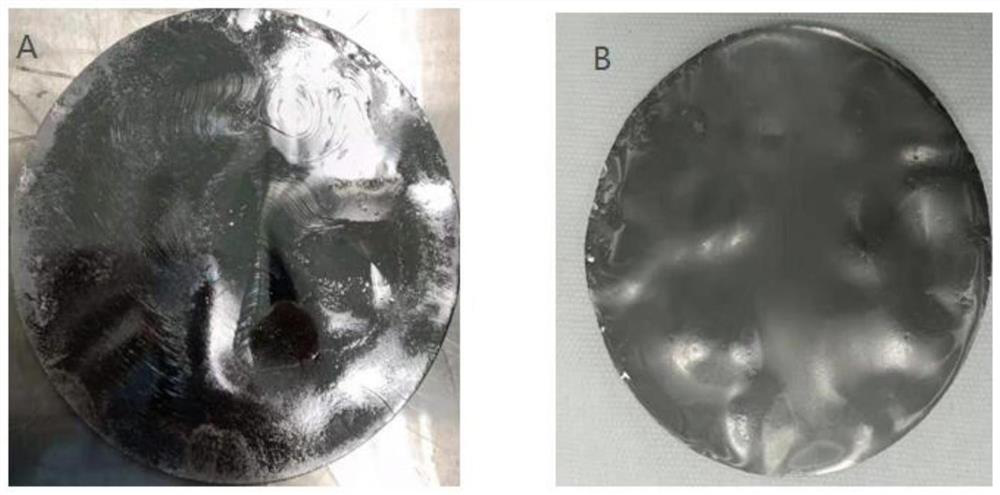

[0038] (3) Make a self-made concentric graphite paper ring 3 with the same outer diameter as the crucible...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com