Silicon dioxide-carbon composite material as well as preparation method and application thereof

A technology of carbon composite materials and silicon dioxide, applied in the direction of secondary batteries, electrochemical generators, active material electrodes, etc., can solve the problems of difficult to effectively control the specific capacity of the negative electrode of the battery, complicated process, and inability to effectively control the relative content, etc. , to achieve good cycle stability, high cycle stability, simple and easy preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

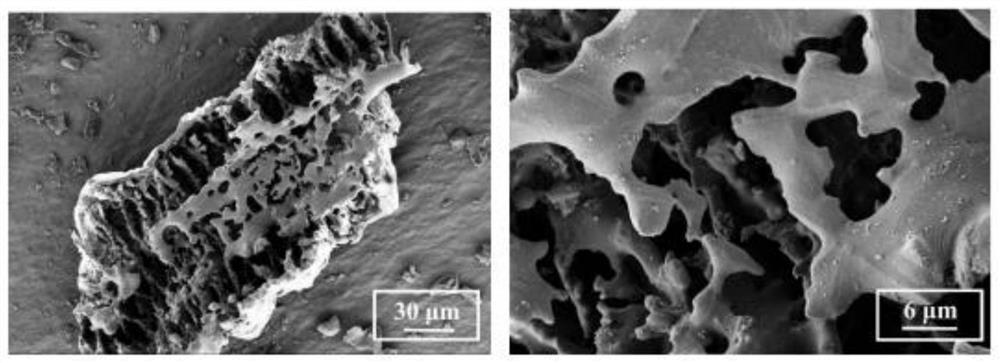

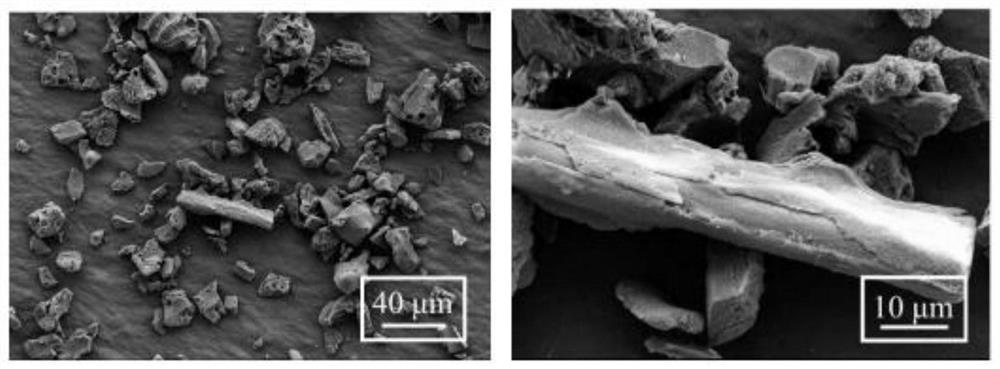

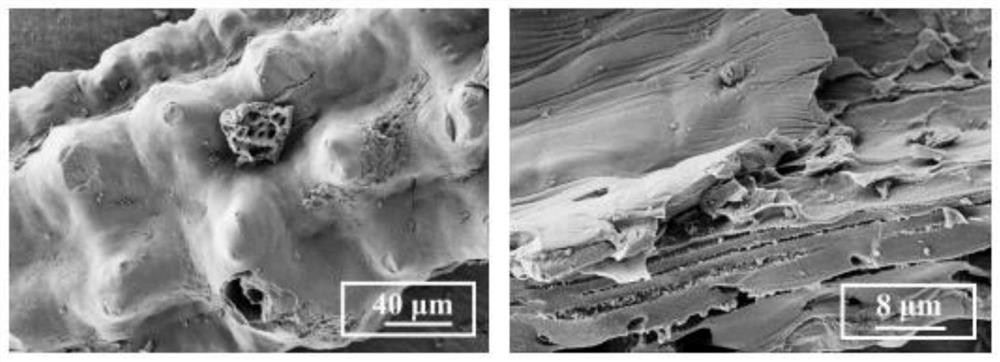

Image

Examples

Embodiment 1

[0043] (1) Add citric acid with a purity of 99.55% into deionized water according to a mass concentration of 3 wt%, stir evenly, and heat to 30°C for use;

[0044] (2) Add the rice husk (the rice husk has been pre-screened to remove large particles of impurities) into the container according to the solid-liquid mass ratio (1:10), stir evenly, soak for 20 minutes, and set aside;

[0045] (3) Stir the soaked rice husks with a spiral stirring and cleaning device (for example, a spiral mixer) at a controlled stirring speed of 200r / min for 30 minutes, then drain the water and set aside. (i.e. pickling pretreatment)

[0046] (4) Add the cleaned rice husks to deionized water at 30°C according to the solid-to-liquid mass ratio (1:10), soak for 30 minutes, stir for 30 minutes at a speed of 300r / min, remove residual impurities from raw materials, and filter to dry Moisturize before use.

[0047] (5) Dry and pulverize the rice husk.

[0048] (6) Load the rice husk into the rice husk a...

Embodiment 2

[0053] (1) Add citric acid with a purity of 99.55% into deionized water according to the mass concentration of 4wt%, stir evenly, and heat to 40°C for use;

[0054] (2) Add rice husks into the container according to the solid-to-liquid mass ratio (1:10), stir evenly, soak for 30 minutes, and set aside;

[0055] (3) Use a spiral mixer with the soaked rice husk at a speed of 250r / min for 40 minutes, drain the water and set aside.

[0056] (4) Add the cleaned rice husks to deionized water at 30°C according to the solid-to-liquid mass ratio (1:10), soak for 30 minutes, stir for 30 minutes at a speed of 300r / min, remove residual impurities from raw materials, and filter to dry Moisturize before use.

[0057] (5) Dry and pulverize the rice husk.

[0058] (6) Load the rice husk into the rice husk according to the volume of the furnace body (1:3).

[0059] (7) Calcination; the calcination conditions are: calcination temperature 900°C, heat preservation for 3 hours; the heating rate...

Embodiment 3

[0062] (1) Add citric acid with a purity of 99.55% into deionized water according to a mass concentration of 5 wt%, stir evenly, and heat to 40°C for use;

[0063] (2) Add rice husks into the container according to the solid-to-liquid mass ratio (1:10), stir evenly, soak for 45 minutes, and set aside;

[0064] (3) Use a spiral mixer with the soaked rice husk at a speed of 300r / min for 50 minutes, drain the water and set aside.

[0065] (4) Add the cleaned rice husks to deionized water at 30°C according to the solid-to-liquid mass ratio (1:10), soak for 30 minutes, stir for 30 minutes at a speed of 300r / min, remove residual impurities from raw materials, and filter to dry Moisturize before use.

[0066] (5) Dry and pulverize the rice husk.

[0067] (6) Load the rice husk into the rice husk according to the volume of the furnace body (1:3).

[0068] (7) The calcination conditions are as follows: a calcination temperature of 900° C. and a heat preservation time of 3 hours; the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com