Device and method for remediating organically polluted soil with resistance heating coupling oxidant

A resistance heating and organic pollution technology, which is applied in the restoration of polluted soil and the removal of solid waste, can solve the problems of changing soil physical and chemical properties, long heating time, and chemical reagent residue, so as to reduce system energy consumption and shorten repair time Cycle, the effect of preventing the occurrence of dry well

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The invention provides a high-efficiency and energy-saving device for remediating organic polluted soil with resistance heating coupled with electric transport of oxidant. In order to clarify the implementation purpose, implementation technical scheme and implementation advantages of the present invention, the present invention will be described in further detail below in conjunction with the accompanying drawings and implementation methods. Under the circumstances, several modifications and improvements can also be made, which are also deemed to belong to the protection scope of the present invention.

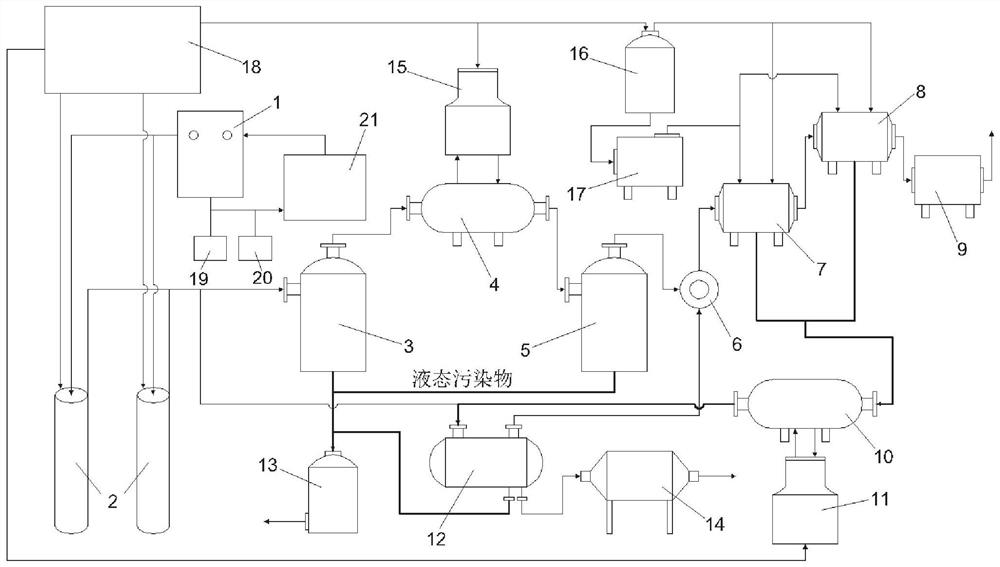

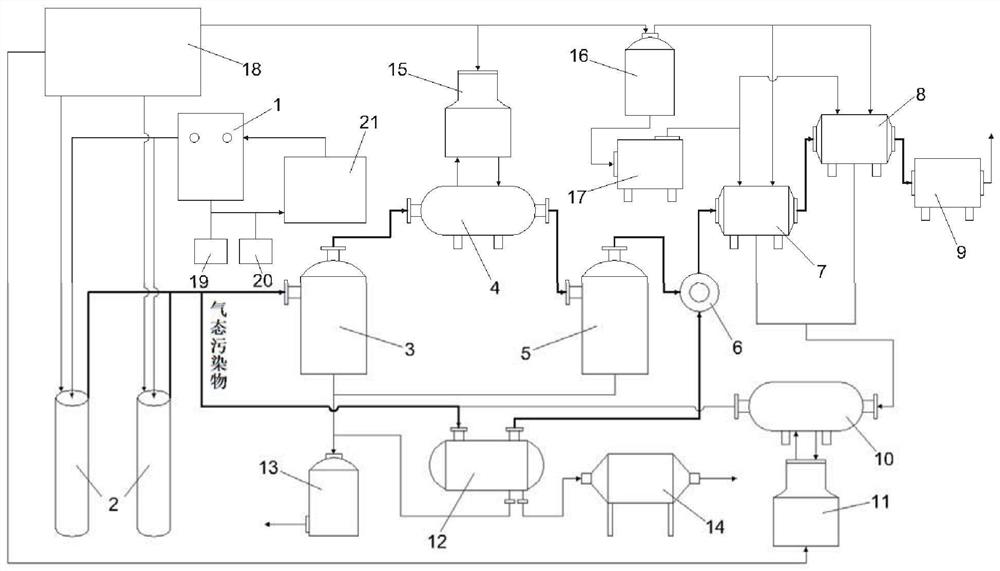

[0034] like figure 1 and figure 2 As shown, the present invention provides a device for remediating organic polluted soil with resistance heating coupling oxidant, and the device for remediating organic polluted soil includes a power system 1, an electrode well 2, a primary gas-water separator 3, a first condenser 4, and a secondary Primary gas-water separator 5, fan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com