High-strength quick-drying ceramic tile adhesive and preparation method thereof

A quick-drying, tile adhesive technology, applied in the field of building materials, can solve the problems of inability to meet rapid construction, poor quick-drying performance of tile adhesive, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

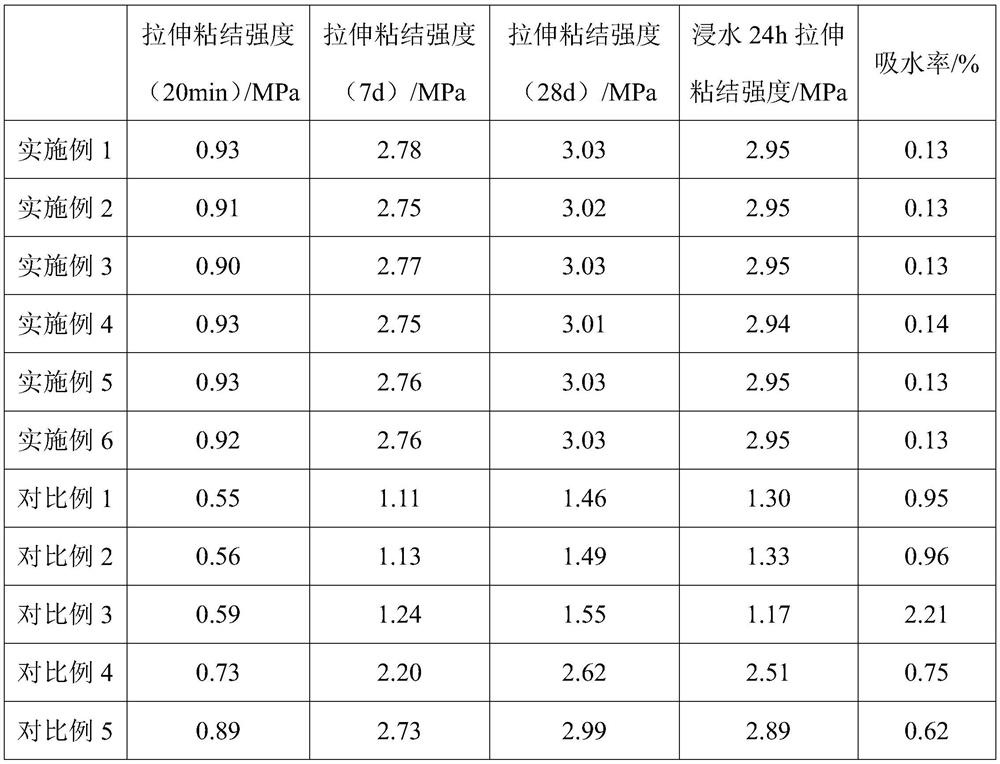

Examples

Embodiment 1

[0027] A high-strength quick-drying tile adhesive, which consists of the following ingredients in parts by weight:

[0028] 90 parts of cement, 50 parts of river sand, 30 parts of fly ash, 1 part of rice bran oil, 1 part of water retaining agent, 0.1 part of early strength agent, 2 parts of polyvinyl alcohol, 20 parts of epoxidized styrene-butadiene rubber powder, styrene-butadiene emulsion 100 copies.

[0029] Among them, the water-retaining agent is a mixture of cellulose / bentonite-based superabsorbent resin and hydroxypropyl methylcellulose ether at a mass ratio of 10:1.

[0030] The preparation method of cellulose / bentonite-based superabsorbent resin is as follows:

[0031] Under ice bath, add sodium hydroxide aqueous solution with a mass concentration of 10% to acrylic acid to make the neutralization degree of acrylic acid 80%. After stirring and reacting for 20 minutes, add acrylamide (70% of the mass of acrylic acid) and bentonite, and stir After reacting for 10 minut...

Embodiment 2

[0038] A high-strength quick-drying tile adhesive, which consists of the following ingredients in parts by weight:

[0039] 90 parts of cement, 50 parts of river sand, 30 parts of fly ash, 1 part of rice bran oil, 1 part of water retaining agent, 0.1 part of early strength agent, 1 part of polyvinyl alcohol, 20 parts of epoxidized styrene-butadiene rubber powder, styrene-butadiene emulsion 100 copies.

[0040] Among them, the water-retaining agent is a mixture of cellulose / bentonite-based superabsorbent resin and hydroxypropyl methylcellulose ether at a mass ratio of 10:1.

[0041] The preparation method of cellulose / bentonite-based superabsorbent resin is as follows:

[0042] Under ice bath, add sodium hydroxide aqueous solution with a mass concentration of 10% to acrylic acid to make the neutralization degree of acrylic acid 80%. After stirring and reacting for 30 minutes, add acrylamide (70% of the mass of acrylic acid) and bentonite, and stir After reacting for 5 minutes...

Embodiment 3

[0048] A high-strength quick-drying tile adhesive, which consists of the following ingredients in parts by weight:

[0049] 80 parts of cement, 60 parts of river sand, 30 parts of fly ash, 2 parts of rice bran oil, 0.1 part of water retaining agent, 1 part of early strength agent, 1 part of polyvinyl alcohol, 25 parts of epoxidized styrene-butadiene rubber powder, styrene-butadiene emulsion 100 copies.

[0050] Among them, the water-retaining agent is a mixture of cellulose / bentonite-based superabsorbent resin and hydroxypropyl methylcellulose ether at a mass ratio of 15:1.

[0051] The preparation method of cellulose / bentonite-based superabsorbent resin is as follows:

[0052] Under ice bath, add sodium hydroxide aqueous solution with a mass concentration of 5% to acrylic acid, so that the neutralization degree of acrylic acid is 80%, and after stirring for 10 minutes, add acrylamide (70% of the mass of acrylic acid) and bentonite, and stir After reacting for 10 minutes, ad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com