A kind of cast-type energetic binder-based mixed explosive and preparation method thereof

A technology of mixing explosives and adhesives, applied in the directions of explosives, non-explosive/non-thermal agents, non-explosive fillers/gelling agents/thickeners, etc. Too high, large differences in mass content, etc., to shorten the curing reaction cycle, improve chemical reactivity, and high density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

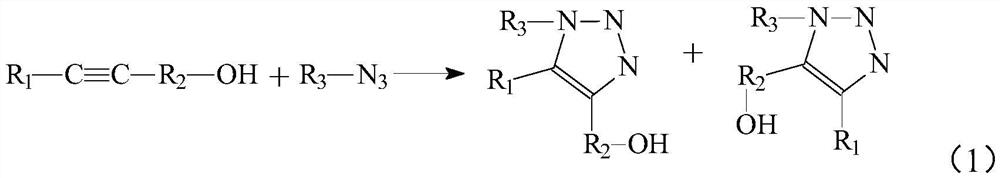

Method used

Image

Examples

preparation example Construction

[0094] The invention also discloses a preparation method of a castable energy-containing binder-based mixed explosive, comprising the following steps:

[0095] 1) Weigh the azide adhesive, alkynyl alcohol compound, functional auxiliaries and energy-containing plasticizer into the container according to the proportioning requirements, and after stirring evenly, add it to the kneader;

[0096] 2) Add rare earth-metal alloy fuel, oxidant, explosive and isocyanate curing agent into the premix described in step 1 in turn according to the proportioning requirements, and fully mix them uniformly in the kneader to form a compound with good fluidity and leveling. syrup;

[0097] 3) The slurry obtained in step 2) is poured into the warhead or the mold under vacuum conditions, and cured for 4 to 6 days at a temperature of 40°C to 60°C to obtain a pourable energetic binder-based mixed explosive.

[0098] Among them, the composition and proportion (mass percentage) of the cast-type energe...

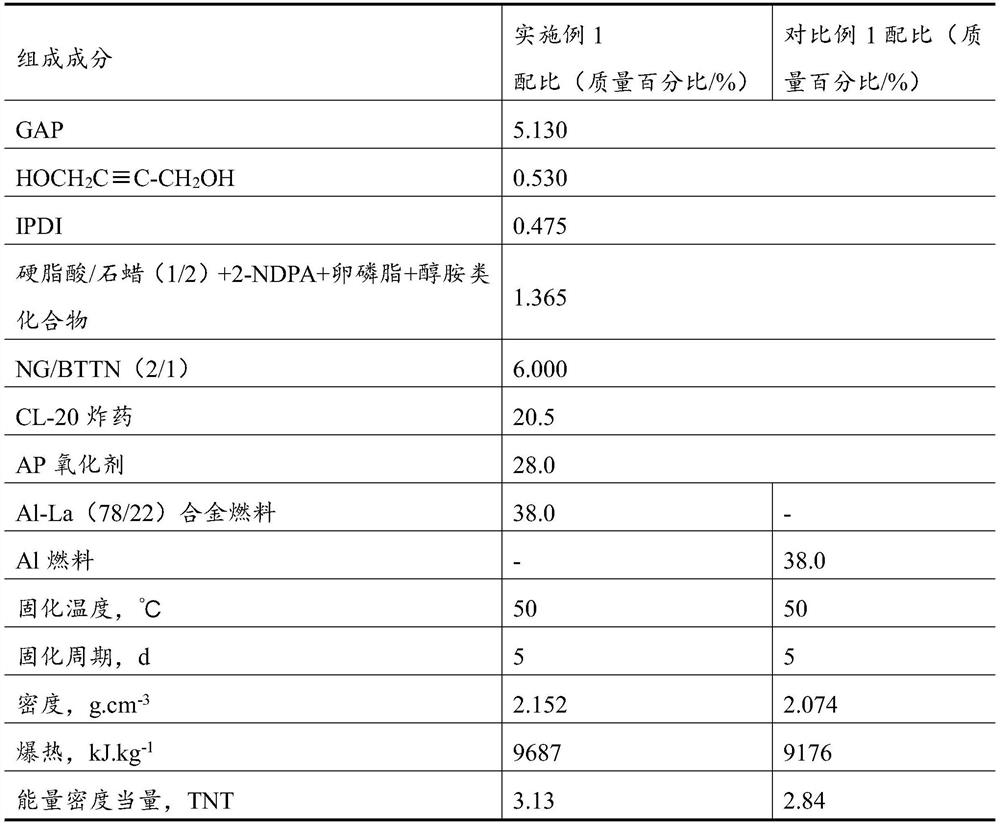

Embodiment 1 and comparative example 1

[0117] Table 1 Composition, ratio and performance test results of Example 1 and Comparative Example 1

[0118]

[0119] Table 1 shows that the density of Comparative Example 1 is 2.074 g / cm 3 , the explosion heat is 9176kJ / kg, the energy density equivalent is 2.84TNT; the density of Example 1 is 2.152g / cm 3 , the explosion heat is 9687kJ / kg, and the energy density equivalent is 3.12TNT, which is significantly higher than that of Comparative Example 1.

[0120] The results show that the rare earth-metal alloy fuel selected by the present invention is beneficial to improve the density, detonation heat and energy density of the mixed explosive compared with the common metal fuel.

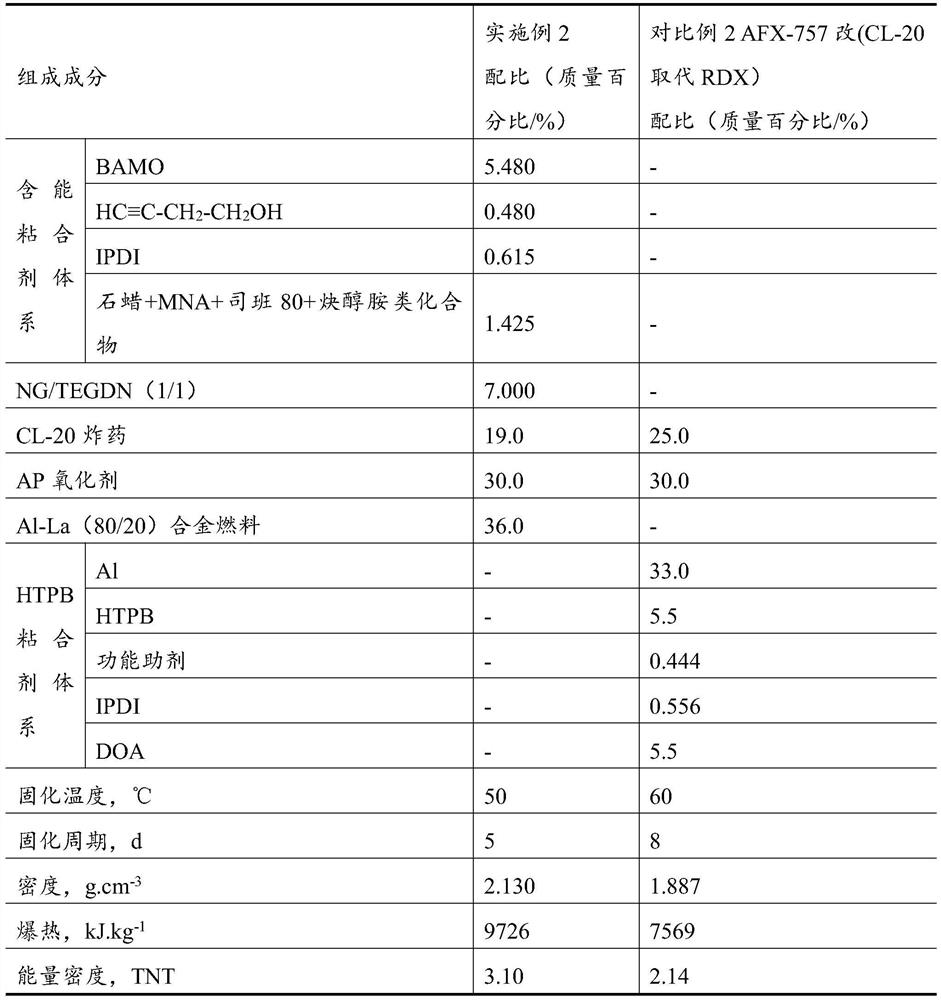

Embodiment 2 and comparative example 2

[0122] Table 2 Composition, ratio and performance test results of Example 2 and Comparative Example 2

[0123]

[0124] Table 2 shows that the density of Example 2 with a solids content of 85% is 2.130 g / cm 3 , the explosion heat is 9726kJ / kg, the energy density is 3.10TNT, the explosive can complete the curing reaction in 5d when the curing temperature is 50 ℃; the solid content is 88% in Comparative Example 2 (AFX-757 modified formula (CL-20 etc The density and heat of explosion of RDX)) are 1.887g / cm, respectively 3 , 7569kJ / kg, and the energy density is 2.14TNT, which are all lower than those of Example 2, and the curing reaction of Comparative Example 2 takes 8d to complete the curing reaction at 60°C.

[0125] The results show that 1) the energetic binder has good compatibility with the energetic plasticizer, and the density, explosion heat and energy density of the prepared mixed explosive are greatly improved; 2) the energetic binder is bonded by azide The additio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com