Desulfurized gypsum regenerated plastic composite material as well as preparation method and application thereof

A technology of recycled plastics and composite materials, applied in the field of composite materials, can solve the problems of waste plastics not easy to age and degrade, ecological environment damage, etc., and achieve the effect of no wood knots and low water absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~6

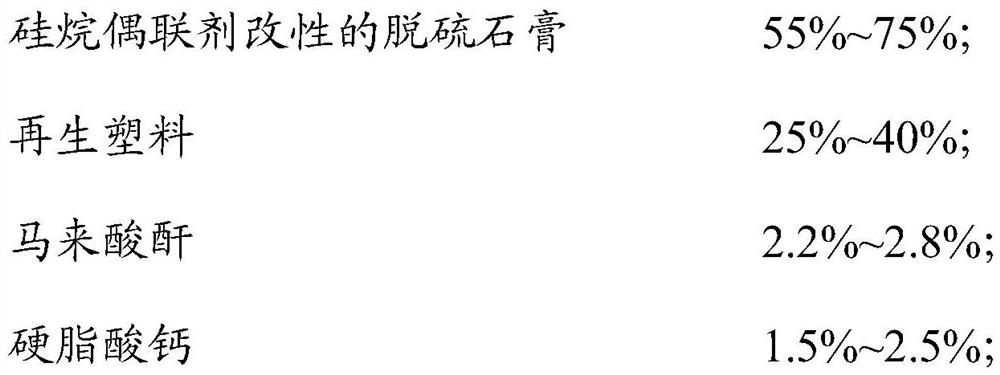

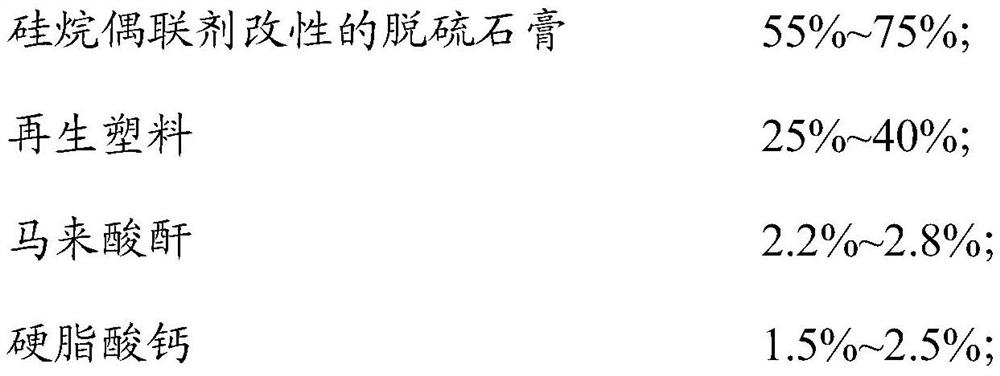

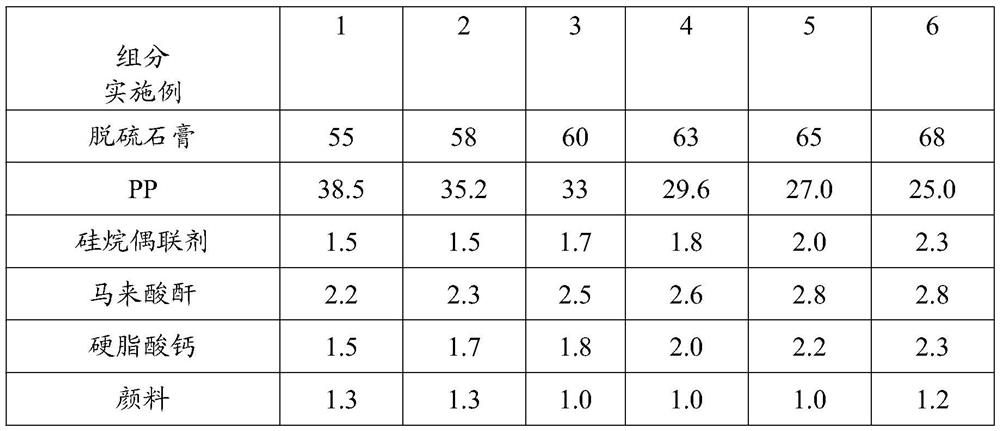

[0025] (1) Prepare raw materials by the raw material formula shown in Table 1:

[0026] Table 1 raw material formula (by each component accounts for the percentage of raw material gross weight)

[0027]

[0028] (2) Add desulfurized gypsum and silane coupling agent into the mixer, and release after stirring for 5 minutes to obtain desulfurized gypsum modified by silane coupling agent.

[0029] (3) Put the desulfurized gypsum modified by the silane coupling agent prepared in step (2) into the high-speed mixer together with the rest of the raw materials, set the speed at 1000 rpm, turn on the high-speed mixer, stir for 10 minutes, and discharge the materials for use .

[0030] (4) Granulation: Put the mixed raw materials into the granulator. The temperature of the granulator is set at 220°C, 200°C, 190°C, 180°C, 175°C, 175°C, 170°C, and 170°C. After high-temperature plasticization, it is extruded from a granulation die and cut into composite material granules with a diamete...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com