Nickel sponge/Ni9S8 composite material as well as preparation method and application thereof

A composite material, sponge nickel technology, applied in the field of sponge nickel/octasulfide nine nickel composite materials and its preparation, can solve the problems of high price, poor cycle stability, low natural abundance and other problems of noble metal catalysts, and achieve effective active reaction area, improved electrochemical performance, and the effect of large active reaction area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

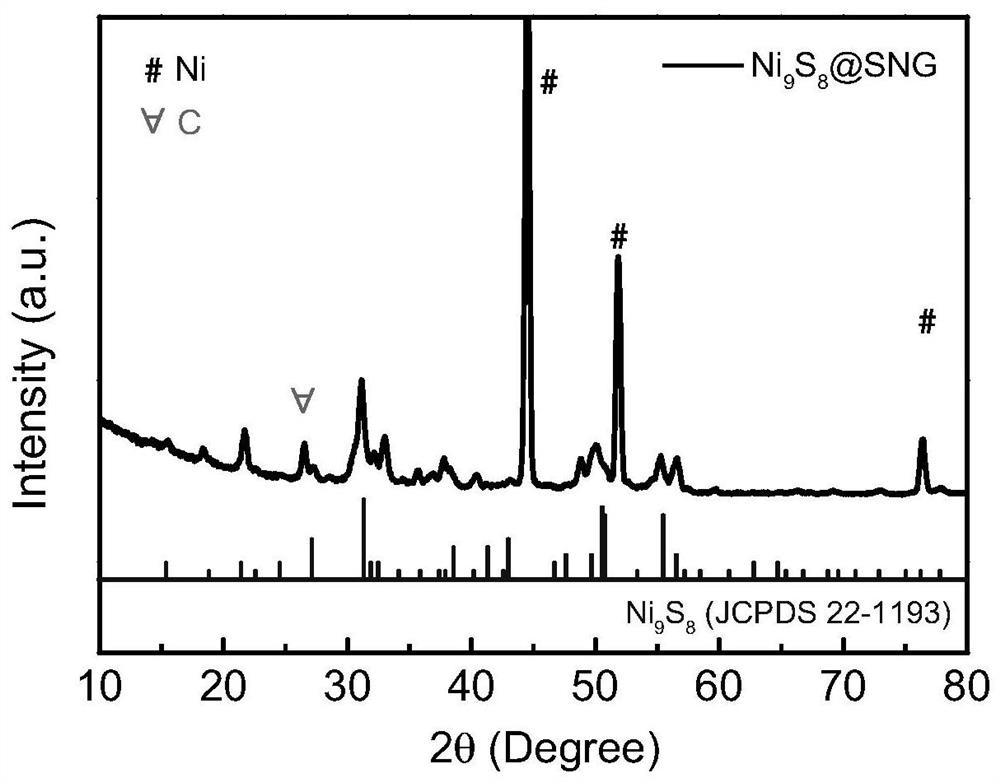

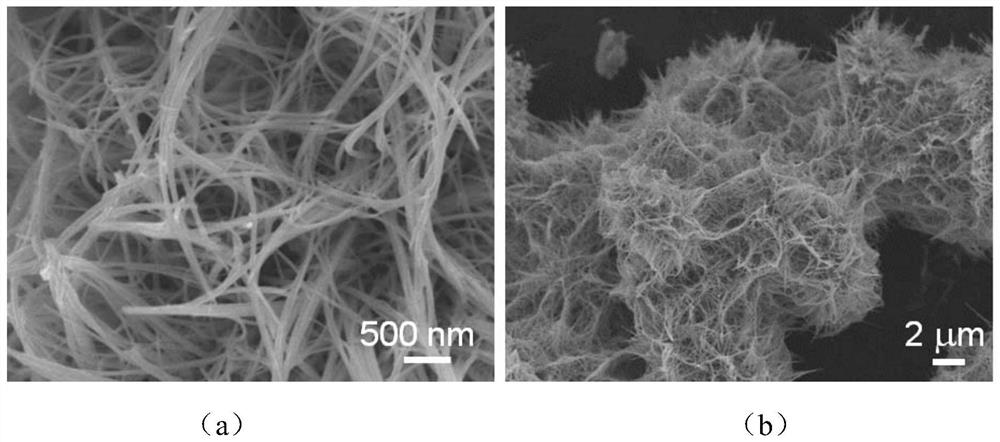

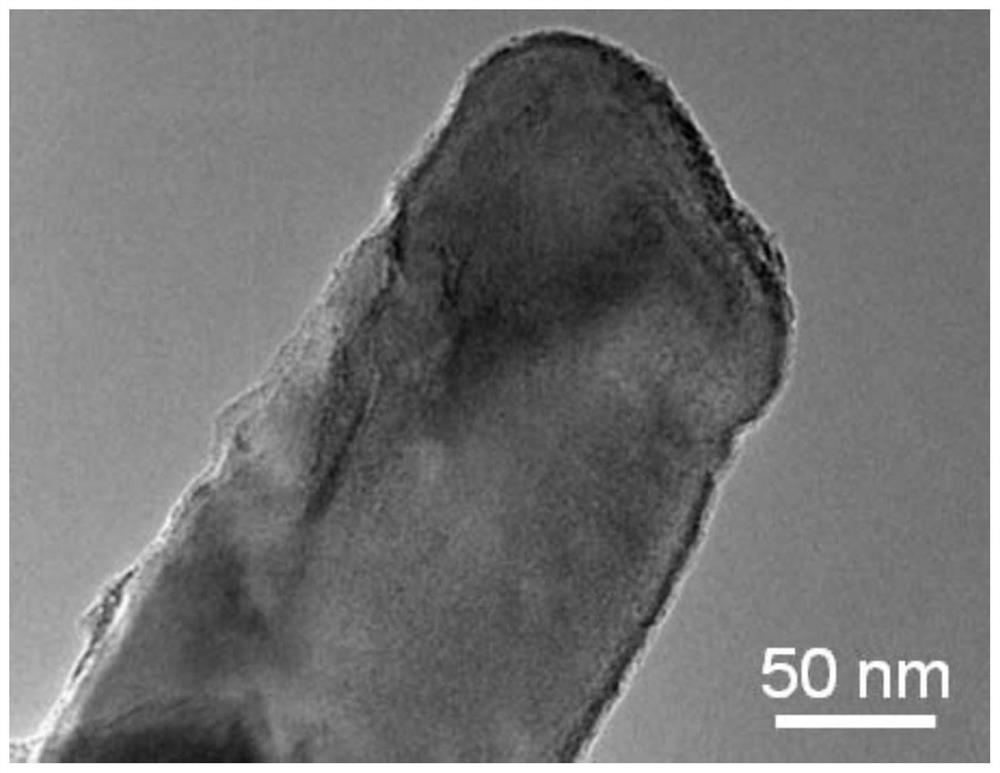

[0033] Dissolve 1.243g of nickel acetate in 69mL of deionized water, stir until the solution becomes clear, then slowly add 6mL of hydrazine hydrate, and continue stirring until the solution becomes clear. Transfer the above solution to the lining of the hydrothermal reaction kettle, install the stainless steel shell, tighten it and place it in an oven at 150°C for 7 hours. After the reaction is over, after the reactor is cooled to room temperature, the nickel sponge grown in the lining is taken out. The dried nickel sponge sample is placed in a quartz boat, and then placed in the middle of the CVD tube furnace, while the bubbler is filled with an appropriate ethanol solution as a carbon source for the reaction. After the argon gas was introduced into the tube furnace to evacuate it, the mixture of argon gas (160 sccm) and hydrogen gas (20 sccm) was continuously fed in, and the temperature of the furnace was raised to 850°C within 40 minutes. Ethanol carbon source, the reacti...

Embodiment 2

[0036]Dissolve 1.343g of nickel acetate in 69mL of deionized water, stir until the solution becomes clear, then slowly add 7mL of hydrazine hydrate, and continue stirring until the solution becomes clear. Transfer the above solution to the inner lining of the hydrothermal reaction kettle, install the stainless steel shell, tighten it and place it in an oven at 180°C for 9 hours. After the reaction is over, after the reactor is cooled to room temperature of 25°C, the nickel sponge grown in the lining is taken out. The dried nickel sponge sample is placed in a quartz boat, and then placed in the middle of the CVD tube furnace, while the bubbler is filled with an appropriate ethanol solution as a carbon source for the reaction. After the argon gas was introduced into the tube furnace to evacuate it, the mixture of argon gas (165 sccm) and hydrogen gas (15 sccm) was continuously fed in, and the temperature of the furnace was raised to 950°C within 40 minutes. Ethanol carbon sourc...

Embodiment 3

[0039] Dissolve 1.343g of nickel acetate in 69mL of deionized water, stir until the solution becomes clear, then slowly add 7mL of hydrazine hydrate, and continue stirring until the solution becomes clear. Transfer the above solution to the lining of the hydrothermal reaction kettle, install the stainless steel shell, tighten it and place it in an oven at 185°C for 6 hours. After the reaction is over, after the reactor is cooled to room temperature of 25°C, the nickel sponge grown in the lining is taken out. The dried nickel sponge sample is placed in a quartz boat, and then placed in the middle of the CVD tube furnace, while the bubbler is filled with an appropriate ethanol solution as a carbon source for the reaction. After the argon gas was introduced into the tube furnace to evacuate, the mixture of argon gas (155 sccm) and hydrogen gas (25 sccm) was continuously fed in, and the temperature of the furnace was raised to 950°C within 40 minutes. Ethanol carbon source, the r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com