Natural plant pigment cigarette paper with low cracking rate and high gray value after combustion

A natural plant and cigarette paper technology, applied in the direction of adding plant raw materials, paper, pigments/opacifiers, etc., can solve problems that affect the coloring effect of cigarette paper, affect the user's sensory experience, and the large color difference of cigarette paper, etc., to achieve richness Effects of cigarette smoke characteristics, reduction of crack rate after combustion, and color stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

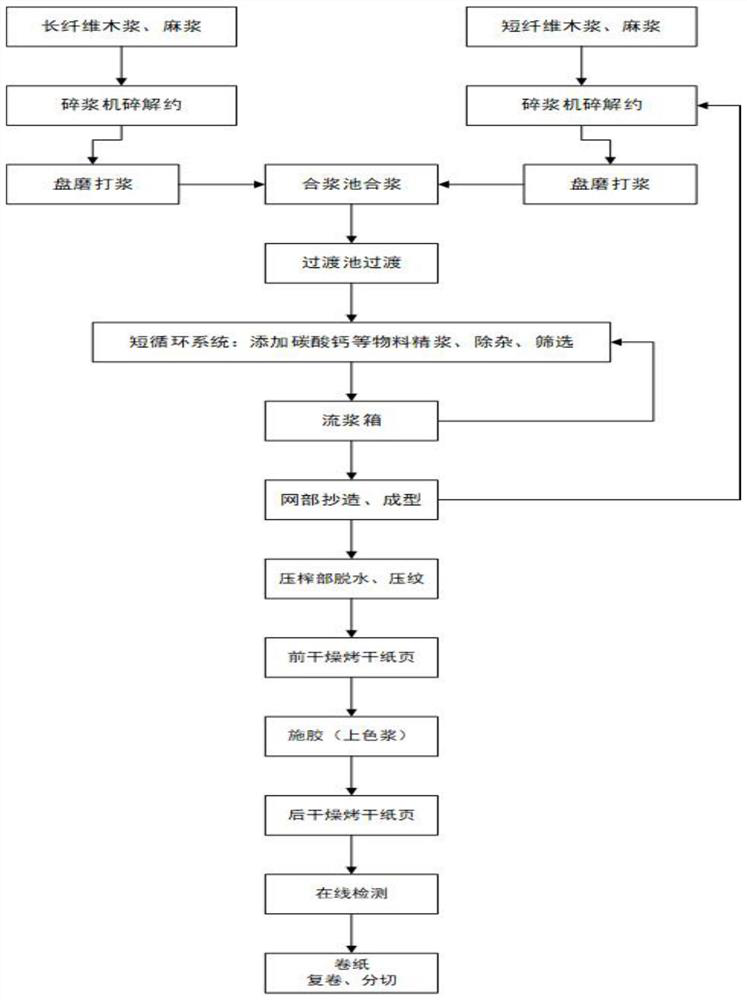

Method used

Image

Examples

Embodiment 1

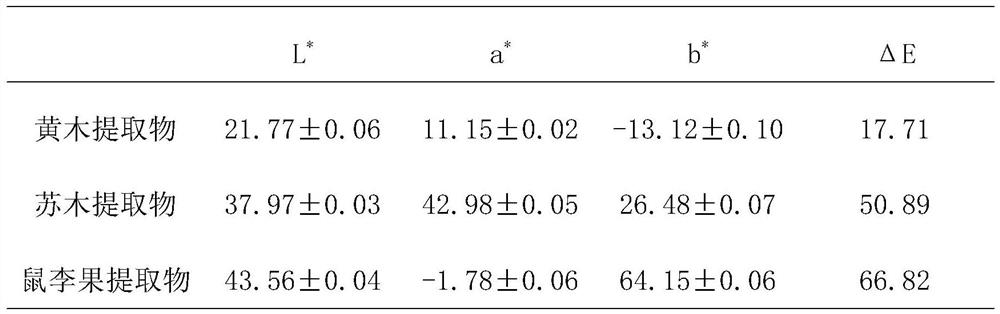

[0037] A method for preparing natural plant pigmented cigarette paper with low crack rate and high gray value after burning, in which coloring material is added in the color paste stage in the cigarette paper preparation process, and the coloring material is composed of natural plant coloring material and mixed with water, the natural plant color is one or more of yellow wood extract, cascara fruit extract, and sumac extract, and the natural plant color is adjusted according to the color set by the cigarette paper The ratio of yellow wood extract, buckthorn fruit extract and sumac extract in the material.

[0038] Yellow wood extract, cascara fruit extract, sumac extract, etc. are called monomer colorants in this paper.

[0039] The method for adjusting the ratio adopts the response surface method. When the color of the cigarette paper is set to be dark red, the specific operation of the response surface method is as follows:

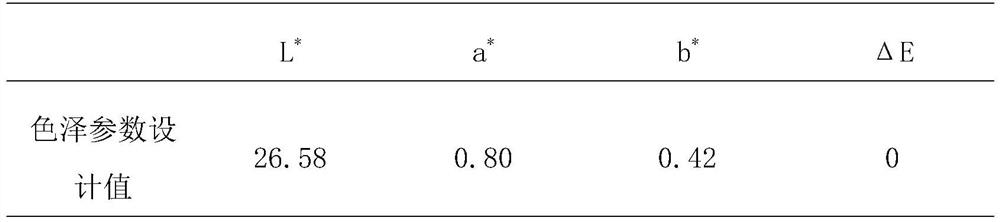

[0040] Step (1), confirm the color parameters (L...

Embodiment 2

[0100] Using the method of Example 1, using the three natural monomeric pigments of the present invention, yellow wood extract, sumac extract, and cascara fruit extract, to prepare colored cigarette paper samples, only the specific formula ratio needs to be changed.

[0101] For example: the first in the present embodiment 2:

[0102] The formula adopted is yellow wood extract: sumac extract: cascara fruit extract=0.400:0.400:0.200, and reddish-purple cigarette paper C is obtained.

[0103] For example: the second in this embodiment 2:

[0104] The formula used is yellow wood extract: sumac extract: cascara fruit extract = 0.800:0.200:0.000, and black cigarette paper D is obtained.

[0105] For example: the third in this embodiment 2:

[0106] The adopted formula is yellow wood extract: sumac extract: cascara fruit extract=0.450:0.500:0.050, and dark purple cigarette paper E is obtained.

[0107] The above-mentioned cigarette paper C, cigarette paper D, and cigarette paper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com