Sensing equipment capable of detecting ethanol in high-temperature environment and processing method

A technology for high-temperature environment and sensing equipment, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., and can solve problems such as inability to detect gases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

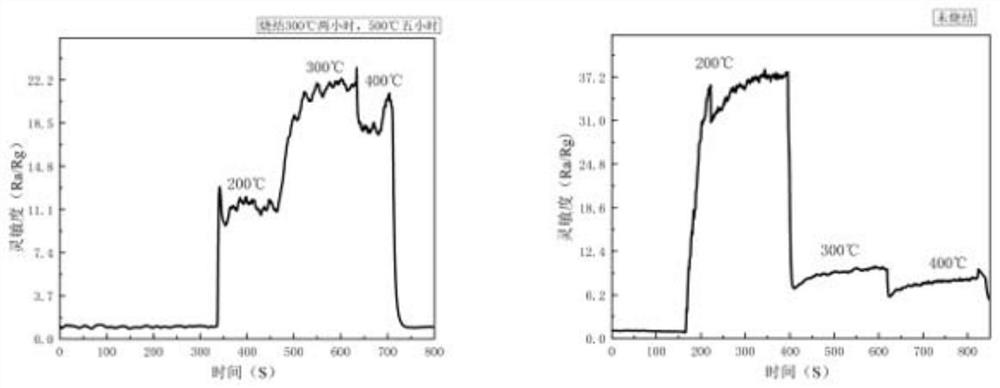

[0033] The present invention is a kind of sensing device that can detect ethanol under high temperature environment, comprises: silicon substrate, electrode layer and thin film sensitive material layer, and electrode layer is a comb electrode, and sensitive material layer is made of SnO 2 Composed of thin films, the detection object of the sensitive material layer is ethanol in a high temperature environment.

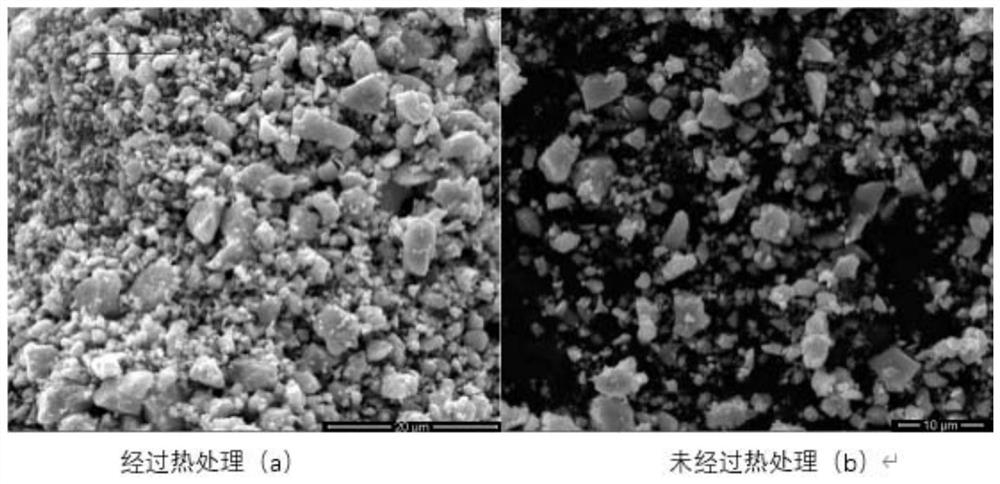

[0034] In this example, the preparation of SnO 2 The film steps are as follows:

[0035] S1. Weigh 0.35g SnCl 4 ·5H 2 O dissolve it in solution A, solution A is prepared by 10ml deionized water and 10ml ethanol;

[0036] S2. Adjust the pH value of solution A by using NaOH solution with pH=13 until the pH of solution A=4 to obtain solution B;

[0037] S3. Add 1ml polyethylene glycol to solution B, stir and sonicate for 30min to obtain solution C;

[0038] S4. Pour solution C into a reaction kettle with a filling rate of 70% to 75%, and put it into a hydrothermal dry...

Embodiment 2

[0045] The only difference from Embodiment 1 is that the detection unit, the conversion unit, the processing unit, the early warning unit and the protective shell, the detection unit, the conversion unit, the processing unit and the early warning unit are all packaged inside the protective shell. When it is necessary to detect the ethanol concentration in the high-temperature environment, first, the detection unit detects the ethanol content in the high-temperature environment in the form of an electrical signal; then, the conversion unit converts the electrical signal into a digital signal; then, the processing unit processes the digital signal and Obtain the ethanol concentration, judge the size of the ethanol concentration and the preset threshold, and send an instruction to start the early warning when the ethanol concentration is greater than or equal to the preset threshold; finally, the early warning unit receives the instruction to start the early warning and performs an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com