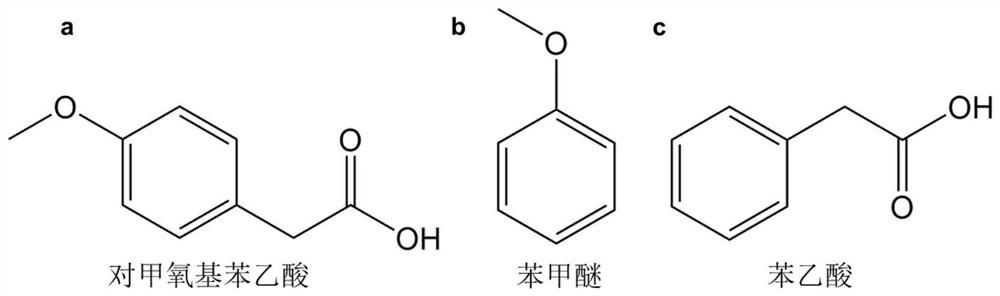

Perovskite solar cell based on p-methoxyphenylacetic acid passivator

A technology of p-methoxybenzene and solar cells, applied in circuits, electrical components, photovoltaic power generation, etc., can solve the problem of limited performance improvement of devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

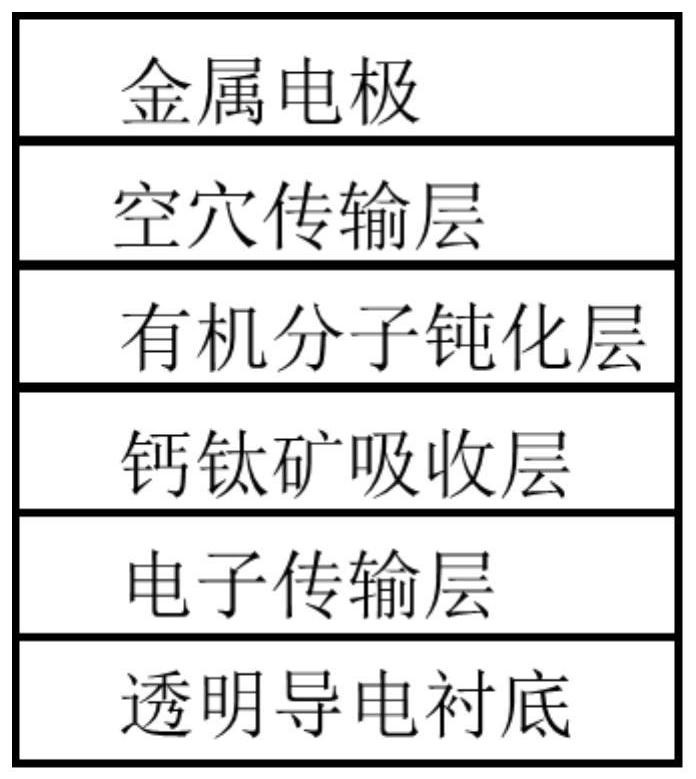

[0020] 1) Use ITO / glass as the substrate, and clean it ultrasonically with cleaning agent, deionized water, acetone, and isopropanol.

[0021] 2) Using SnO with a concentration of 2.5wt.% 2 The electron transport layer was prepared from the solution and spin-coated at 4000rpm for 30s.

[0022] 3) On SnO 2 On the transport layer, a perovskite absorber layer was prepared by a two-step spin-coating method. 1.5M PbI 2 The solution was spin-coated at 1500rpm for 30s and annealed at 70°C. Then in PbI 2 The organic salt solution was added dropwise on the surface of the layer, spin-coated at 2000rpm for 30s and annealed at 150°C to obtain a perovskite film.

[0023]4) Prepare a p-methoxyphenylacetic acid passivation layer on the perovskite absorber layer. The solubility of p-methoxyphenylacetic acid solution is 3mg / ml, the solvent is chlorobenzene, and it is spin-coated at 5000rpm for 30s.

[0024] 5) Prepare a Spiro-OMeTAD hole transport layer on the passivation layer, and spi...

Embodiment 2

[0031] 1) Use ITO / glass as the substrate, and clean it ultrasonically with cleaning agent, deionized water, acetone, and isopropanol.

[0032] 2) Using SnO with a concentration of 2.5wt.% 2 The electron transport layer was prepared from the solution and spin-coated at 4000rpm for 30s.

[0033] 3) On SnO 2 On the transport layer, a perovskite absorber layer was prepared by a two-step spin-coating method. 1.5M PbI 2 The solution was spin-coated at 1500rpm for 30s and annealed at 70°C. Then in PbI 2 The organic salt solution was added dropwise on the surface of the layer, spin-coated at 2000rpm for 30s and annealed at 150°C to obtain a perovskite film.

[0034] 4) Anisole passivation layer was prepared on the perovskite absorber layer. Anisole was diluted in chlorobenzene at a concentration of 3 mg / ml and spin-coated at 5000 rpm for 30 s.

[0035] 5) Prepare a Spiro-OMeTAD hole transport layer on the passivation layer, and spin-coat the Spiro-OMeTAD solution at 4000rpm for...

Embodiment 3

[0038] 1) Use ITO / glass as the substrate, and clean it ultrasonically with cleaning agent, deionized water, acetone, and isopropanol.

[0039] 2) Using SnO with a concentration of 2.5wt.% 2 The electron transport layer was prepared from the solution and spin-coated at 4000rpm for 30s.

[0040] 3) On SnO 2 On the transport layer, a perovskite absorber layer was prepared by a two-step spin-coating method. 1.5M PbI 2 The solution was spin-coated at 1500rpm for 30s and annealed at 70°C. Then in PbI 2 The organic salt solution was added dropwise on the surface of the layer, spin-coated at 2000rpm for 30s and annealed at 150°C to obtain a perovskite film.

[0041] 4) Prepare a phenylacetic acid passivation layer on the perovskite absorber layer. The solubility of the phenylacetic acid solution is 3mg / ml, the solvent is chlorobenzene, and it is spin-coated at 5000rpm for 30s.

[0042] 5) Prepare a Spiro-OMeTAD hole transport layer on the passivation layer, and spin-coat the Sp...

PUM

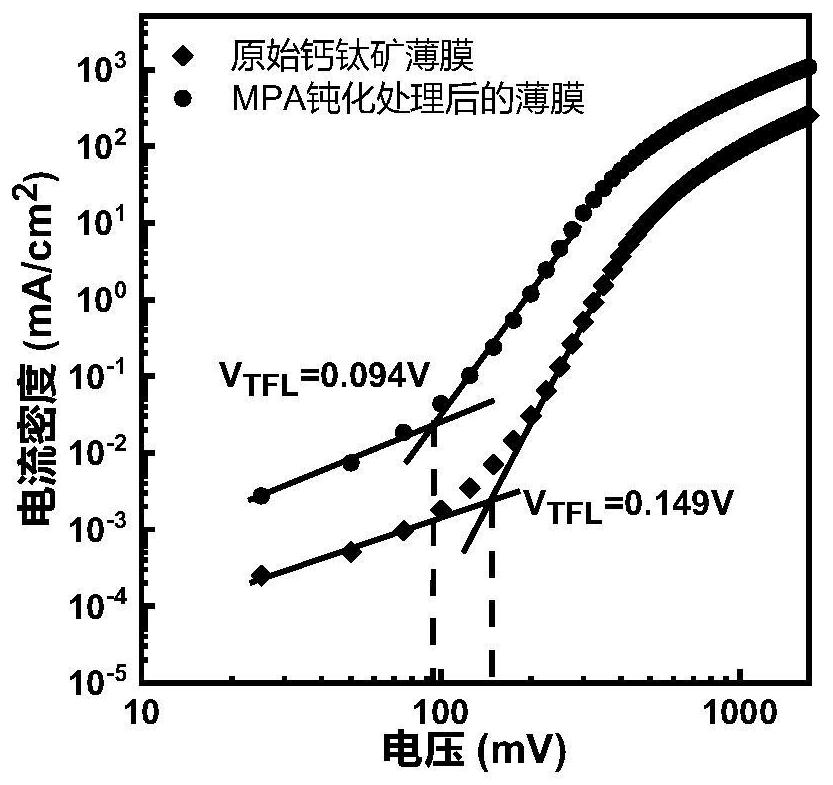

| Property | Measurement | Unit |

|---|---|---|

| Defect density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com