Method for changing distillation conditions of binary mixture system by using electrostatic field

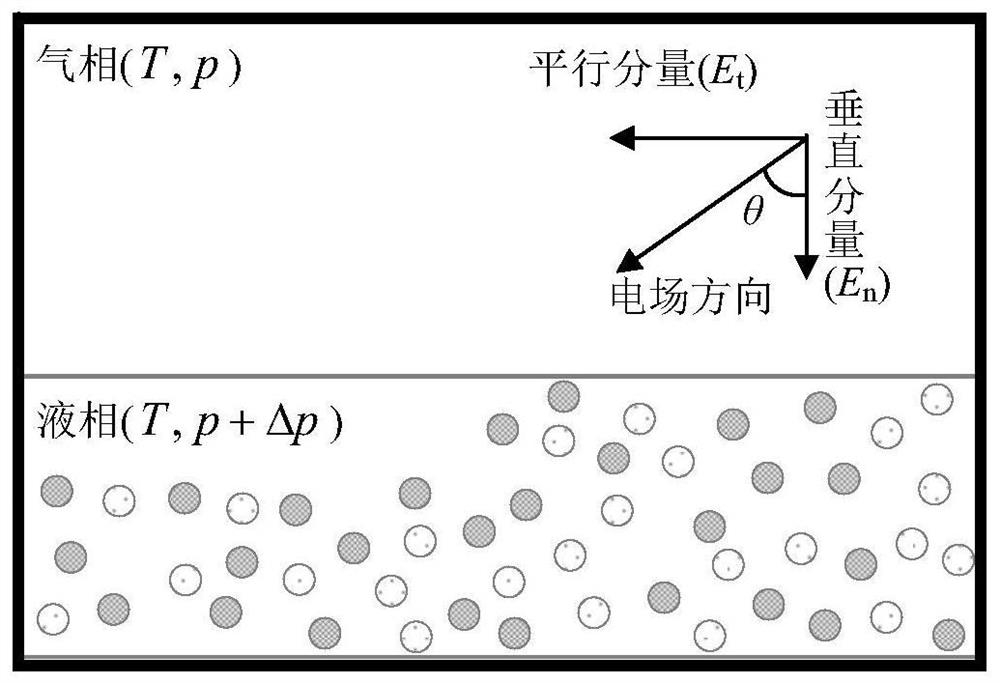

An electrostatic field and mixture technology is applied in the field of changing the distillation conditions of a binary mixture system by using an electrostatic field, which can solve the problems of low distillation efficiency and high energy consumption, and achieve the effects of increasing the distillation rate, strengthening the distillation separation, and improving the separation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

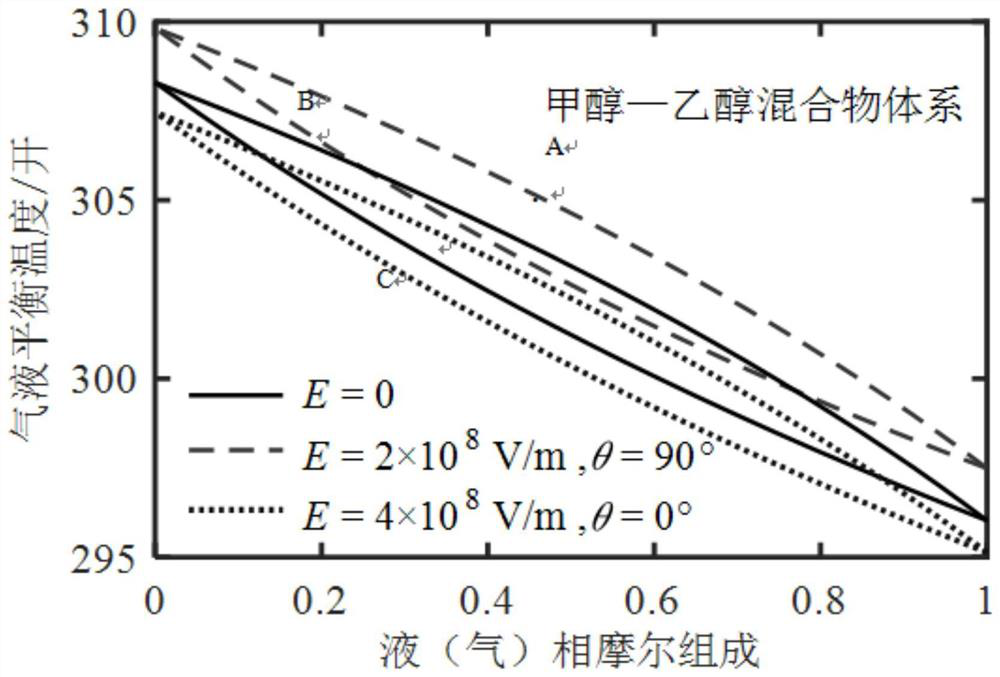

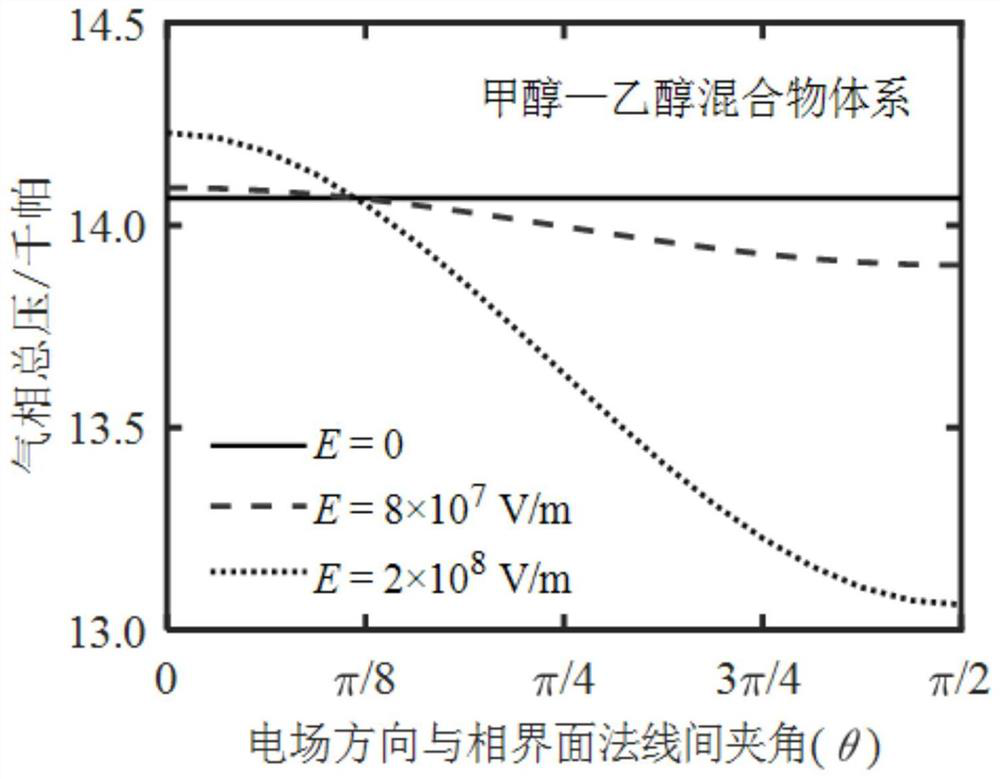

[0068] In this example, a methanol-ethanol binary mixture system is used for illustration.

[0069] The pressure is 15kPa, for the initial composition of the liquid phase x 1 =0.4 The mixture solution has a bubble point temperature of 302.46K and a dew point temperature of 304.30K when there is no electrostatic field. At an electric field strength of 8×10 7Under the action of V / m electrostatic field, when the angle between the applied direction of the electrostatic field and the phase interface is θ = 90°, that is, the direction of the electrostatic field is parallel to the phase interface, the bubble point temperature is 302.69K, an increase of 0.23K, an increase of 0.08%; dew point The temperature is 304.54K, an increase of 0.24K, an increase of 0.08%; when the angle between the direction of the electrostatic field and the phase interface is θ=0°, that is, the direction of the electrostatic field is perpendicular to the phase interface, the bubble point temperature is 302.4...

Embodiment 2

[0075] In this embodiment, the R32-R22 binary mixture system is selected for illustration.

[0076] The pressure is 200kPa, for the liquid phase initial composition x 1 =0.4 The mixed solution has a bubble point temperature of 241.98K and a dew point temperature of 243.50K without the action of an electrostatic field. At an electric field strength of 8×10 7 Under the action of V / m electrostatic field, when the angle between the applied direction of the electrostatic field and the phase interface is θ=90°, that is, when the direction of the electrostatic field is parallel to the phase interface, the bubble point temperature is 242.08K, an increase of 0.10K, an increase of 0.04%; dew point The temperature is 243.50K, an increase of 0.12K, an increase of 0.05%; when the angle between the direction of the electrostatic field and the phase interface is θ=0°, that is, the direction of the electrostatic field is perpendicular to the phase interface, the bubble point temperature is 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com