Ginger straw-based solid acid catalyst as well as preparation method and application thereof

A solid acid catalyst and ginger technology, applied in the direction of catalyst activation/preparation, carboxylic acid ester preparation, chemical instruments and methods, etc., to achieve the effects of easy recovery, low cost and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] A ginger straw-based solid acid catalyst for catalyzing esterification to produce biodiesel and a preparation method thereof, comprising the following steps:

[0024] 1) Wash the harvested ginger stalks to remove surface impurities and dry them at 105°C.

[0025] 2) Grinding and sieving the dried ginger stalks to 120 mesh (0.125 mm) to obtain ginger stalk powder.

[0026] 3) Take 10 g of ginger straw powder sieved in step 2) and carry out pyrolysis and carbonization in an inert atmosphere. The carbonization temperature is 300-500° C., and the carbonization time is 30-240 minutes.

[0027] 4) Take 4 g of the carbonized sample in step 3) and add 60 mL of concentrated sulfuric acid (95%-98%) for sulfonation reaction, and magnetically stir; the sulfonated product is fully filtered and washed with dewarmed deionized water until the filtrate is neutral , the filter cake was placed in a blast drying oven at 105° C. and dried to a constant weight to obtain a ginger straw-base...

Embodiment 1

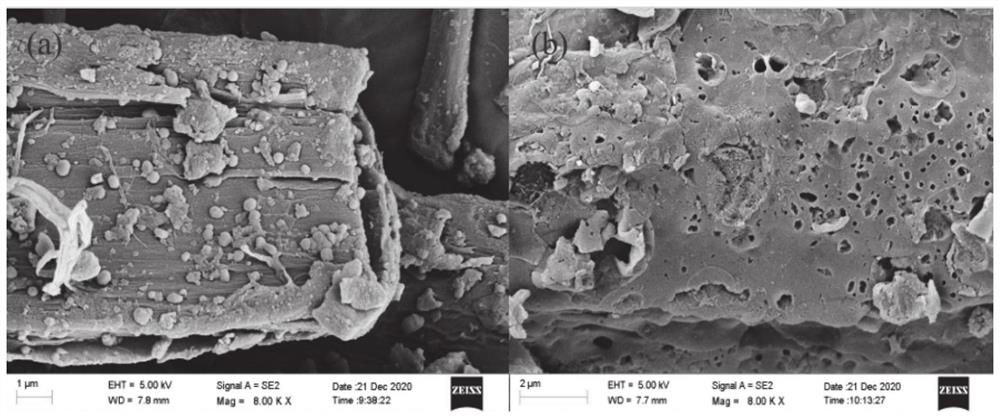

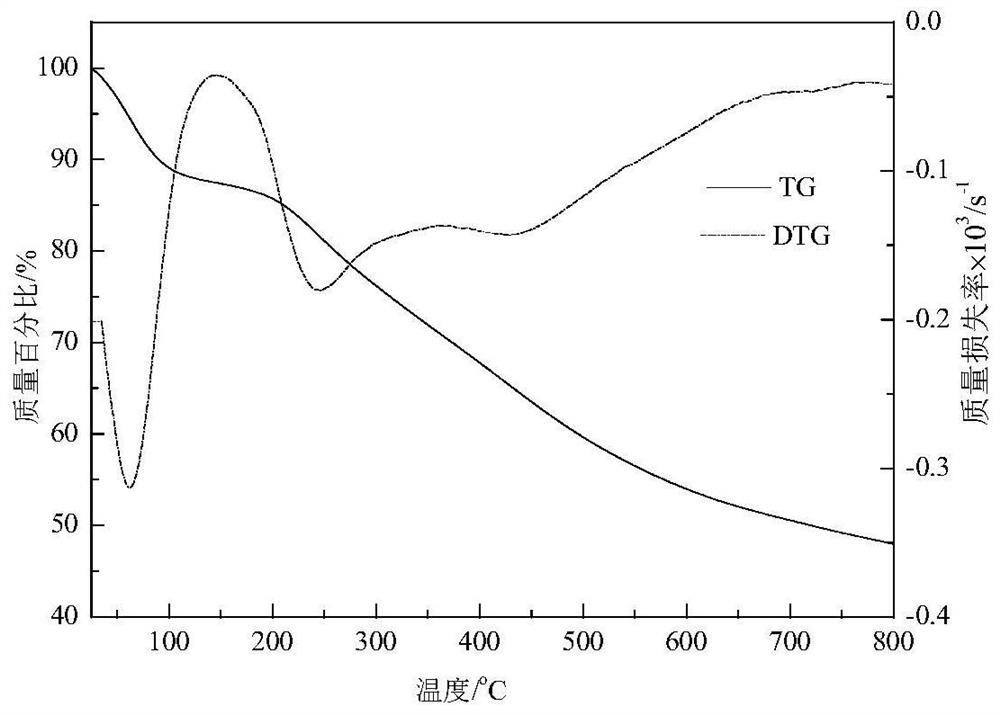

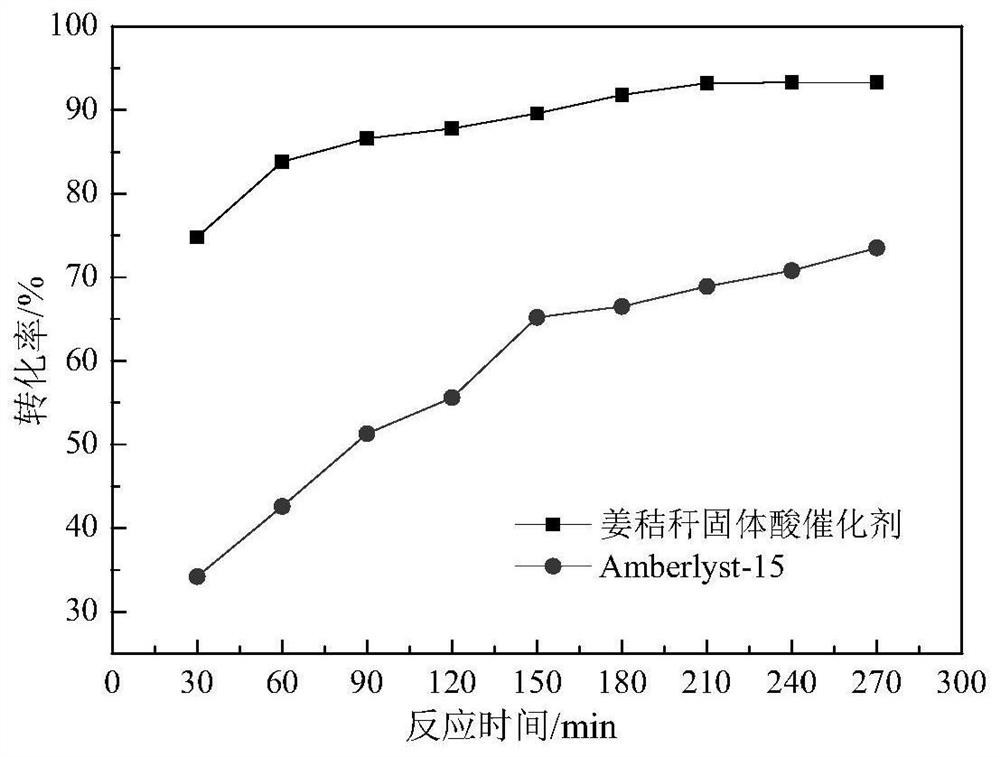

[0039]Ginger stalks collected from the field were washed to remove surface impurities, and dried in an oven at 105°C for later use. Grind and sieve the dried ginger stalks to 120 mesh (0.125 mm) to obtain powder; take 10 g of the sieved ginger stalk powder and place it in a program-controlled tube furnace, and heat up at a heating rate of 5 °C / min under an inert atmosphere. Maintain carbonization at 350°C for 120min; mix 4g of carbonized product with 60mL of concentrated sulfuric acid, and sulfonate at 105°C for 120min in a collector type constant temperature heating magnetic stirrer; after the reaction, cool the sulfonated product to room temperature and filter , washed repeatedly with warm deionized water until the filtrate was neutral; the obtained filter cake was dried in an oven at 105°C overnight to constant weight to obtain a ginger straw-based solid acid catalyst, and its acid density was measured based on the acid-base titration method It is 1.01 mmol / g.

[0040] In ...

Embodiment 2

[0042] Ginger stalks collected from the field were washed to remove surface impurities, and dried in an oven at 105°C for later use. Grind and sieve the dried ginger stalks to 120 mesh (0.125 mm) to obtain powder; take 10 g of the sieved ginger stalk powder and place it in a program-controlled tube furnace, and heat up at a heating rate of 5 °C / min under an inert atmosphere. Maintain carbonization at 400°C for 120min; mix 4g of carbonized product with 60mL of concentrated sulfuric acid, and sulfonate at 105°C for 120min in a collector type constant temperature heating magnetic stirrer; after the reaction, cool the sulfonated product to room temperature and filter , washed repeatedly with warm deionized water until the filtrate was neutral; the obtained filter cake was dried in an oven at 105°C overnight to constant weight to obtain a ginger straw-based solid acid catalyst, and its acid density was measured based on the acid-base titration method It is 0.97mmol / g.

[0043] In ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid density | aaaaa | aaaaa |

| Acid density | aaaaa | aaaaa |

| Acid density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com