Iron-loaded graphene-based tungsten disulfide nano lubricant additive and preparation method thereof

A technology of alkenyl tungsten disulfide and lubricants, which is applied in the direction of additives, lubricating compositions, petroleum industry, etc., can solve the problems of poor anti-wear performance and harsh preparation methods, and achieve improved extreme pressure wear resistance, less pollution, Effect of improving dispersibility and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

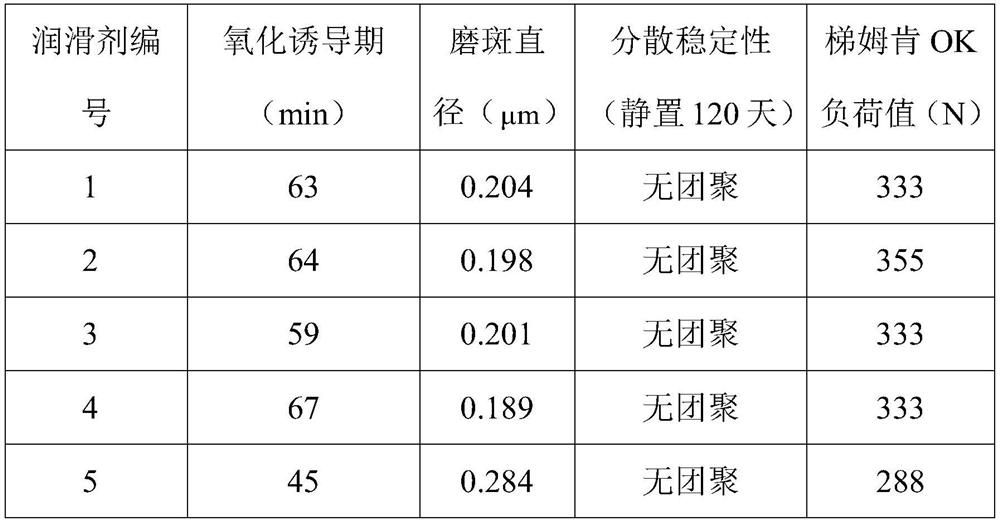

Examples

Embodiment 1

[0032] The present embodiment provides a preparation method of a graphene-based tungsten disulfide nano-lubricant additive loaded with iron, comprising the steps of:

[0033] S1: Dissolve sodium tungstate and thioacetamide in deionized water respectively to form an aqueous solution of sodium tungstate with a tungsten concentration of 40g / L and an aqueous solution of thioacetamide with a sulfur concentration of 32g / L, and then add 0.1L tungstic acid Sodium aqueous solution and 0.1L thioacetamide aqueous solution are mixed, and the mixed solution is adjusted to a pH value of 1 with hydrochloric acid aqueous solution;

[0034] S2: adding 0.8 g of graphene oxide to the solution in step S1, and ultrasonically treating it for 30 min at a frequency of 20 kHz and a power of 200 W to obtain a first suspension;

[0035] S3: Transfer the first suspension obtained in step S2 to a 100mL polytetrafluoroethylene autoclave, and move the autoclave to a heating box, and react for 36 hours at a ...

Embodiment 2

[0041] The present embodiment provides a preparation method of a graphene-based tungsten disulfide nano-lubricant additive loaded with iron, comprising the steps of:

[0042] S1: Dissolve sodium tungstate and thioacetamide in deionized water respectively to form an aqueous solution of sodium tungstate with a tungsten concentration of 36g / L and an aqueous solution of thioacetamide with a sulfur concentration of 30g / L, and then add 0.2L tungstic acid Sodium aqueous solution and 0.2L thioacetamide aqueous solution were mixed, and the mixed solution was adjusted to a pH value of 1 with aqueous hydrochloric acid;

[0043]S2: adding 0.7 g of graphene oxide graphene oxide into the solution in step S1, and ultrasonically treating it for 30 min under the conditions of a frequency of 20 kHz and a power of 200 W, to obtain a first suspension;

[0044] S3: Transfer the first suspension obtained in step S2 to a 100mL polytetrafluoroethylene autoclave, and move the autoclave to a heating bo...

Embodiment 3

[0050] The present embodiment provides a preparation method of a graphene-based tungsten disulfide nano-lubricant additive loaded with iron, comprising the steps of:

[0051] S1: Add ammonium tungstate and sodium sulfide to deionized water to fully dissolve respectively to form an aqueous ammonium tungstate solution with a tungsten concentration of 54g / L and an aqueous solution of sodium sulfide with a sulfur concentration of 30g / L, then add 0.12L ammonium tungstate solution and 0.24 L sodium sulfide aqueous solution is mixed, and mixed solution is adjusted to pH value 2 with nitric acid aqueous solution;

[0052] S2: adding 1.2 g of graphene oxide to the solution in step S1, and ultrasonically treating it for 20 min at a frequency of 20 kHz and a power of 200 W to obtain a first suspension;

[0053] S3: Transfer the first suspension obtained in step S2 to a 100mL polytetrafluoroethylene autoclave, and move the autoclave to a heating box, and react at a temperature of 170°C an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com