Underground high-sulfur mine air outlet shaft sulfur dioxide treatment method and device

A technology of sulfur dioxide and wind wells, applied in chemical instruments and methods, separation methods, and separation of dispersed particles, etc., can solve the problems of unsuitability to the actual situation of mine production, high resource consumption, and difficult implementation, and achieve high-efficiency desulfurization and dust removal, The process flow is reasonable and the effect of reducing system suspension and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0050] Example: The detection results of a west wind well in a high-sulfur copper mine show that the volume concentration of sulfur dioxide is 0.005%, and the air output of the west wind well is 100m3 / s, so the mass concentration of sulfur dioxide is about 13g / s.

[0051] According to above-mentioned detection result, calculate and use sodium carbonate lye amount:

[0052] Sodium carbonate=106*13 / 64=21.5g / s, that is, the hourly dosage is 77.4kg / h;

[0053] Water consumption: estimated about 31.5m 3 / h.

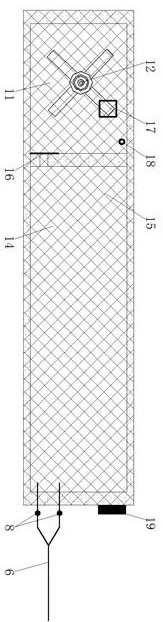

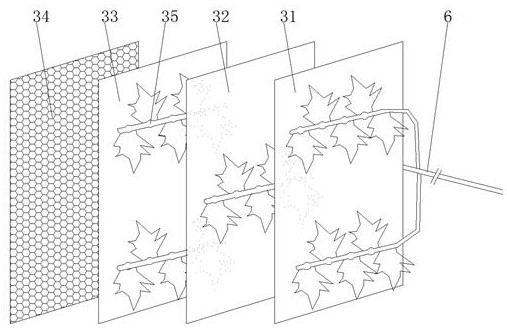

[0054] Sodium carbonate lye preparation system 1 is selected in the abandoned prospecting roadway 2 of No. 23 exploration line in the 568-meter middle section of the mine. The prospecting roadway is 3.8 meters wide and 3.4 meters high. The lye spray system 3 is installed on No. 23 to No. 24 exploration lines In the straight main air return roadway 4, see Figure 4 .

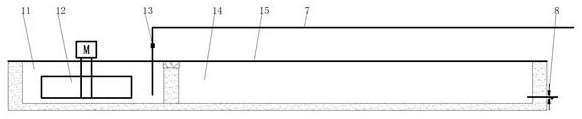

[0055] In this example, if figure 1 As shown, between the preparation pool 11 and the storage pool 14, a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com