Reinforcing agent for reinforcing biofilm formation of waste gas biofiltration device and application thereof

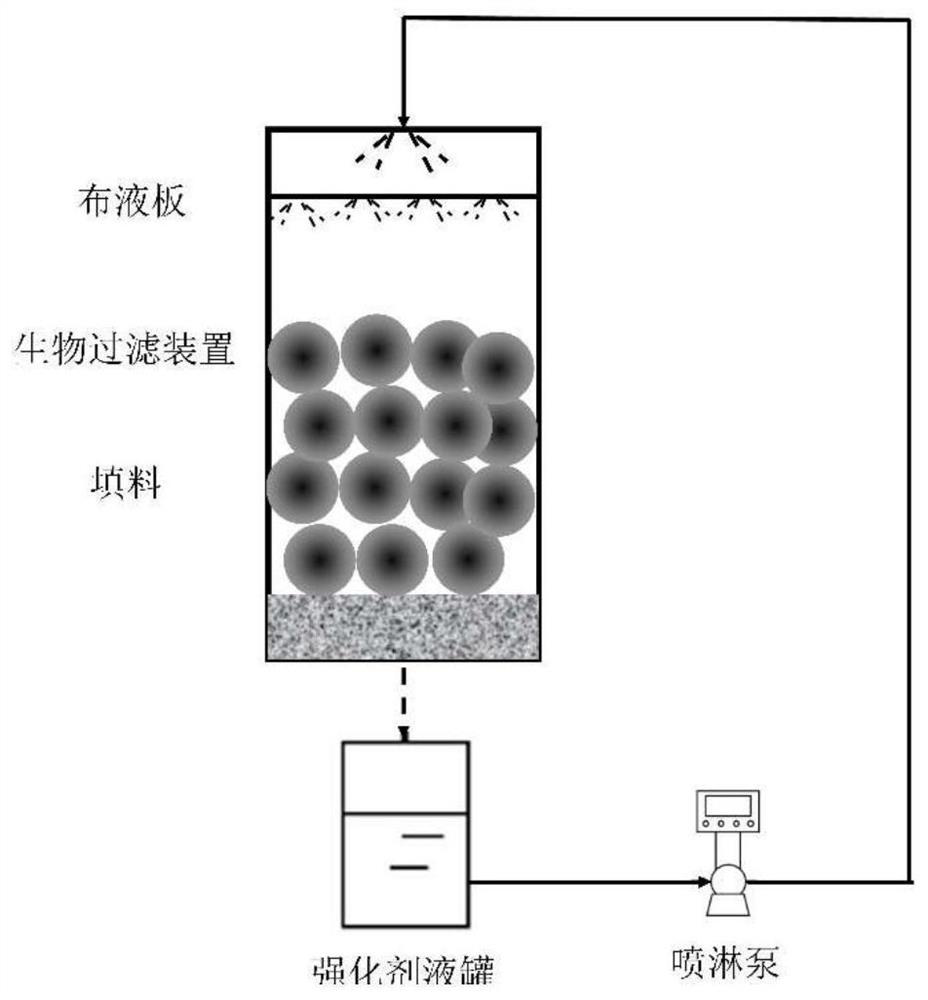

A technology of biological filtration and strengthening agent, applied in the field of environmental management, can solve the problems of slow startup of biological filtration devices, and achieve the effects of shortening the startup time of film hanging, convenient and reasonable use, and shortening the startup cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-9

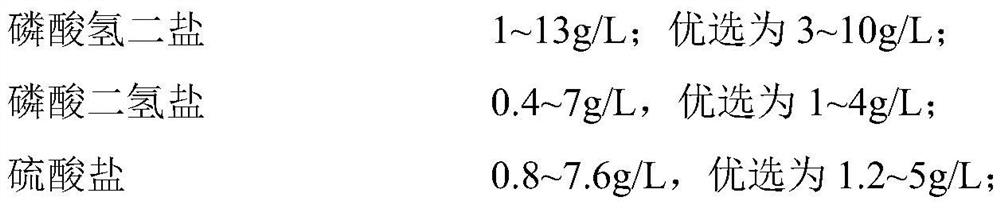

[0047] In the following embodiments, if there is no particular purpose, the reinforcing agent of the exhaust gas biofiltration device is formulated as follows:

[0048] 1. High rhythritis is dissolved in a methanol solution to obtain the acyl-high rhythutide concentrate; the concentration of the high rhythutide concentrate is 800 mg / L.

[0049] 2. The substance is dissolved in ultra-pure water according to the required mass concentration to form a nutrient salt solution.

[0050] 3. The resulting high rhythutide concentrate is dissolved in a nutrient salt solution to obtain a reinforcing agent solution.

Embodiment 1

[0052] Examples 10-15 are substantially identical to those of Example 1, and differ only in: the concentration of copper sulfate in the reinforcing agent is different.

Embodiment 16

[0054] Example 16 is substantially the same as that of Example 1, the difference is only that only an acyl group high rhythutide and copper copper in the strengthening agent are contained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com