A kind of polyvinyl chloride plasticizing antistatic agent and preparation method thereof

A technology of polyvinyl chloride and plasticizing resistance is applied in the field of fine chemical additives, which can solve the problems of large energy consumption, high equipment investment and single function in the preparation process, so as to save the cost of adding additives, ensure quality stability, reduce The effect of the process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

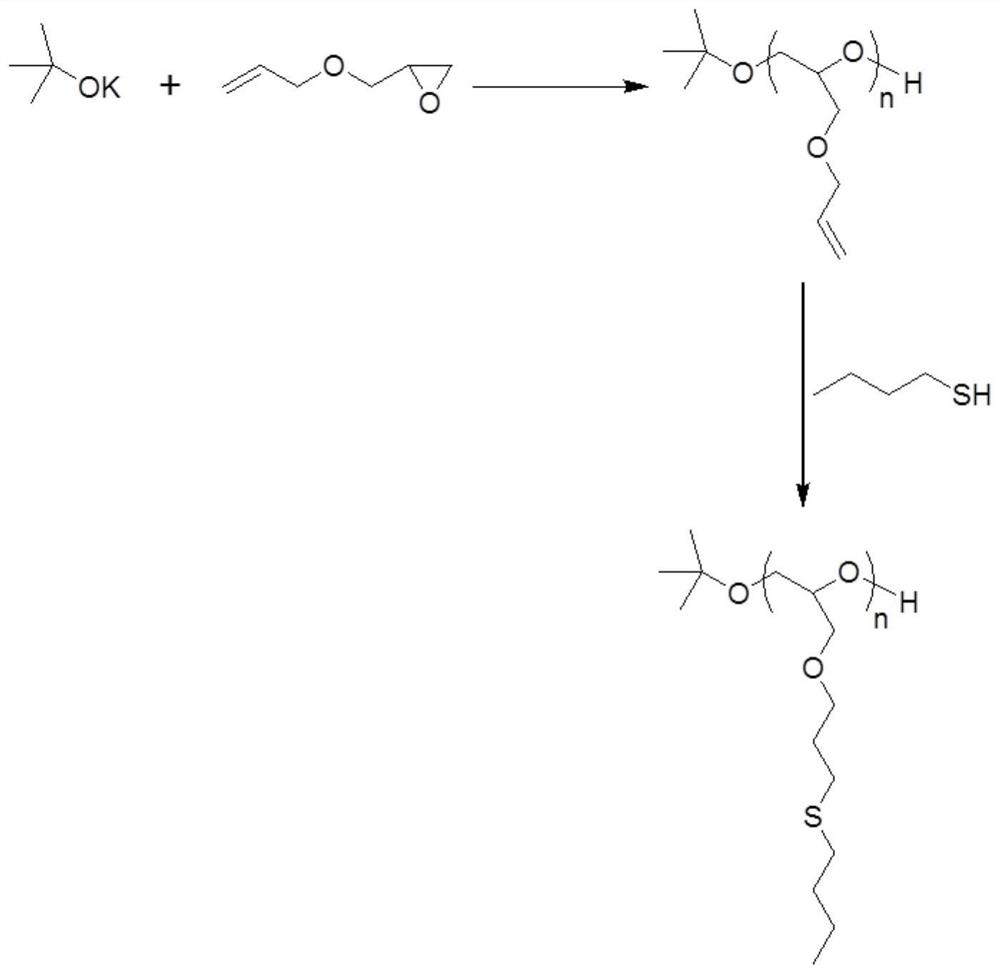

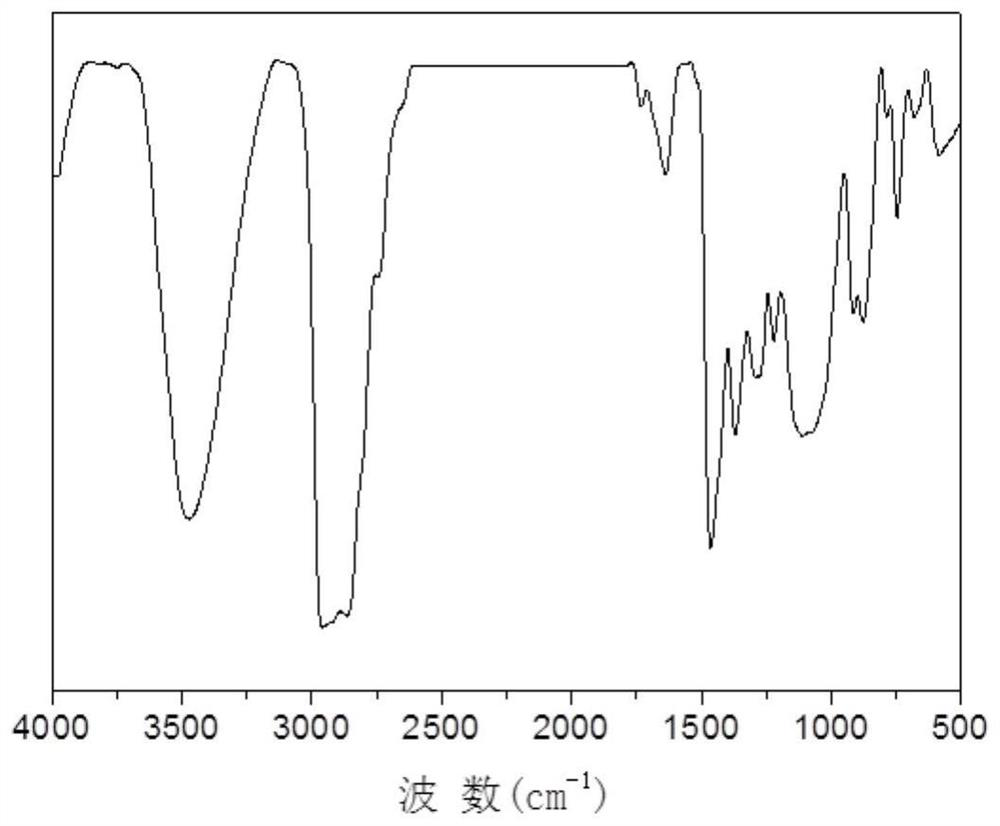

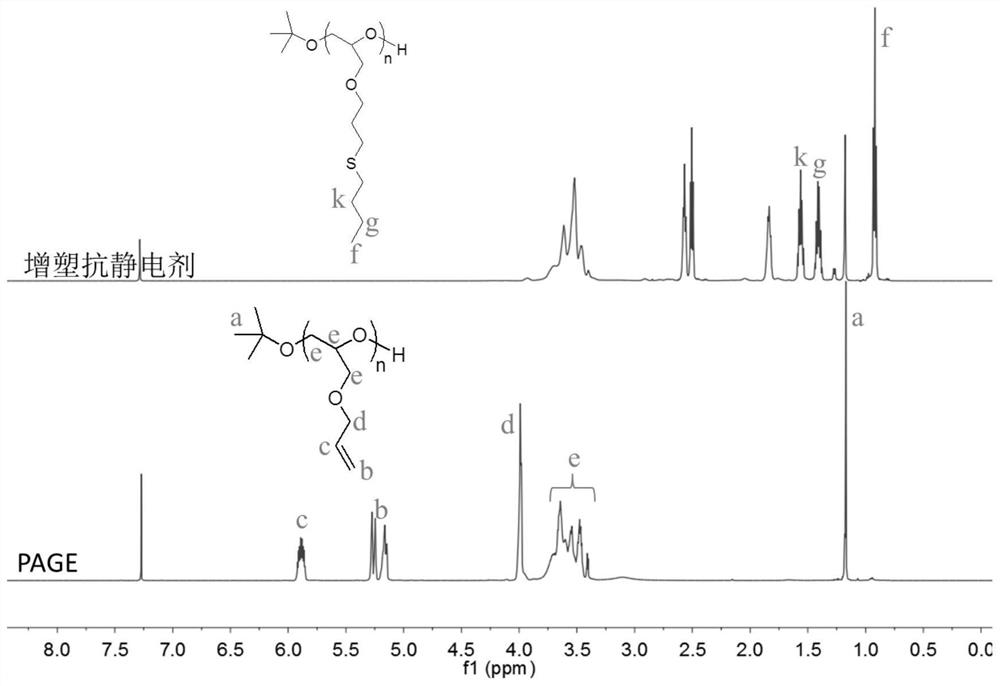

[0030] This embodiment provides a polyvinyl chloride plasticizing antistatic agent, which is prepared by the following method:

[0031] (1) Dissolve 0.6 g of potassium tert-butoxide and 6 g of allyl glycidyl ether in anhydrous tetrahydrofuran. The solution was left to polymerize at 60°C for 24 hours. After that, hydrochloric acid was added to the system to terminate the polymerization reaction. The precipitate was removed by filtration. Using a rotary evaporator to remove the organic solvent, a polyallyl glycidyl ether (PAGE) intermediate product was obtained.

[0032] (2) 2.5 g of the above-mentioned intermediate product PAGE, 4 g of n-butanethiol, 8.12 mg of ruthenium terpyridine chloride and 73.63 mg of p-toluidine were dissolved in N-methylpyrrolidone. The solution was left at room temperature and irradiated with blue light for 0.5 hours to complete the reaction. After the reaction, unreacted n-butanethiol, solvent and catalyst were removed by dialysis in ethanol. Usi...

Embodiment 2

[0034] This embodiment provides a polyvinyl chloride plasticizing antistatic agent, which is prepared by the following method:

[0035] (1) Dissolve 0.6 g of potassium tert-butoxide and 3 g of allyl glycidyl ether in anhydrous tetrahydrofuran. The solution was allowed to polymerize at 60°C for 2 hours. After that, sulfuric acid was added to the system to terminate the polymerization reaction. The precipitate was removed by filtration. Using a rotary evaporator to remove the organic solvent, a polyallyl glycidyl ether (PAGE) intermediate product was obtained.

[0036] (2) 2.5 g of the above-mentioned intermediate product PAGE, 2 g of n-butanethiol, 8.12 mg of ruthenium terpyridine chloride and 73.63 mg of p-toluidine were dissolved in N,N-dimethylformamide. The solution was left at room temperature and irradiated with blue light for 0.5 hours to complete the reaction. After the reaction, unreacted n-butanethiol, solvent and catalyst were removed by dialysis in ethanol. Usi...

Embodiment 3

[0038] This embodiment provides a polyvinyl chloride plasticizing antistatic agent, which is prepared by the following method:

[0039] (1) 0.6 g of potassium tert-butoxide and 60 g of allyl glycidyl ether were dissolved in anhydrous toluene. The solution was left to polymerize at 40°C for 24 hours. After that, phosphoric acid was added to the system to terminate the polymerization reaction. The precipitate was removed by filtration. Using a rotary evaporator to remove the organic solvent, a polyallyl glycidyl ether (PAGE) intermediate product was obtained.

[0040] (2) 2.5 g of the above intermediate product PAGE, 5 g of n-butanethiol, 8.12 mg of ruthenium terpyridine chloride and 73.63 mg of p-toluidine were dissolved in ethanol. The solution was left at room temperature and irradiated with blue light for 2 hours to complete the reaction. After the reaction, unreacted n-butanethiol, solvent and catalyst were removed by dialysis in ethanol. Using rotary evaporation to re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com