Low-odor biodegradable PLA alloy applied to food contact field and preparation method of low-odor biodegradable PLA alloy

A food contact, low-odor technology, applied in the direction of biological packaging, climate sustainability, sustainable manufacturing/processing, etc., can solve the problems that have not been discovered yet, reduce odor, and use high temperature, so as to avoid uneven dispersion and overall odor Low, good compatibility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

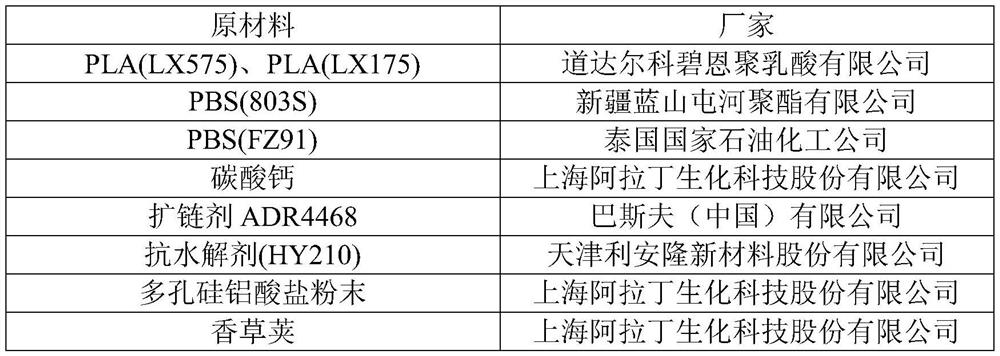

Method used

Image

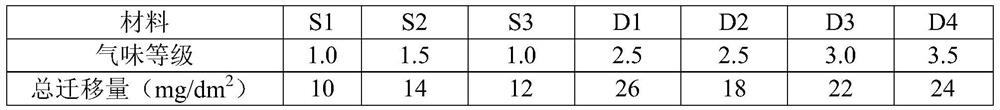

Examples

Embodiment 1

[0049] (1) Prepare vanilla extract

[0050]Weigh 50g of vanilla pods into a flask, add 450mL of ethanol, heat in a constant temperature water bath, install a reflux device, set the temperature of the water bath to 70°C, and heat for 15 hours; filter and collect the clarified extract.

[0051] (2) Preparation of flavor modified porous silicon aluminum

[0052] Weigh 18g of porous aluminosilicate powder and add it to 200mL of the above extract, heat it in a constant temperature water bath, install a reflux device, and adjust the pH to 4-5 with dilute hydrochloric acid. ℃, heating and reacting for 8 hours, pour the mixed liquid into a vacuum drying tray, and vacuum-dry at 100 ℃ for 4 hours to prepare the fragrance-modified porous silica-alumina.

[0053] (3) With essence modified porous silicon aluminum and the formula component in table 1 as raw material, and with reference to the raw material consumption in table 1, prepare PLA alloy according to the following method:

[0054...

Embodiment 2

[0059] (1) Prepare vanilla extract

[0060] Weigh 50g of vanilla pods into a flask, add 400mL of ethanol, heat in a constant temperature water bath, install a reflux device, set the temperature of the water bath to 60°C, and heat for 12.5h; filter and collect the clarified extract.

[0061] (2) Preparation of flavor modified porous silicon aluminum

[0062] Weigh 14g of porous aluminosilicate powder and add it to 200mL of the above extract, heat it in a constant temperature water bath, install a reflux device, and adjust the pH to 4-5 with dilute hydrochloric acid. ℃, heating and reacting for 7 hours, pouring the mixed liquid into a vacuum drying tray, and drying in vacuum at 90 ℃ for 2 hours to obtain flavor-modified porous silica-alumina.

[0063] (3) With essence modified porous silicon aluminum and the formula component in table 1 as raw material, and with reference to the raw material consumption in table 1, prepare PLA alloy according to the following method:

[0064] ...

Embodiment 3

[0069] (1) Prepare vanilla extract

[0070] Weigh 50g of vanilla pods into a flask, add 350mL of ethanol, heat in a constant temperature water bath, install a reflux device, set the temperature of the water bath to 50°C, and heat for 18 hours; filter and collect the clarified extract.

[0071] (2) Preparation of flavor modified porous silicon aluminum

[0072] Weigh 7g of porous aluminosilicate powder and add it to 200mL of the above extract, heat it in a constant temperature water bath, install a reflux device, and adjust the pH to 4-5 with dilute hydrochloric acid. ℃, heating and reacting for 6 hours, pouring the mixed solution into a vacuum drying tray, and drying in vacuum at 80 ℃ for 1 hour to prepare the fragrance-modified porous silica-alumina.

[0073] (3) With essence modified porous silicon aluminum and the formula component in table 1 as raw material, and with reference to the raw material consumption in table 1, prepare PLA alloy according to the following method:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com