Modified asphalt and preparation method thereof

A technology of modified asphalt and matrix asphalt, applied in building components, building insulation materials, construction and other directions, can solve the problems of large density difference, difficult compaction, difficult mixing of modified asphalt, etc., and achieve reasonable and easy viscosity. Mixing and compaction, excellent pavement performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

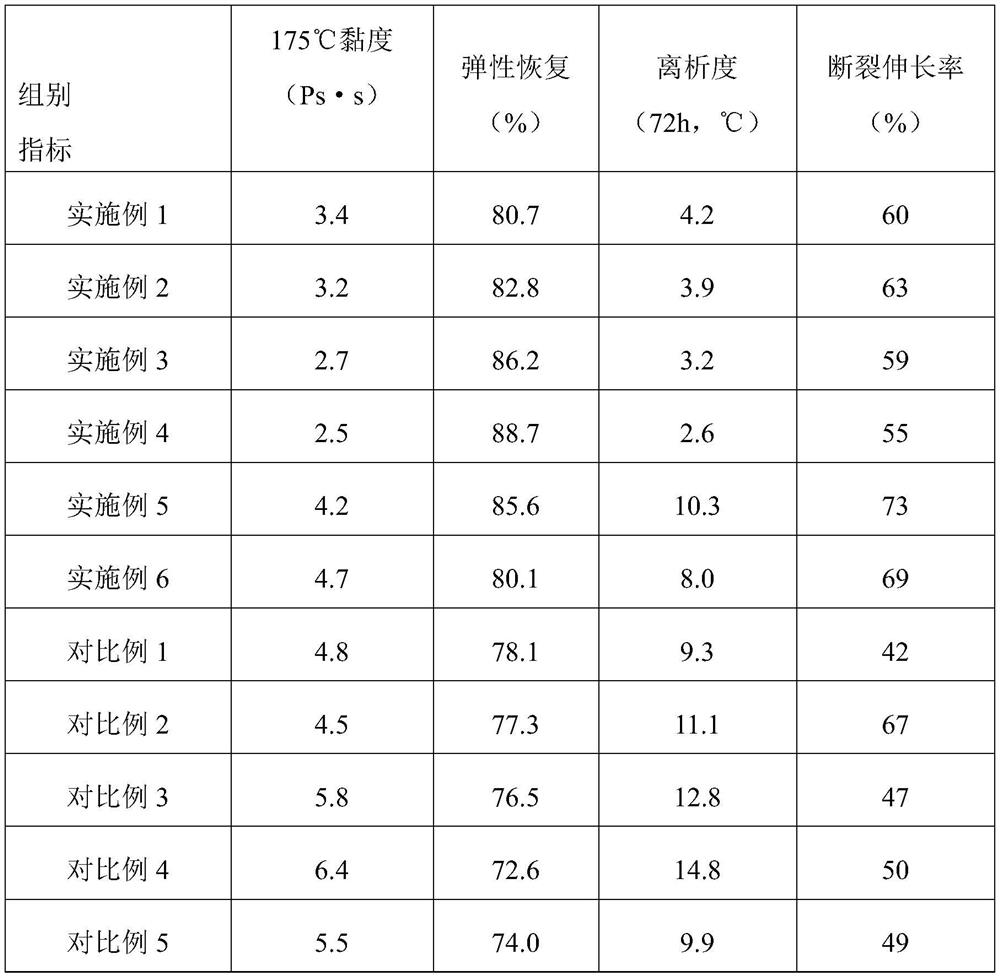

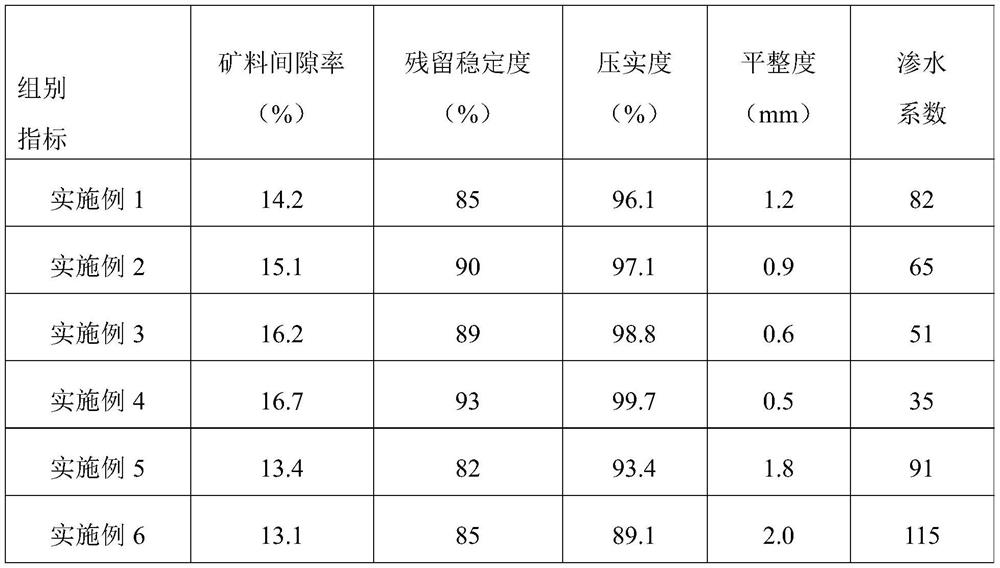

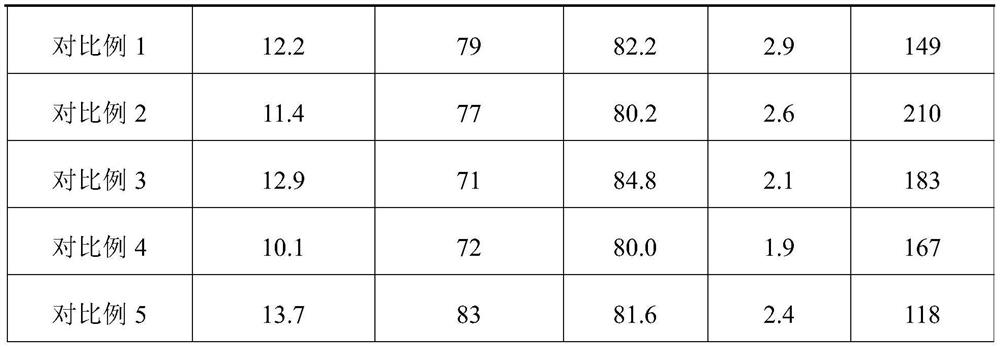

Examples

Embodiment 1

[0026] A kind of modified asphalt, comprises the raw material of following weight: base asphalt 125kg, 50 order rubber powder 15kg, furfural extract oil 5kg, epoxy resin 5kg, diluent 5kg, curing agent 3kg and silicone resin (stabilizer) 6kg; The diluent is mixed with 1kg of ethylene glycol diglycidyl ether, 2kg of propylene oxide butyl ether and 2kg of xylene; the curing agent is mixed with 1kg of polyetheramine, 1.5kg of diethylenetriamine and 0.5kg of triethylamine made.

Embodiment 2

[0028] A kind of modified asphalt, comprises the raw material of following weight: base asphalt 150kg, 40 order rubber powder 50kg, furfural extract oil 10kg, epoxy resin 15kg, diluent 10kg, curing agent 8kg and silicone resin (stabilizer) 12kg; The diluent is made by mixing 3kg of ethylene glycol diglycidyl ether, 3kg of propylene oxide butyl ether and 4kg of xylene; the curing agent is made by mixing 4kg of polyetheramine, 3kg of diethylenetriamine and 1kg of triethylamine .

Embodiment 3

[0030] A kind of modified asphalt, comprises the raw material of following weight: base asphalt 140kg, 35 mesh rubber powder 35kg, furfural extract oil 8kg, epoxy resin 12kg, diluent 8kg, curing agent 6kg and silicone resin (stabilizer) 8kg; The diluent is mixed by ethylene glycol diglycidyl ether 1.5kg, propylene oxide butyl ether 3kg and xylene 3.5kg; the curing agent is made of polyetheramine 3kg, diethylenetriamine 2.2kg, triethylamine 0.8 kg mixed.

[0031] According to the raw material of modified asphalt in above-mentioned embodiment 1~3, its preparation method comprises the steps:

[0032] S1 Weigh the raw materials according to the weight of the formula, heat and melt the base asphalt at 190°C, and add rubber powder and furfural to extract oil during the heating process to obtain a mixed solution 1, the amount of rubber powder added is 40% of the weight of the formula;

[0033] S2 Shear the mixed solution 1 at a shear rate of 3000rpm for 40min, mix the epoxy resin an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com