Pile hole water abrasive drill construction method for karst area

A technology of water mill drilling and pile hole, which is applied in drilling equipment and methods, underground chambers, earthwork drilling, etc. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with specific examples.

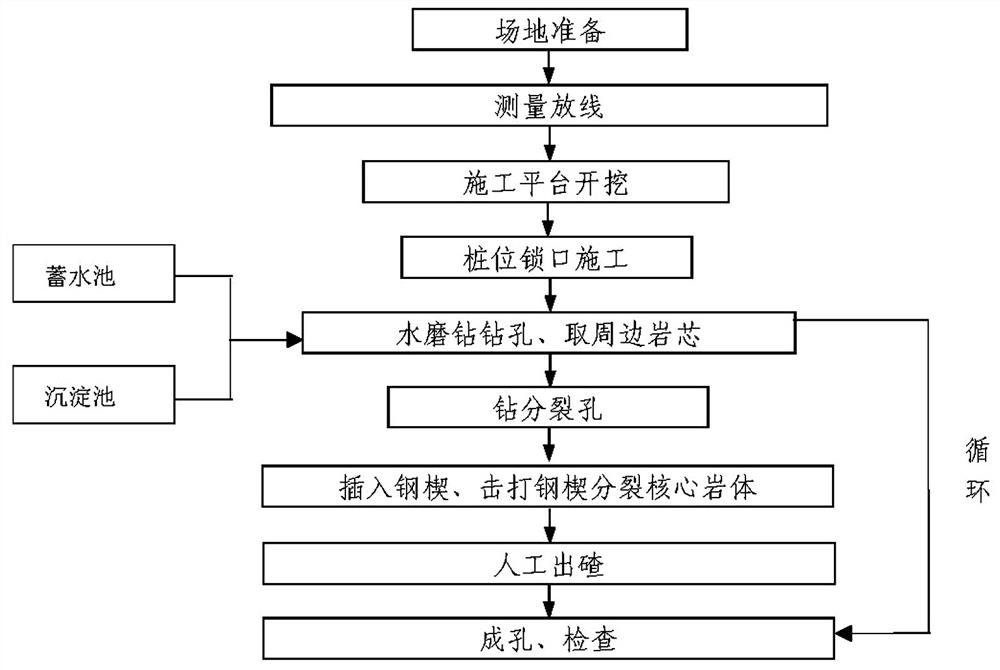

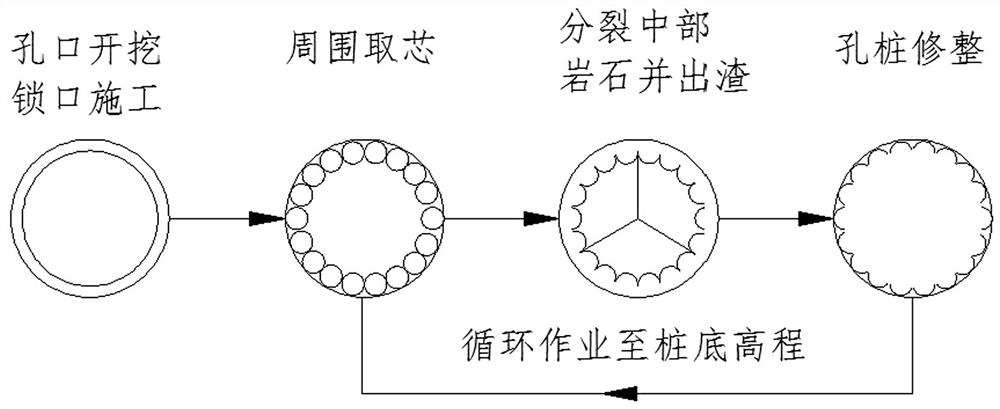

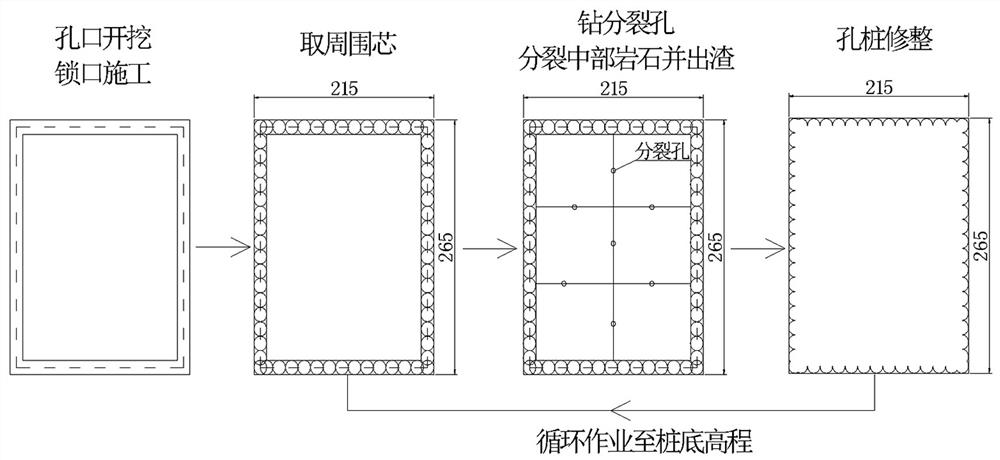

[0032] A construction method of pile hole water mill drilling in karst areas, such as figure 1 The flow chart shown includes the following steps:

[0033] 1. Pre-construction process:

[0034] (1) Construction preparation: connect the water source and power supply, transport the materials and equipment required for construction in place, prepare the design drawings, and understand the relevant parameters of geological conditions, column diameters, and depths, and provide technical and safety disclosures to the operators , to meet the start-up conditions;

[0035] (2) Surveying and setting out: use the total station to accurately release the position of the anti-slide pile hole, and set up the protective pile so as to control the position of the pile hole during the construction process;

[0036] (3) Excavation of the construction platform: After measuring the pier position ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com