Sodium fluid heat energy power generation device and method for converting heat energy into electric energy by using sodium fluid heat energy power generation device

A thermal power generation and fluid technology, which is applied to generators, generators/motors, and electrical components that convert kinetic energy into electrical energy. Efficiency, the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

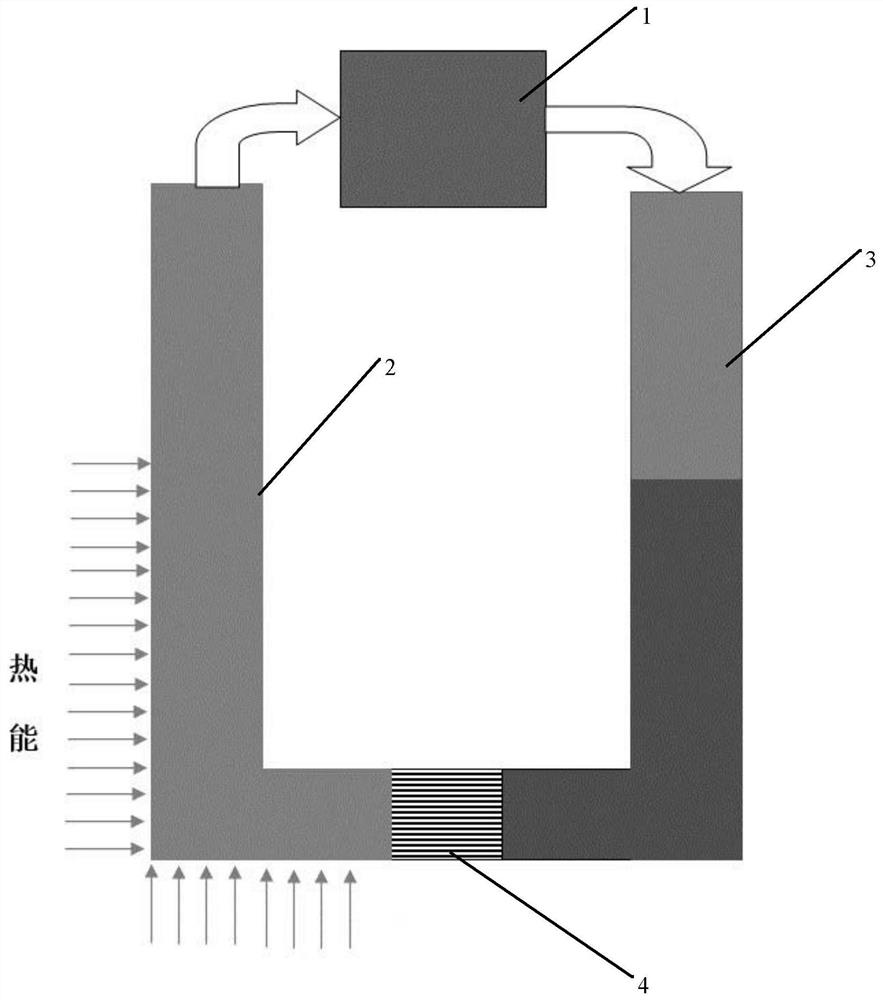

[0042] Taking the heat source provided by a high-temperature gas-cooled nuclear reactor as an example, the figure 1 The shown sodium fluid thermal power generation device of the present invention provides a heat source of 950 degrees, and the device includes a sodium fluid concentration battery stack 1, a heat exchanger, a high-pressure sodium fluid pipeline 2, a low-pressure sodium fluid pipeline 3 and a capillary pump 4, and the sodium fluid The working medium 5 circulates in closed loop.

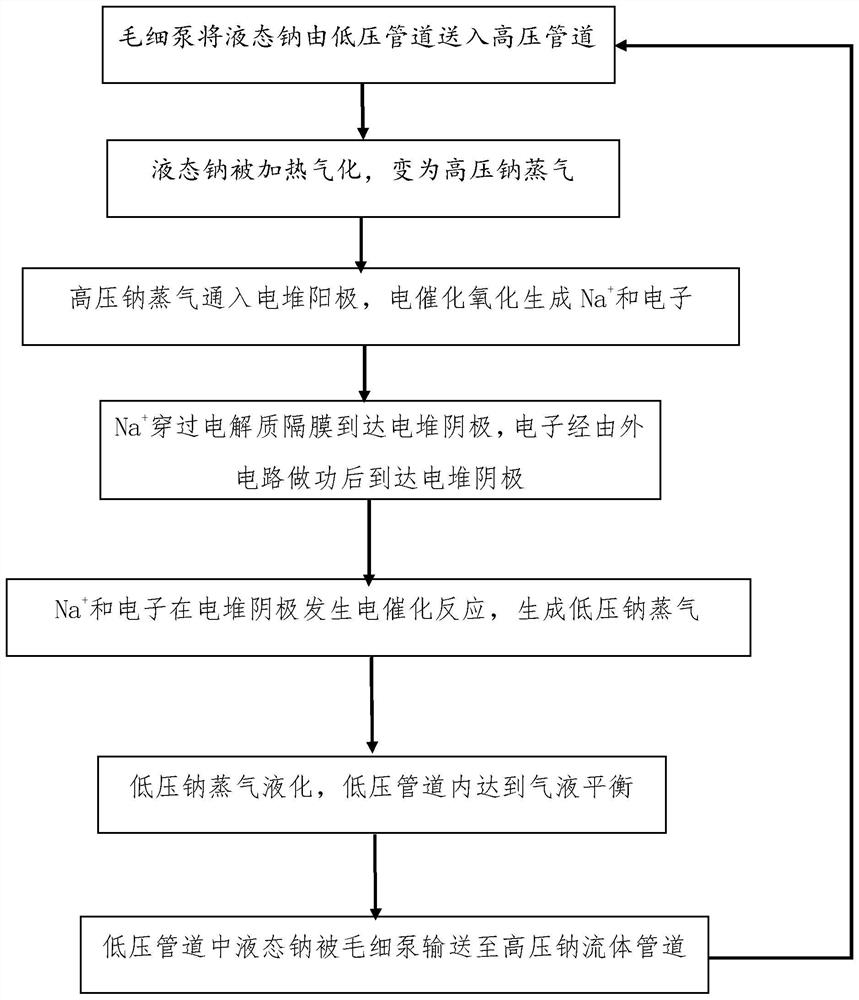

[0043] The process of using this device to convert heat energy into electrical energy is as follows: figure 2 Shown:

[0044] The first step: the capillary pump pumps liquid sodium from the low-pressure sodium fluid pipeline to the high-pressure sodium fluid pipeline;

[0045] Step 2: Liquid sodium is heated and vaporized in the high-pressure sodium fluid pipeline to increase the pressure and become high-pressure sodium vapor;

[0046] Step 3: High-pressure sodium vapor is passed into...

Embodiment 2

[0053] Taking the heat source provided by concentrated solar energy as an example, the figure 1 The shown sodium fluid thermal power generation device provides a heat source at 900°C, and the low temperature end of the sodium fluid thermal power generation device is 200 degrees. Through the Nernst equation, the open circuit voltage of the sodium concentration battery of the fluid thermal power generation device can be calculated to be about 1.8V. The lower current density is 0.9A / cm2, the active area of 1 square meter can output about 10.8kW (operating voltage is 1.2V), and 100 series stacking is 1.08MW. In terms of efficiency, for the sodium concentration battery, the electrochemical polarization, ohmic polarization, and concentration polarization are all greatly reduced at high temperature, and the electric energy conversion efficiency η of the concentration battery is defined e It is the ratio of the output electric energy of the battery to the Gibbs free energy change △G...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com