High-temperature resourceful disposal method of aluminum electrolytic waste tank lining

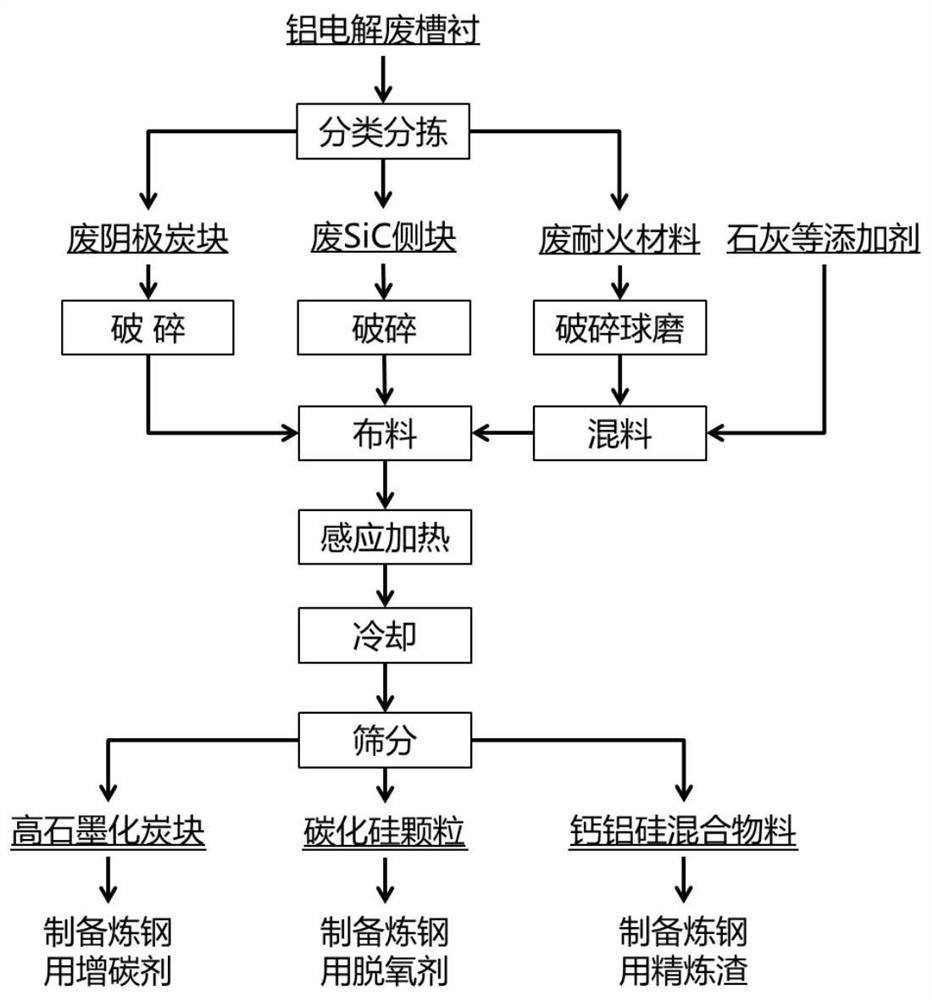

A waste tank lining and recycling technology, applied in chemical instruments and methods, solid waste removal, transportation and packaging, etc., can solve problems such as poor economy, unusable solid waste, and inability to meet environmental protection requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0039] A method for harmless disposal and resource utilization of waste liners of aluminum electrolytic cells, comprising the following steps:

[0040] 1. Prepare 100g of spent cathode carbon blocks with a particle size of 30-35mm, 25g of waste silicon carbide with a particle size of 1mm, 100g of waste refractory materials with a particle size of less than 100μm and 100g of calcium oxide powder mixed covering material;

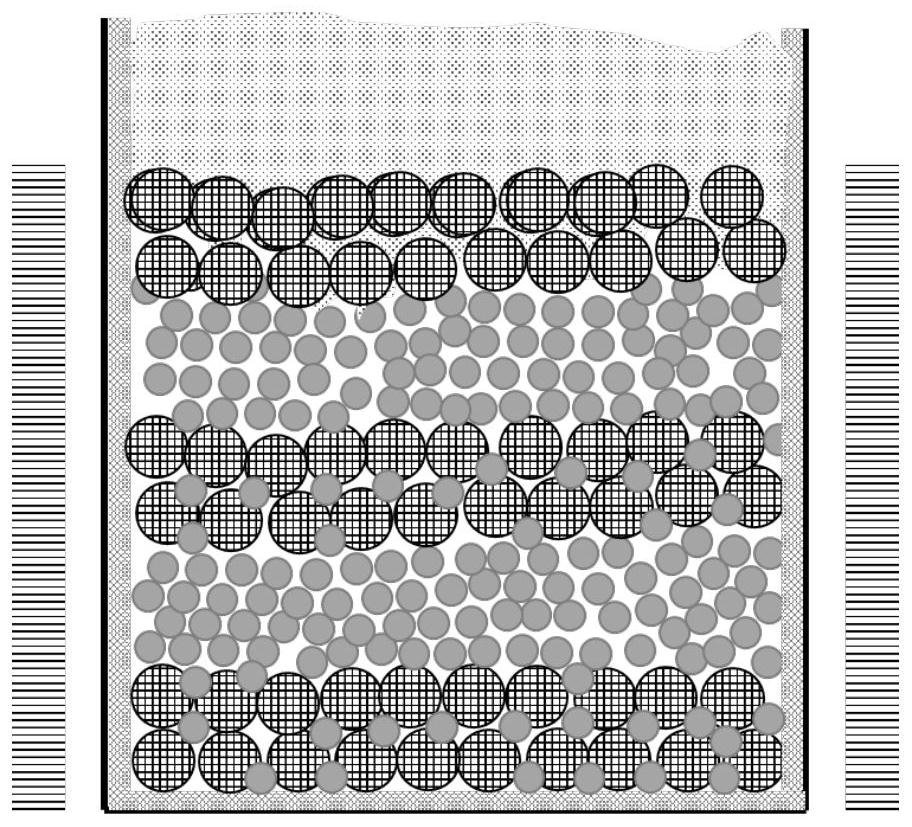

[0041] 2. Prepare a corundum crucible with a wall thickness of 5mm, an inner diameter of 80mm, and a height of 200mm and a calcium oxide crucible with a wall thickness of 5mm, an inner diameter of 70mm, and a height of 190mm; place the calcium oxide crucible in the corundum crucible;

[0042] 3. From bottom to top, add the materials into the prepared crucible in the order of 50g waste carbon block, 25g waste silicon carbide particles, 50g waste carbon block, and 200g covering material, and place the crucible in an induction heating coil. The waste carbon block...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com