Double-deflection light beam shaping device for concave surface forming grinding wheel and machining method

A technology for deflecting beams and shaping grinding wheels, applied in abrasive surface adjustment devices, metal processing, metal processing equipment, etc., can solve the problems affecting the application of laser dressing technology on the concave surface of super-hard abrasive grinding wheels, the inconsistency of the concave surface contour, and the poor dressing quality. problems, to achieve the effect of improving dressing efficiency, speeding up forming and improving dressing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

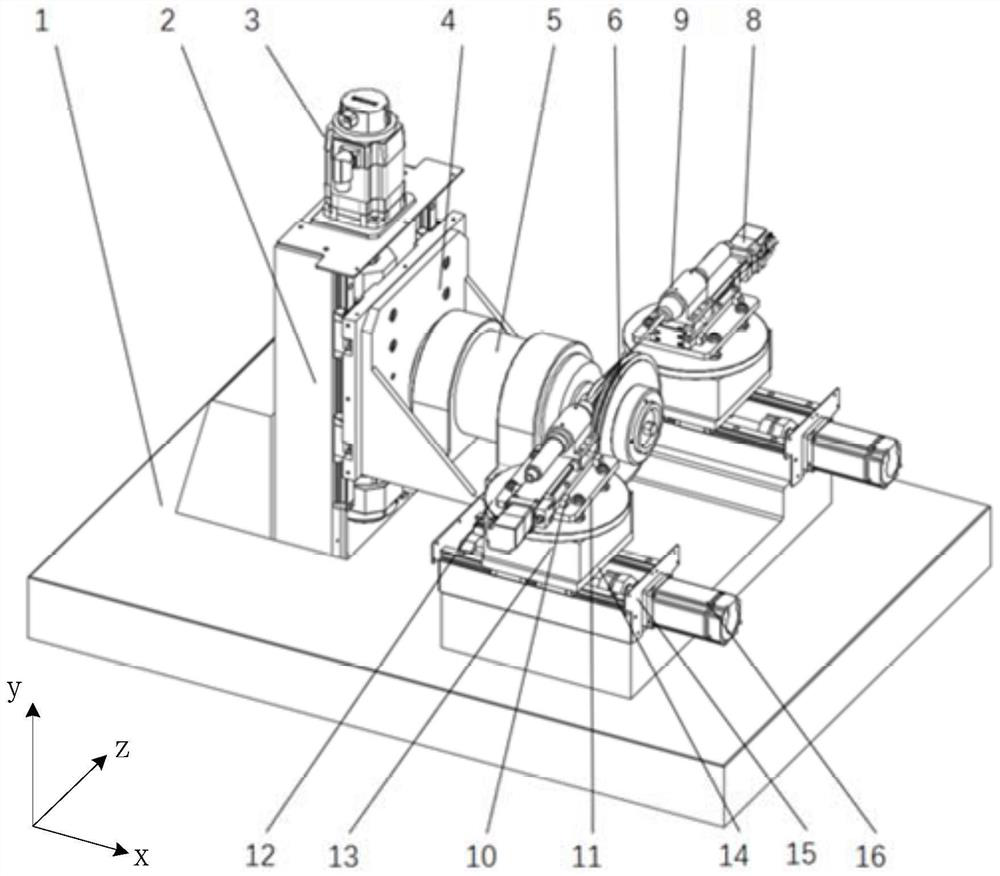

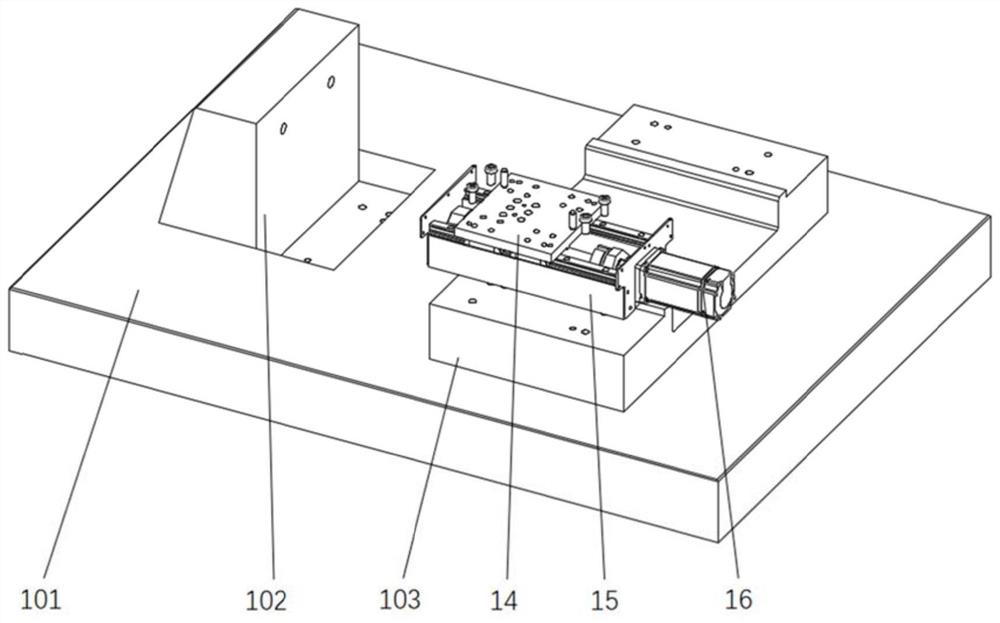

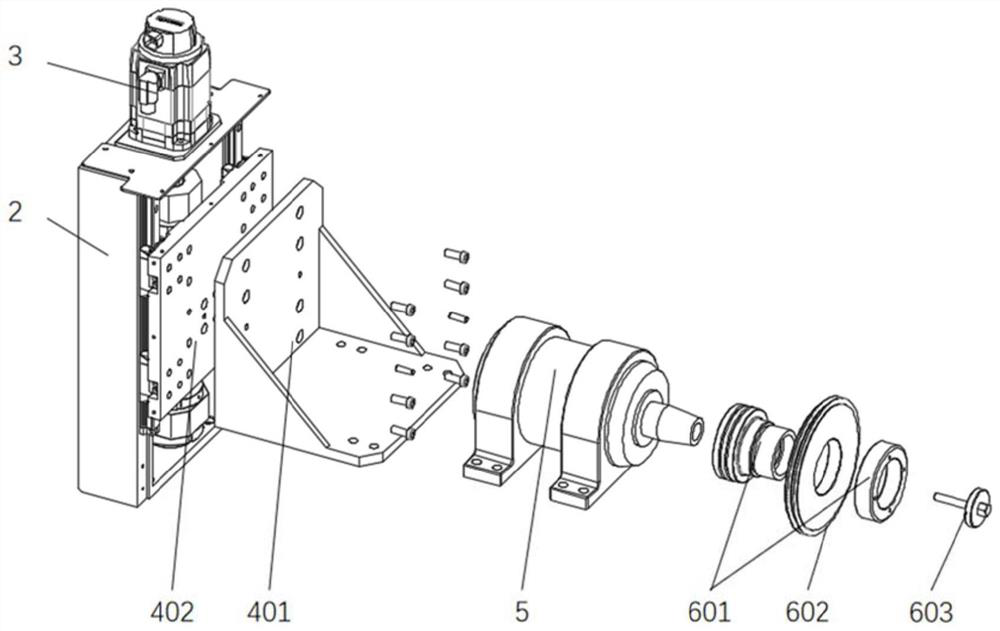

[0040] Such as figure 1 As shown, this embodiment provides a double-deflection beam shaping device for concave shaped grinding wheels, which includes: a support base assembly 1, a vertical displacement motion table 2, and a deflection laser trimming device; establish xyz three-system coordinate axes, set The direction of the x-axis is the horizontal direction, the direction of the y-axis is the vertical direction, and the direction of the z-axis is the front-back direction. The vertical displacement motion table 2 is used to adjust the height of the concave grinding wheel 602 to be trimmed thereon, so as to adjust the depth of cut.

[0041] The deflection laser trimming devices are arranged on the left and right sides of the vertical displacement motion table 2 respectively, on which a laser is arranged, and by adjusting the deflection angle of the laser on it, the double deflection beam shaping of the concave surface of the concave grinding wheel 602 to be trimmed is realized...

Embodiment 2

[0064] Such as Figure 5 As shown, on the basis of the above embodiments, this embodiment provides a processing method for trimming a concave grinding wheel using the double deflection beam shaping device for concave forming grinding wheels described in the above embodiments, the method includes:

[0065] Step 1, adjust the deflection laser trimming devices on the left and right sides, so that the laser beams emitted by the laser head 7 on the deflection laser trimming devices on both sides are in the same horizontal state;

[0066] Specifically, the shaping processing method in this embodiment can be realized through cooperation between the numerical control system and the device in the first embodiment above, and the numerical control system is used to control each motor.

[0067] The laser head 7 in this embodiment is a nanosecond laser pulse laser head. The deflection laser trimming device may include a laser center adjustment block 10 and a laser level adjustment assembl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com