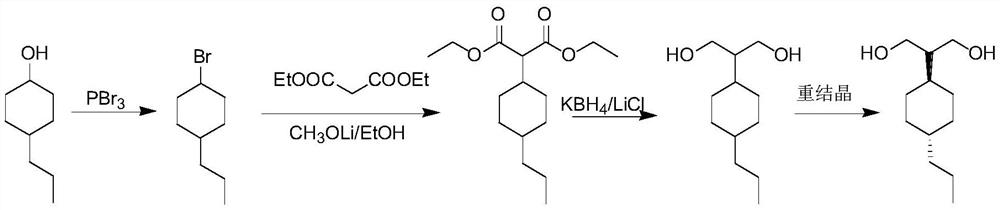

Preparation method of 2-(trans-4-n-propyl cyclohexyl) propane-1, 3-diol

A technology of n-propyl and cyclohexane, applied in the field of preparation of 2-propane-1,3-diol, can solve problems such as dangerous processes, and achieve the effects of reducing side reactions, low cost and improving the yield of reduction reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The molar ratio of 1-bromo-4-n-propylcyclohexane, lithium methylate and diethyl malonate is 1:1.1:2, the reaction system is lithium methylate / ethanol, and the amount of substance in the ethanol solution of lithium methylate The concentration is 1.2mol / L.

[0028] Before feeding, make sure that the reactor is clean and dry, protect it with nitrogen, add 392Kg of ethanol to the reactor, start stirring, add 22.6Kg of lithium methoxide into the reactor, start the temperature rise, turn on the reflux device, and control the temperature between 45-50°C 170Kg of diethyl malonate was added dropwise to the reaction kettle using a dropping kettle, and the reaction temperature was controlled between 50-55°C during the dropping process. After the dropping was completed, the stirring was continued for 30 minutes; Add 109Kg of 1-bromo-4-n-propylcyclohexane dropwise to the reactor, and control the reaction temperature between 50-55°C during the dropwise addition. After the dropwise ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com