Nano magnesium oxide loaded biochar composite material as well as preparation method and application thereof

A nano-magnesium oxide and nano-magnesium hydroxide technology, applied in chemical instruments and methods, water pollutants, other chemical processes, etc., can solve the limited improvement of heavy metal removal efficiency, uneven distribution of nano-magnesium oxide, and nano-magnesium hydroxide. It is easy to aggregate and other problems, and achieves the effects of low preparation cost, restoration of heavy metal pollution in water, and heavy metal pollution in good water.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

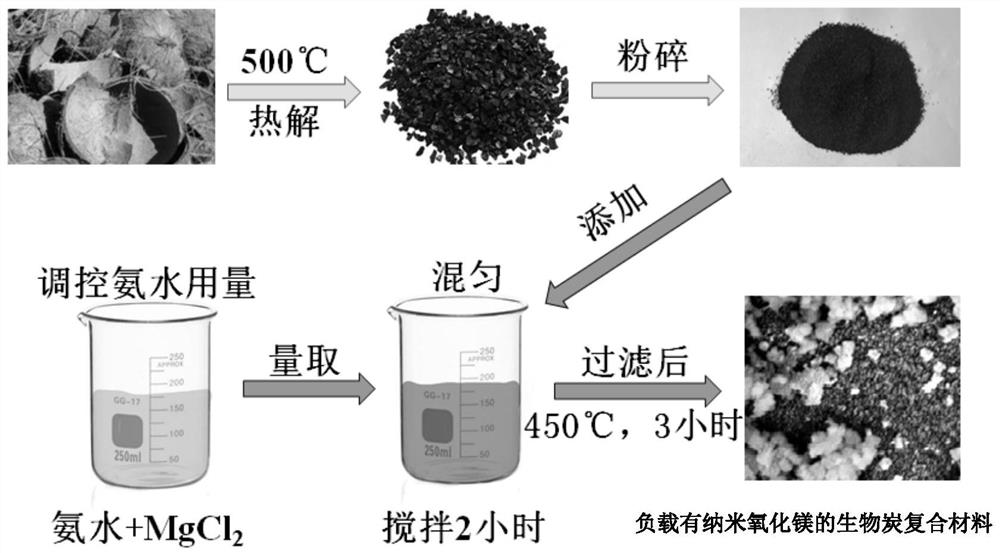

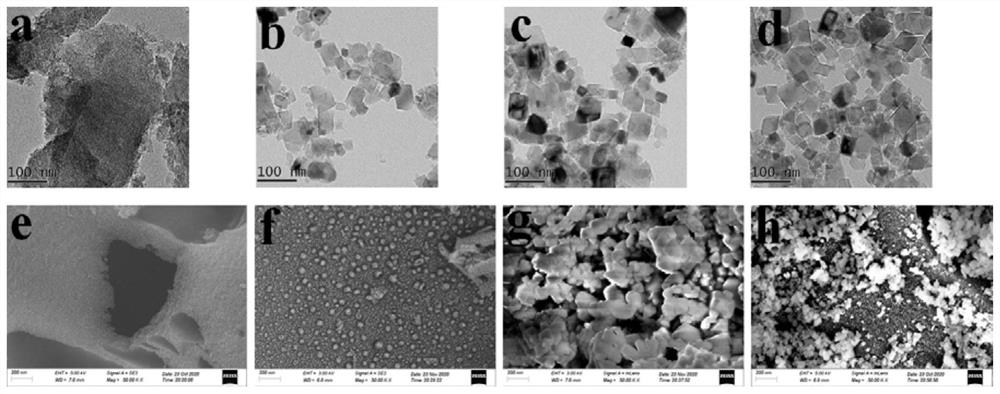

[0031] A biochar composite material loaded with nano-magnesia, the preparation method of which comprises: taking agricultural and forestry waste biomass coconut shells, breaking them and drying them to a constant weight, placing them in a quartz boat, putting them into a tube furnace, and ventilating them with argon. Heat at 500°C (heating rate is 15°C / min) for 4 hours in an environment with an amount of 200sccm to obtain a coconut shell biochar material; mix 1.0g of dried coconut shell biochar material with 100mL of 1mol / L magnesium chloride solution+0.83 Mix mL of ammonia water (28wt%) mixed solution (nano-magnesium hydroxide impregnation solution), stir thoroughly for 2 hours, and filter; take biochar material, dry it in an oven at 65°C to constant weight, put it in a quartz boat, put In a tube furnace, heat at 450°C (heating rate is 15°C / min) for 3 hours in an anoxic environment with an argon flow rate of 200 sccm, so that the nano-magnesium hydroxide loaded on the coconut ...

Embodiment 2

[0034] A biochar composite material loaded with nano-magnesia, the preparation method of which comprises: taking agricultural and forestry waste biomass coconut shells, breaking them and drying them to a constant weight, placing them in a quartz boat, putting them into a tube furnace, and ventilating them with argon. 500°C heating (heating rate is 15°C / min) in an environment of 200sccm for 4 hours to obtain coconut shell biochar material; 1.0g dried coconut shell biochar material was mixed with 100mL of 1mol / L magnesium chloride solution+3.34 Mix mL of ammonia water (28wt%) mixed solution (nano-magnesium hydroxide impregnation solution), stir thoroughly for 2 hours, and filter; take biochar material, dry it in an oven at 65°C to constant weight, put it in a quartz boat, put In a tube furnace, heat at 450°C (heating rate is 15°C / min) for 3 hours in an anoxic environment with an argon flow rate of 200 sccm, so that the nano-magnesium hydroxide loaded on the coconut shell biochar ...

Embodiment 3

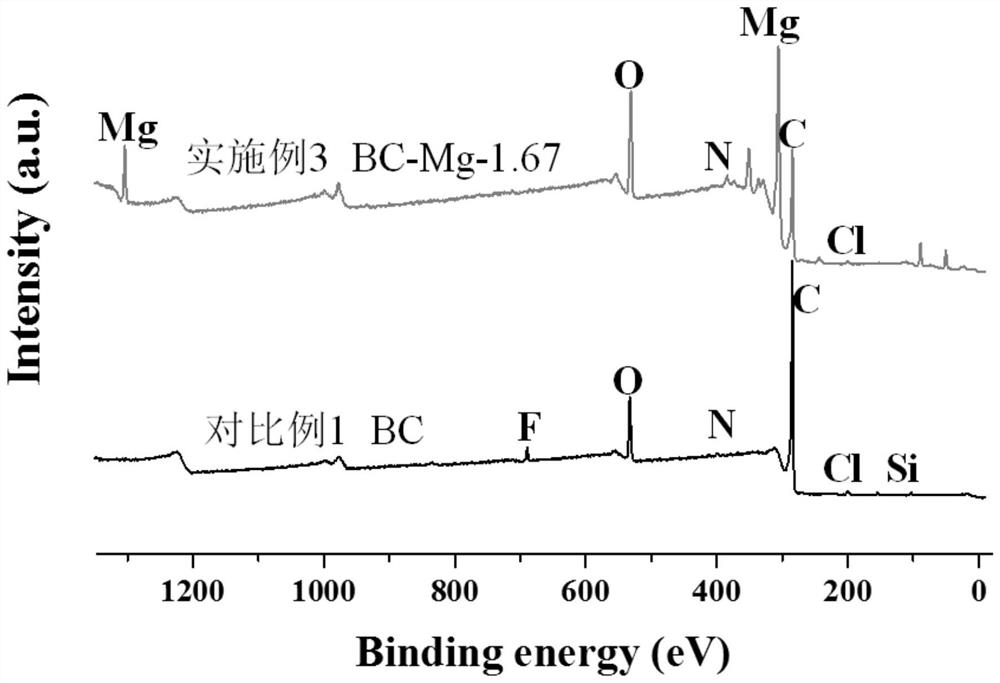

[0036]A biochar composite material loaded with nano-magnesia, the preparation method of which comprises: taking agricultural and forestry waste biomass coconut shells, breaking them and drying them to a constant weight, placing them in a quartz boat, putting them into a tube furnace, and ventilating them with argon. 500°C heating (heating rate is 15°C / min) in an environment of 200sccm for 4 hours to obtain coconut shell biochar material; 1.0g dried coconut shell biochar material was mixed with 100mL of 1mol / L magnesium chloride solution+1.67 Mix mL of ammonia water (28wt%) mixed solution (nano-magnesium hydroxide impregnation solution), stir thoroughly for 2 hours, and filter; take biochar material, dry it in an oven at 65°C to constant weight, put it in a quartz boat, put In a tube furnace, heat at 450°C (heating rate is 15°C / min) for 3 hours in an anoxic environment with an argon flow rate of 200 sccm, so that the nano-magnesium hydroxide loaded on the coconut shell biochar m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com