Complex/PVA composite material as well as preparation method and application thereof

A technology of composite materials and complexes, applied in the direction of luminescent materials, chemical instruments and methods, single-component synthetic polymer rayon, etc., can solve the problems of difficult collection of complexes, poor processability, secondary pollution, etc., and achieve optimal application Performance, promotion of application, high mechanical strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Preparation of matrix membrane

[0046] (1) Preparation of pyrazolyl ring trinuclear Cu(I)(Cl-α) luminescent complex:

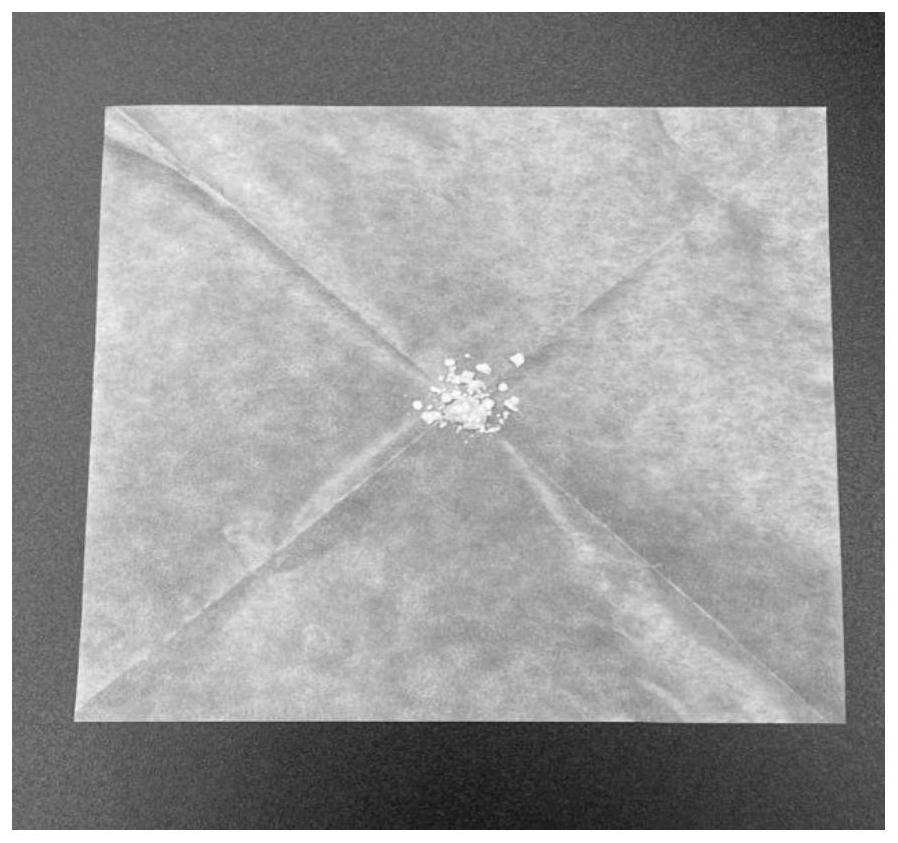

[0047] Cu(NO 3 ) 2 ·3H 2 O (60.4mg), 4-chloropyrazole (51.26mg) was dissolved in ethanol, and then diluted to 25mL with ethanol, so that the Cu(NO 3 ) 2 ·3H 2 The concentrations of O and 4-chloropyrazole were 0.01mol / L and 0.02mol / L, respectively. Then add 2mL of the above solution into a dry and clean hard thick-walled glass tube with an inner diameter of 8mm, and add 1mL of chlorobenzene into it, seal the tube with a hydrogen-oxygen flame machine, and put it in a constant temperature oven . The temperature was raised to 140° C. within 10 minutes, maintained for 12 hours, and then lowered to room temperature at a cooling rate of 5° C. / h. After opening the glass tube, a colorless and transparent Cl-α complex needle crystal was obtained, such as figure 1 shown.

[0048] (2) Preparation of PVA aqueous solution:

[0049] Add PVA powder into hot...

Embodiment 2

[0066] Preparation of matrix fibers

[0067] Step (1) Preparation of pyrazolyl ring trinuclear Cu(I)(Cl-α) luminescent complex and Step (2) preparation of PVA aqueous solution are the same as in Example 1.

[0068] (3) Preparation of matrix fiber:

[0069] Add the Cl-α luminescent complex to the PVA solution, stir for 14 hours, sonicate for 2 hours, and then degas to form a mixed solution, wherein the concentration of the Cl-α luminescent complex is 5 wt%; pour the above mixed solution into a syringe, Then extrude at a constant speed through a pump into a saturated sodium sulfate solution and salt out to form a matrix fiber.

Embodiment 3

[0071] Preparation of 3D printed devices

[0072] Step (1) The preparation of pyrazolyl ring trinuclear Cu(I)(Cl-α) luminescent complex is the same as in Example 1.

[0073] (2) Preparation of PVA aqueous solution:

[0074] Add PVA powder into hot water at 90° C., dissolve, stir, and react for 4 hours to obtain a PVA aqueous solution, wherein the concentration of PVA is 15 wt%.

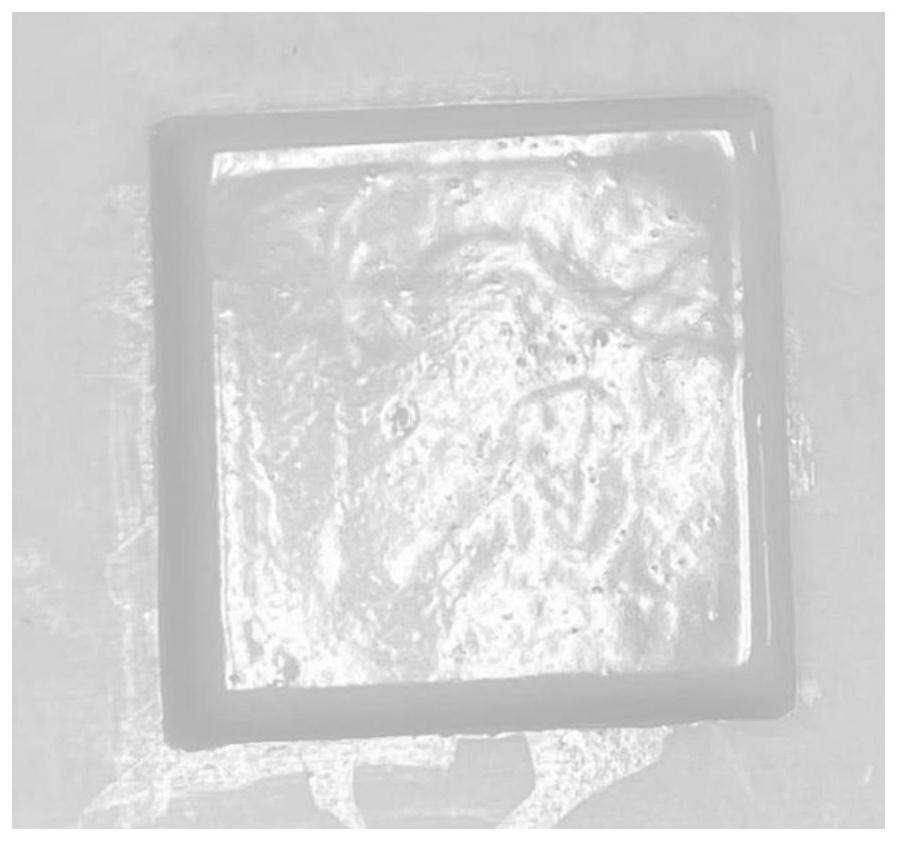

[0075] (3) Preparation of 3D printed devices:

[0076] Add the Cl-α luminescent complex to the PVA solution, stir for 14 hours, ultrasonicate for 2 hours, and then degas to form a mixed solution, in which the concentration of the Cl-α luminescent complex is 2 wt%. The above mixed solution is passed through an extrusion 3D The printer extrudes and prints devices of various shapes in a saturated sodium sulfate solution. Models of 3D printed devices of different shapes such as Figure 10 , Figure 11 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com