Vibrating diaphragm and preparation method and application thereof

A base and solvent technology, applied in the direction of metal material diaphragm, ceramic material diaphragm, diaphragm structure, etc., can solve the problem of complex preparation process, achieve the effect of clear and thorough sound quality, convenient processing and excellent damping performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

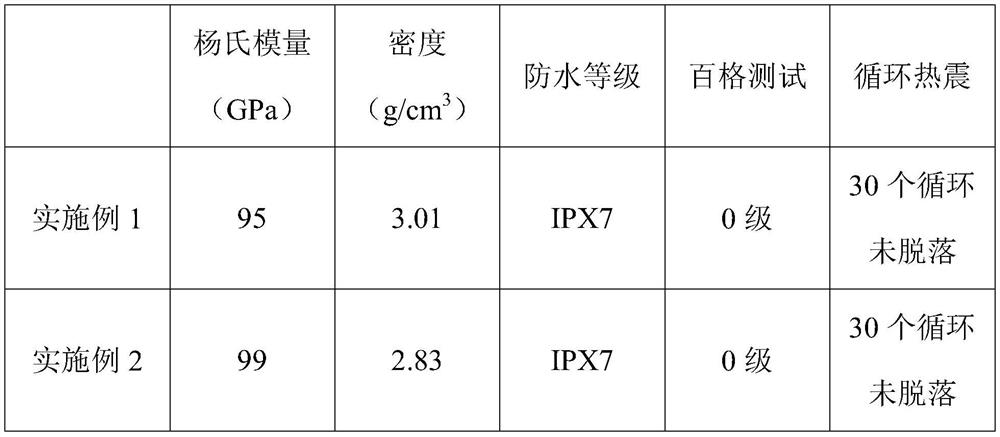

Embodiment 1

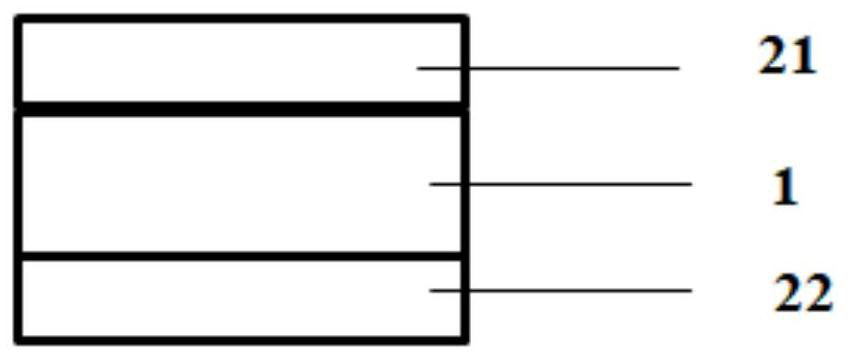

[0061] This embodiment provides a diaphragm, such as figure 1 As shown, the diaphragm includes a base layer 1 (aluminum sheet) and a first ceramic layer 21 (titanium oxide, with a thickness of 5 μm) and a second ceramic layer 22 (titanium oxide, with a thickness of 5 μm) disposed on both sides of the base layer. , the thickness of the diaphragm is 45 μm.

[0062] The preparation method of the above-mentioned diaphragm comprises the following steps:

[0063] (1) Punch the base layer with a thickness of 35 μm into a spherical top shape on the mold, and perform the following pretreatments in sequence: alkali washing and degreasing for 10 minutes, first washing with water, ultrasonication in ethanol for 10 minutes, and second washing with water , dry at 50°C;

[0064] (2) Preparation of precursor solvent A: 30 parts by weight of ceramic layer preparation raw material (tetrabutyl titanate), 20 parts by weight of the first solvent (10 parts of diethanolamine, 10 parts of acetone) ...

Embodiment 2

[0069] This embodiment provides a vibrating membrane, the vibrating membrane includes a base layer (aluminum sheet) and metal oxide (alumina) ceramic layers arranged on both sides of the base layer, the thickness of the vibrating membrane is 45 μm, and the two The thickness of the metal oxide ceramic layers on both sides is 5 μm.

[0070] The preparation method of the above-mentioned diaphragm comprises the following steps:

[0071] (1) Punch the base layer with a thickness of 35 μm into a dome shape on the mold, and perform the following pretreatments in sequence: alkaline washing and degreasing for 15 minutes, first washing with water, ultrasonication in ethanol for 15 minutes, and second washing with water , dry at 50°C;

[0072] (2) Preparation of precursor solvent A: 60 parts by weight of ceramic layer preparation raw materials (aluminum chloride hexahydrate and aluminum nitrate nonahydrate in a mass ratio of 1:1), 20 parts by weight of the first solvent (a mass ratio of...

Embodiment 3

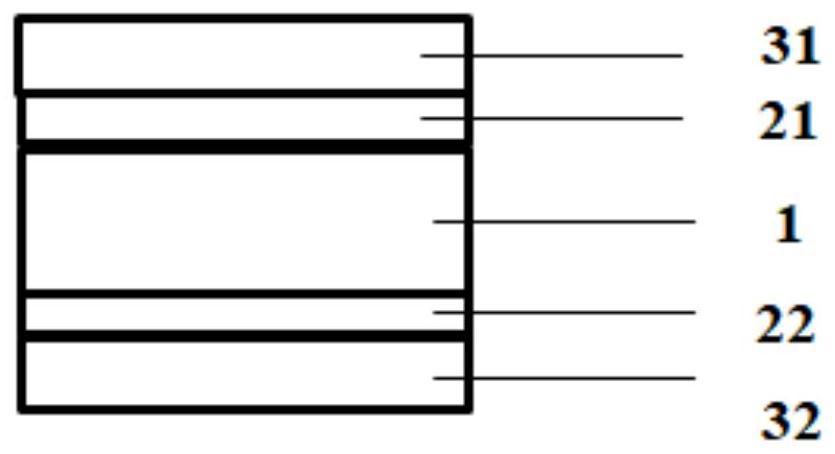

[0077] This embodiment provides a diaphragm, such as figure 2 As shown, the diaphragm includes a third ceramic layer 31 (titanium oxide, with a thickness of 2.5 μm), a first ceramic layer 21 (aluminum oxide, with a thickness of 1.5 μm), and a base layer 1 (aluminum alloy, purchased from Shuangzhixin Electroacoustic Technology Co., Ltd.), the second ceramic layer 22 (aluminum oxide, with a thickness of 2 μm) and the fourth ceramic layer 32 (titanium oxide, with a thickness of 2 μm), and the thickness of the diaphragm is 48 μm.

[0078] The preparation method of the above-mentioned diaphragm comprises the following steps:

[0079] (1) Punch the base layer with a thickness of 40 μm into a spherical top shape on the mold, and perform the following pretreatments in sequence: alkali washing and degreasing for 12 minutes, first washing with water, ultrasonication in ethanol for 13 minutes, and second washing with water , dry at 50°C;

[0080] (2) Preparation of precursor solvent A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com